Waterproof anti-cracking footpath

A trail and anti-cracking technology, which is applied to roads, roads, buildings, etc., can solve the problems of being easily cracked by cars and easy water accumulation on trails, so as to prevent bricks from cracking and increase the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings:

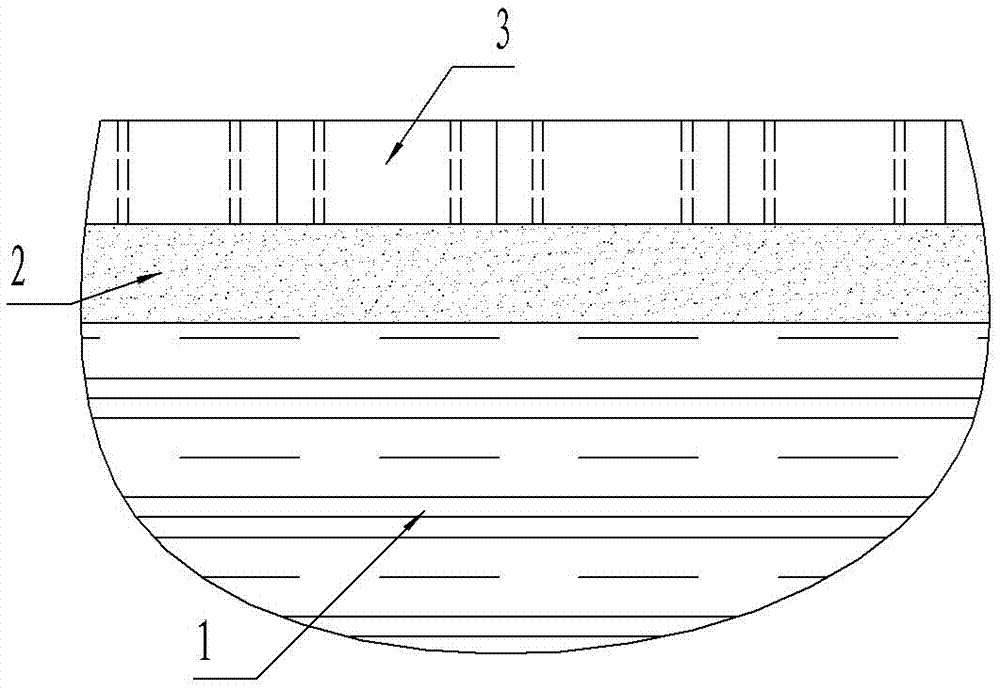

[0012] Such as figure 1 , figure 2 The shown waterproof and anti-cracking trail includes a layer of bricks embedded on the soil layer 1 through the connecting layer 2. The connecting layer 2 is black sand, and the brick layer is laid on the connecting layer 2, and it has excellent water permeability. The black sand is used as the connecting layer 2, and the brick layer is directly spliced on it, without cement connection, so that the rain can smoothly penetrate from the black sand to the soil layer 1, without water accumulation, and convenient for passers-by to walk on rainy days. The brick layer is formed by splicing a plurality of bricks 3 made of clay. The upper surface of the brick 3 after installation is a regular triangle, and the three edges of the brick 3 are provided with protrusions embedded with other bricks 3 The edge 3-1 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com