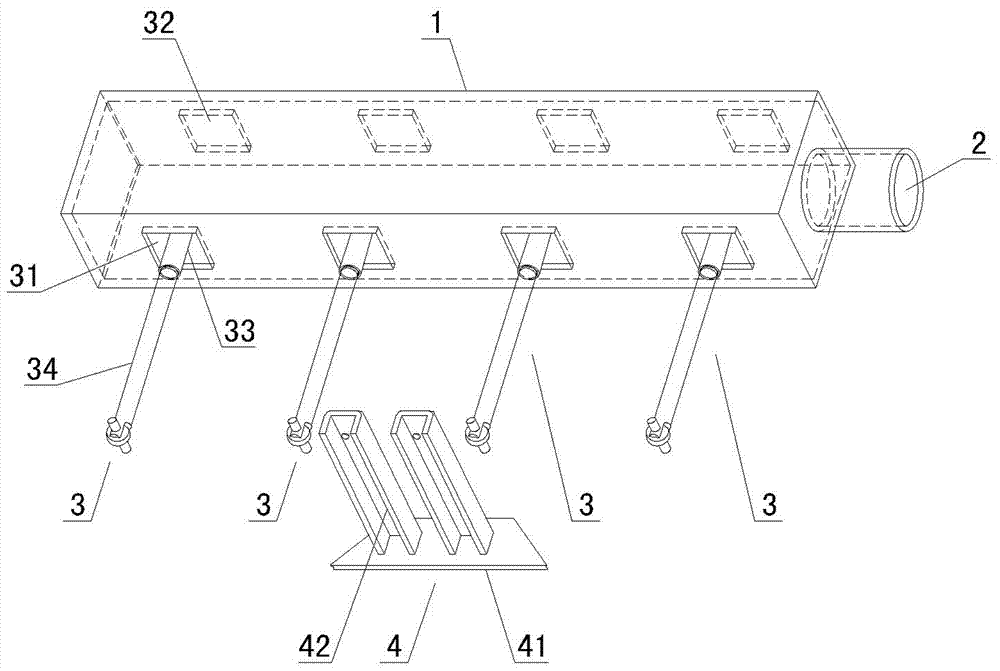

Efficient metal cutting and dedusting device

A metal cutting and dust removal device technology, applied in auxiliary devices, metal processing equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor dust removal and cutting effect, reduced air volume and reduced wind force, and achieves obvious dust collection effect, The effect of strong ventilation and high ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

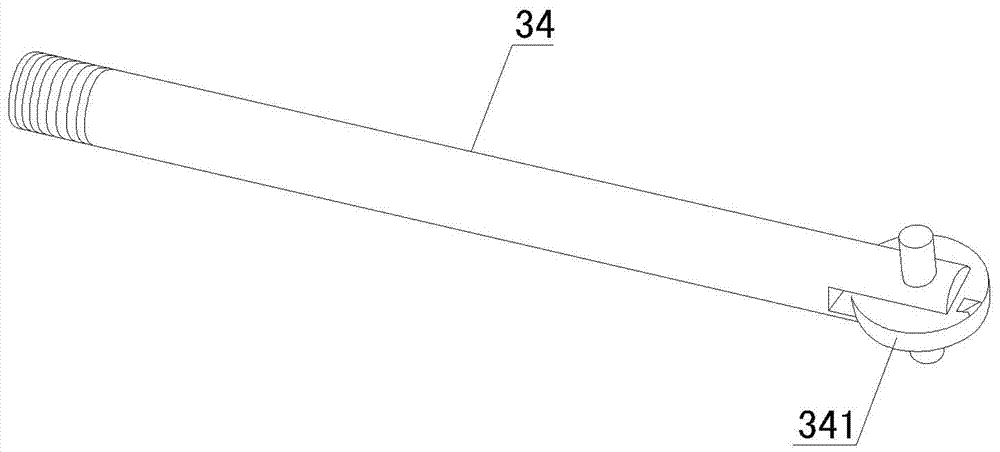

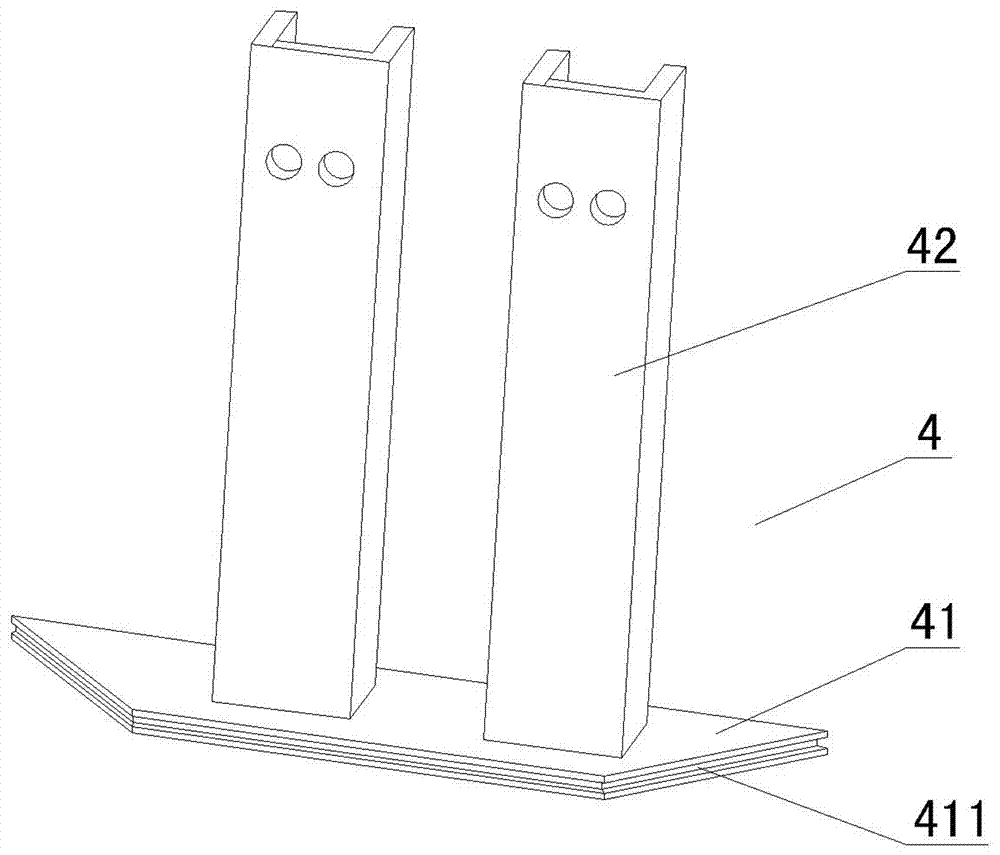

[0026] Use plasma cutting equipment with a format of 6000mm×2000mm to cut 80mm thick carbon steel plate. The circular air outlet 2 is connected to the dust removal host through a stretchable plastic hose, and the workpiece to be cut is placed on a cutting platform away from the circular air outlet 2. When cutting, the cutting truss walks above the workpiece, and the ladder frame 4 connected with it pushes the front baffle 333 and the rear baffle 334 away from the original position through the push rod 34, so that the front baffle 333 and the rear baffle 334 are in contact with the air duct 1 gaps between. The dust generated during cutting enters the air duct 1 through the generated gap, and is finally sucked into the dust removal host after being transported to achieve the cutting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com