Water dividing oil purifier for fuel used by ship

A water-separating oil purifier and fuel oil technology, which is applied in the field of fuel oil purification, can solve the problems affecting the normal operation of ships and ships, high system maintenance time and cost, and cannot guarantee the continuous operation of ships, etc., and achieves simple and convenient operation and maintenance. Vibration Small, novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

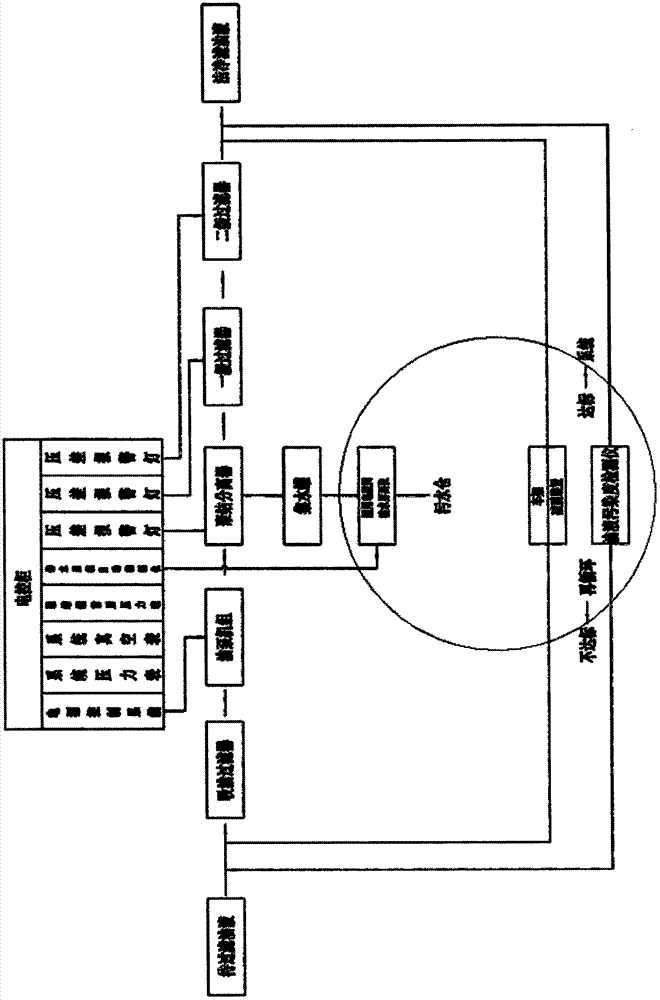

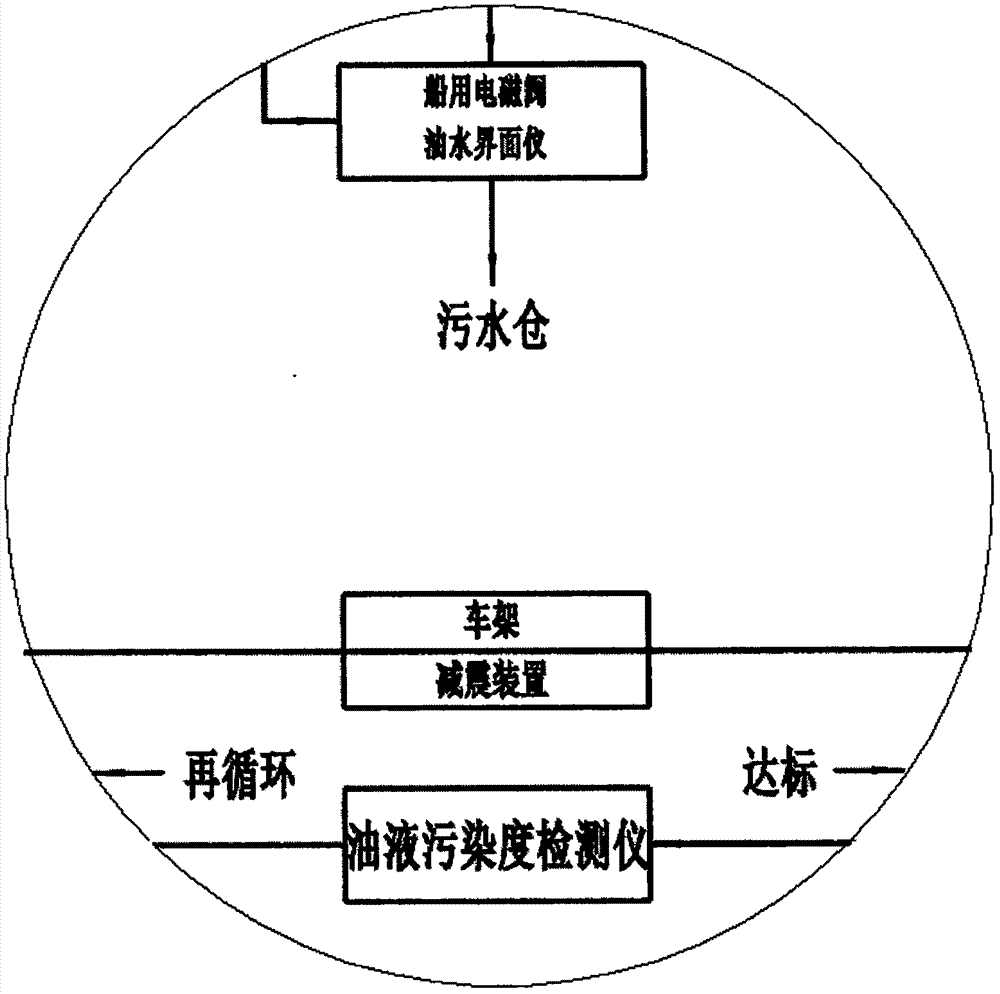

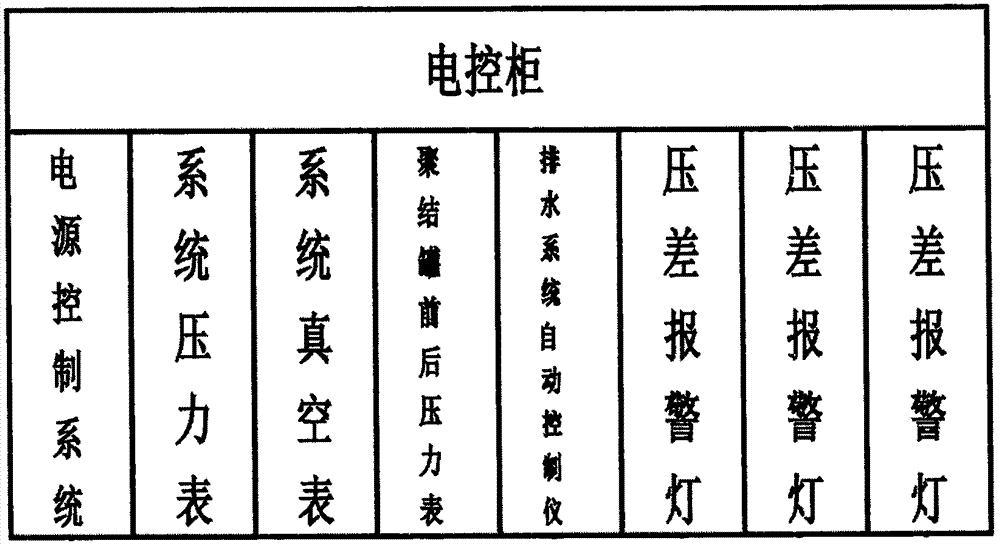

[0012] Such as figure 1 , figure 2 , image 3 A fuel water separator and oil purifier for ships is shown, including a water separator and oil purifier system, and the water separator and oil purifier system includes oil with filter, oil suction filter, oil pump unit, coalescing separator, and water collection tank , marine solenoid valve oil-water interface instrument, sewage tank, primary filter, secondary filter, oil pollution degree detector, electric control cabinet; oil suction filter, oil pump unit, coalescence separator primary filter, secondary The first-stage filter is connected in series through pipelines, the water collection tank, the marine solenoid valve oil-water interface instrument, and the sewage tank are sequentially connected in series through pipelines, the marine solenoid valve oil-water interface instrument is electrically connected to the electric control cabinet through wires, and the oil pollution degree detector is connected in parallel Connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com