Acoustoelectric bimodal fusion measuring method of two-phase flow process parameters

A technology of process parameters and measurement methods, applied in fluid velocity measurement, measurement device, velocity/acceleration/impact measurement, etc., can solve the problem of inability to obtain an accurate and comprehensive description of multiphase flow, many parameters to be measured, and the difficulty of accurate parameter testing. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

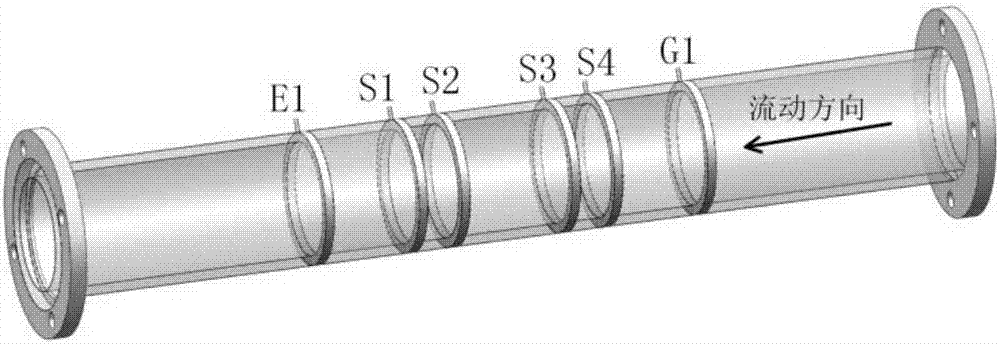

[0074] Conductivity sensor structure such as figure 1 As shown, it consists of six annular electrodes arranged in the axial direction, among which 1, 6 are excitation electrodes, and 2, 3, 4, 5 are measurement electrodes. The method of current excitation voltage measurement is adopted. The excitation signal is a square wave signal with a frequency of 20kHz. By injecting a constant current into electrode 1 and grounding electrode 6, a stable electrical measurement field can be formed between electrodes 1 and 6. The potential difference between them is proportional to the fluid impedance distributed therebetween, and the average resistivity of the two-phase flow between them can be obtained by measuring the potential difference between the electrode pair 2-3, the electrode pair 3-4 and the electrode pair 4-5 respectively. The impedance of the oil-water two-phase flow has a corresponding relationship with the phase distribution, so the phase holdup can be measured by measuring th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com