Stepped liquid labyrinth sealing element

A labyrinth seal and step-type technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of difficult to achieve precision and sealing effect, and achieve the effect of not easy to pass, strong toughness, enhanced viscosity and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these examples are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention All modifications of the valence form fall within the scope defined by the appended claims of the present application.

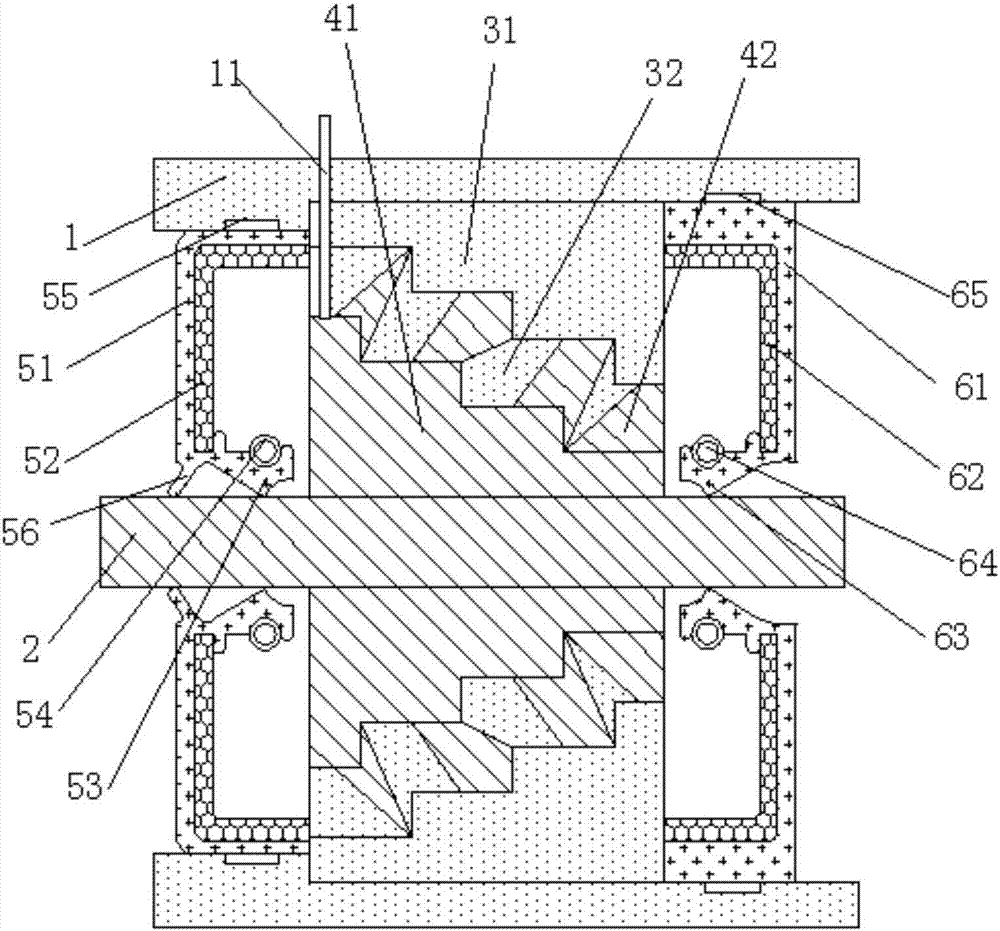

[0012] A stepped liquid labyrinth seal such as figure 1 As shown, it includes a housing 1, a rotating shaft 2, a first type ring 31, a second type ring 41, an outer seal assembly and an inner seal assembly, the inner seal assembly and the outer seal assembly are arranged in the housing 1 from the inside to the outside, and the The inner seal assembly and the outer seal assembly are located between the rotating shaft 2 and the outer casing 1; a liquid labyrinth area i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com