Prefabricated superimposed sheet, seam structure of prefabricated superimposed sheet and seam squeezing concrete mortar

A technology of concrete mortar and laminated slabs, which is applied in the direction of floor slabs, building components, building structures, etc., can solve problems such as cracks at joints, achieve the effects of improving strength and stability, increasing contact area, and preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

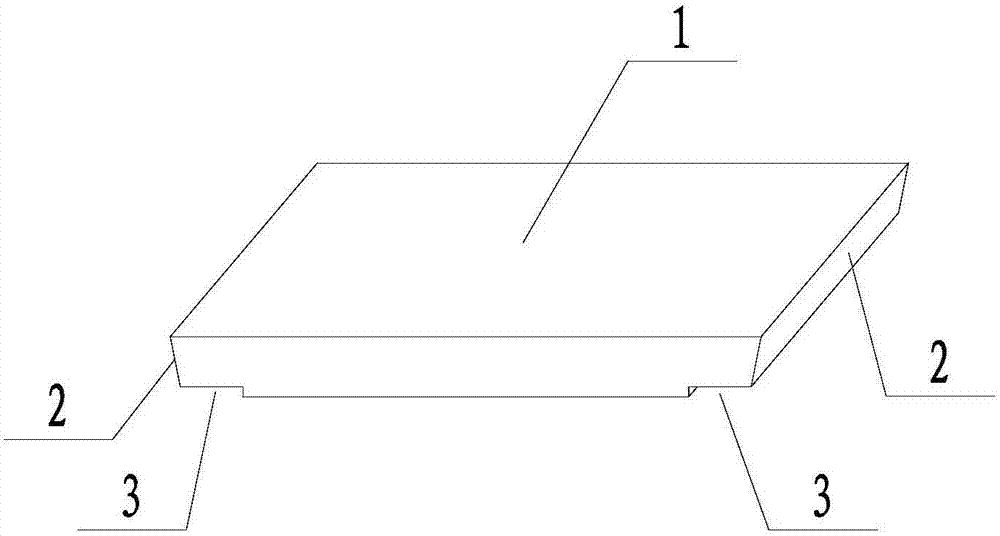

[0032] Such as figure 1 The shown prefabricated laminated board includes a board body 1, and the side surface of the board body 1 is provided with a slope 2 inclined from top to bottom toward the inner direction of the board body 1, and the lower edge of the slope 2 is higher than the bottom surface of the board body 1; A notch 3 located on the bottom surface of the plate body 1 is provided below each inclined surface 2 , and the lower edge of the inclined surface 2 is located in the plane where the top surface of the notch 3 is located. The included angle between the slope 2 and the vertical direction is 10°. The width of the notch 3 is 55 mm. The inside of the board body 1 is provided with a number of distribution ribs 7 which criss-cross.

Embodiment 2

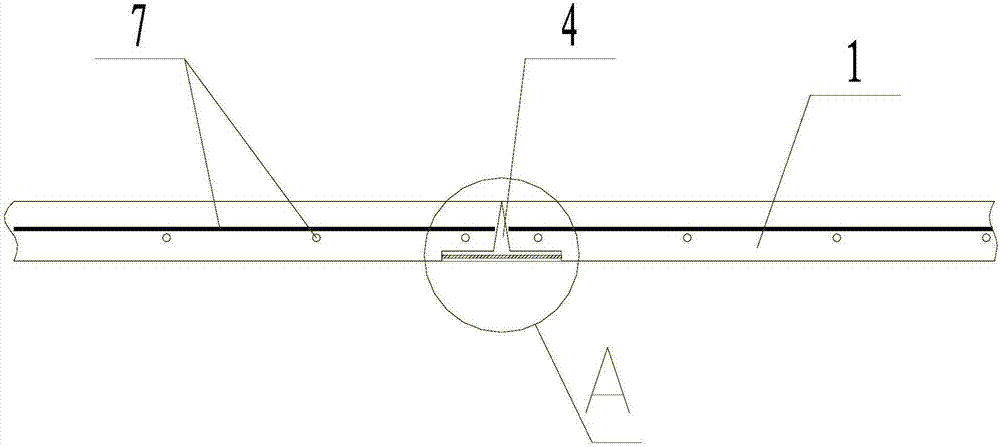

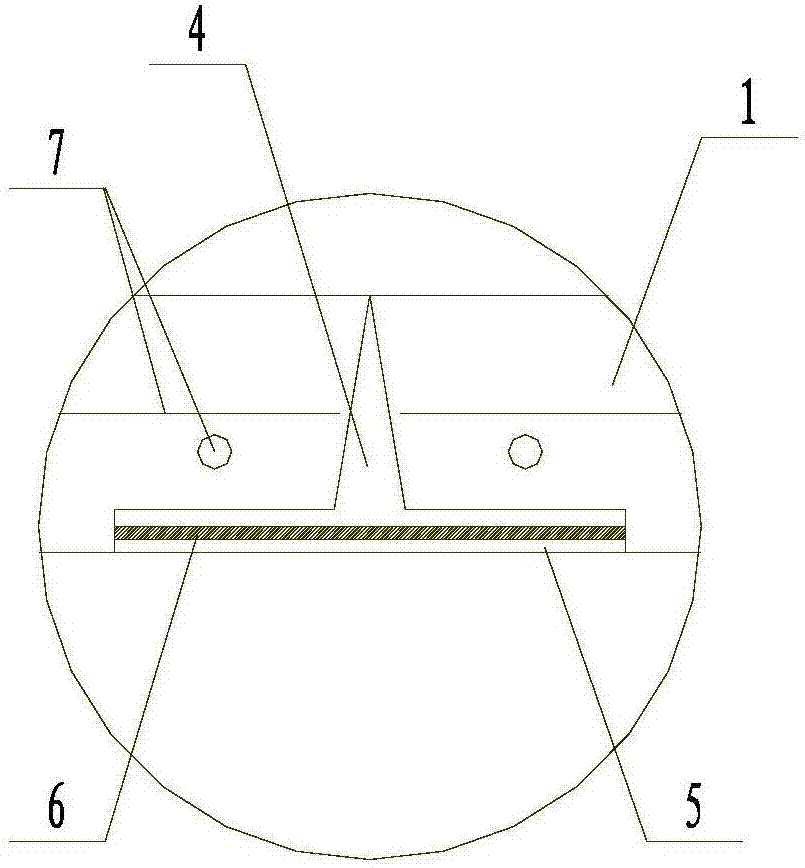

[0034] Such as figure 2 and image 3 A prefabricated laminated panel seam structure is shown, including two adjacent panels 1, the slopes of the two panels 1 face each other, and the opposite two slopes are assembled into a triangular cavity 4, and the bottom of the triangular cavity 4 is a square Cavity 5, the square cavity 5 is formed by joining two opposite gaps on the two boards 1; the triangular cavity 4 and the square cavity 5 are filled with concrete mortar. A mesh extension layer 6 is arranged inside the square cavity 5 , and the mesh extension layer 6 is parallel to the surface of the plate body 1 . The mesh extension layer 6 is a glass fiber mesh or a gauze mesh. The two ends of the mesh extension layer 6 are respectively fixed on the side walls of the two gaps. The inside of the board body 1 is provided with a number of distribution ribs 7 which criss-cross. The invention greatly increases the contact area between the concrete mortar and the laminated plates on...

Embodiment 3

[0036] A concrete mortar for extrusion, comprising the following components by weight: 200 parts of ordinary portland cement, 5 parts of redispersible latex powder, 200 parts of silica sand, 200 parts of superfine fly ash, 8 parts of polyacrylamide, 20 parts of 2-acrylamide-2-methylpropanesulfonic acid, 8 parts of copolymerized acrylic acid, 5 parts of acrylamide, and 10 parts of hydroxypropyl methylcellulose; wherein the particle size of ultrafine fly ash is 120 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com