A device and method for testing the tangential stiffness of the joint surface of the wheel disc

A technology of tangential stiffness and joint surface, which is used in measuring devices, using stable tension/pressure to test the strength and strength characteristics of materials, etc., to achieve the effects of easy implementation, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] A specific embodiment will be described in detail below in conjunction with the accompanying drawings.

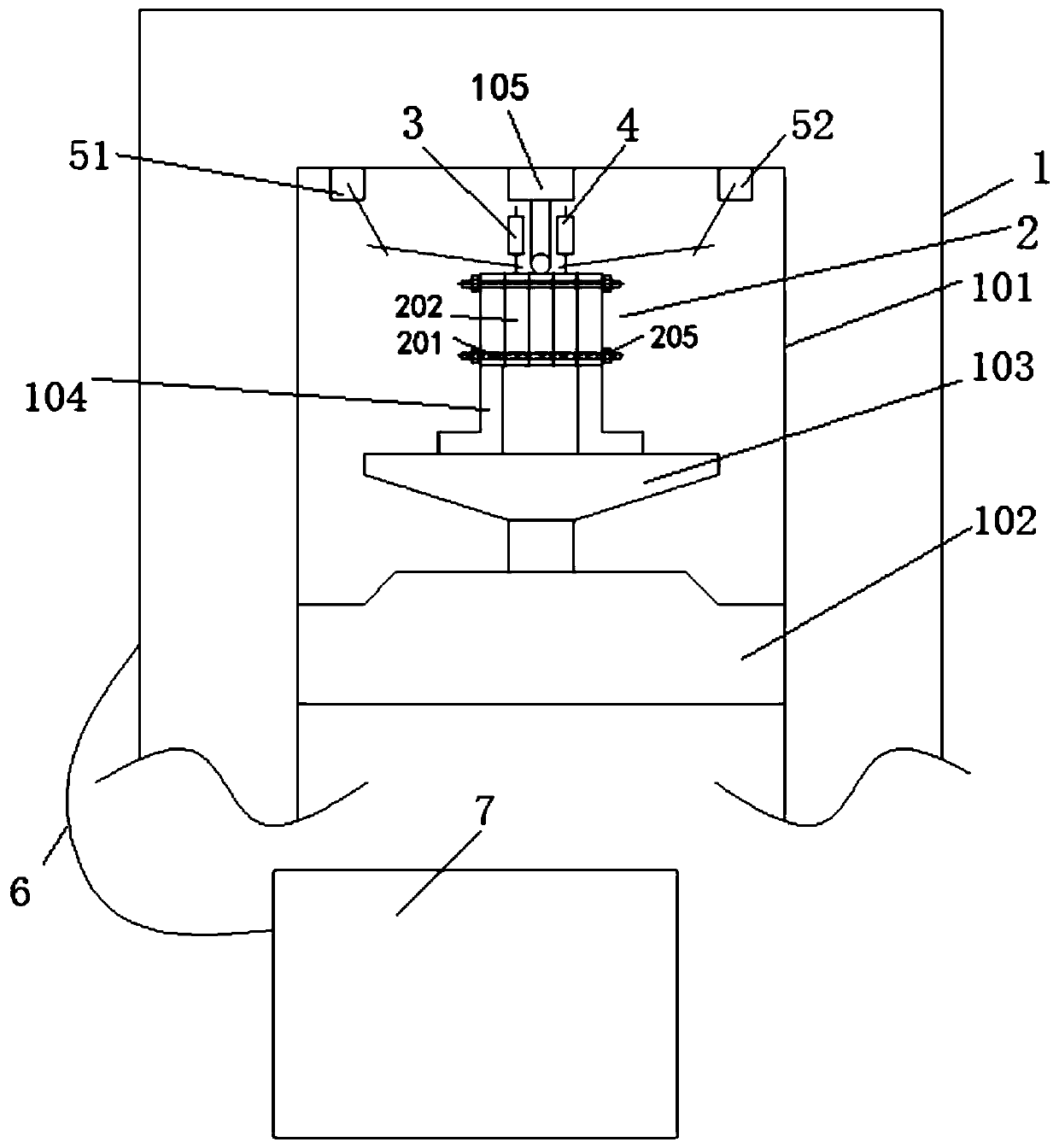

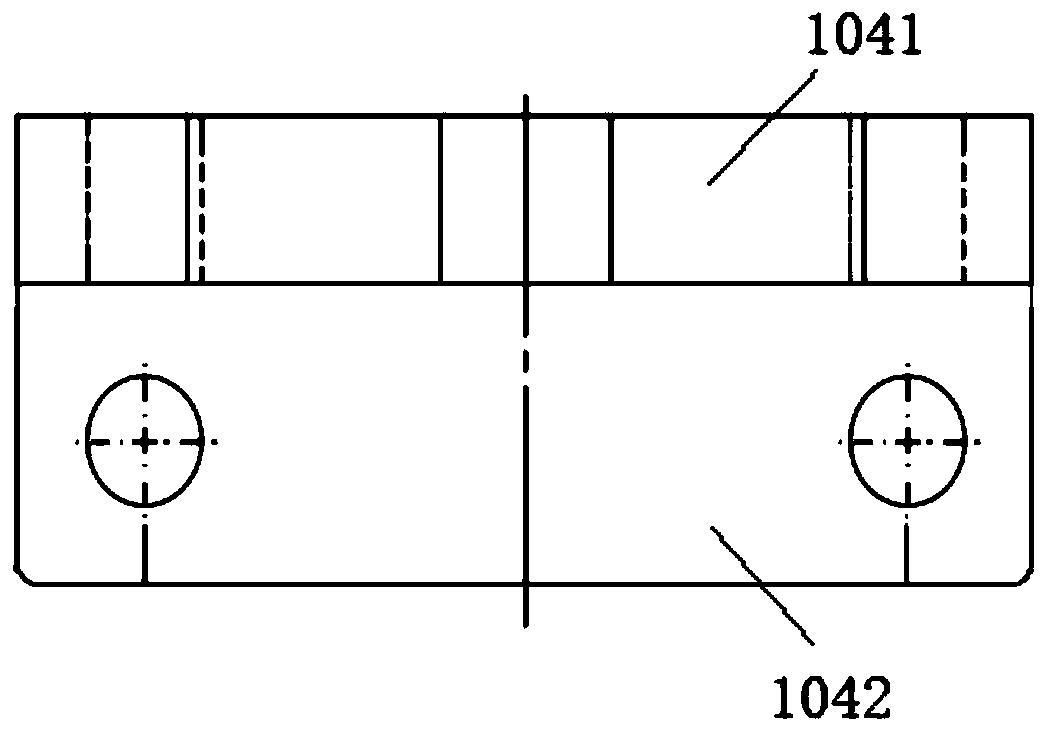

[0057] Please refer to figure 1 , a device for testing the tangential stiffness of the joint surface of the wheel disc, comprising a universal testing machine 1, a tie rod rotor 2, a digital display dial indicator 1 3, a digital display dial indicator 2 4 and a computer 7, and the universal testing machine 1 has its own The pressure sensor is connected with computer 7 by data line 6, can directly read pressure value from computer 7; The first 3 and the digital display dial indicator two 4 are located on both sides of the upper pressure head 105, the middle part of the frame 101 is provided with a movable beam 102, and two support blocks 104 are arranged at intervals on the beam 102, and the tie rod rotor 2 is horizontally set up on the two supports. On the block 104, the tie rod rotor 2 is located directly below the upper indenter 105. During the test, the crossbeam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com