Stirring radius variable chlorination reaction kettle

A technology of chlorination reaction kettle and stirring radius, which is applied in chemical/physical/physical chemical fixed reactors, mixers with rotating stirring devices, chemical/physical/physical chemical processes, etc., and can solve the problem of increasing equipment footprint Area, increased production cost, and the stirring radius of the stirring blade cannot be changed, etc., to achieve good reaction effect, improve practicability, and good stirring reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

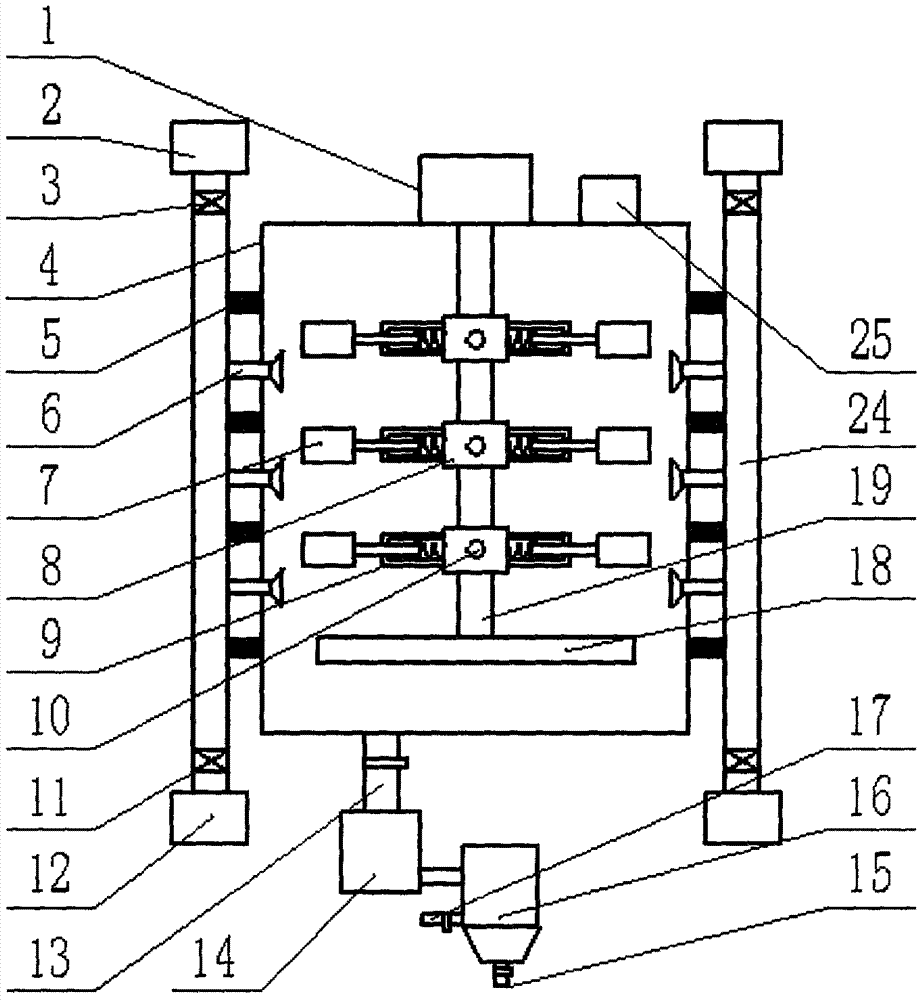

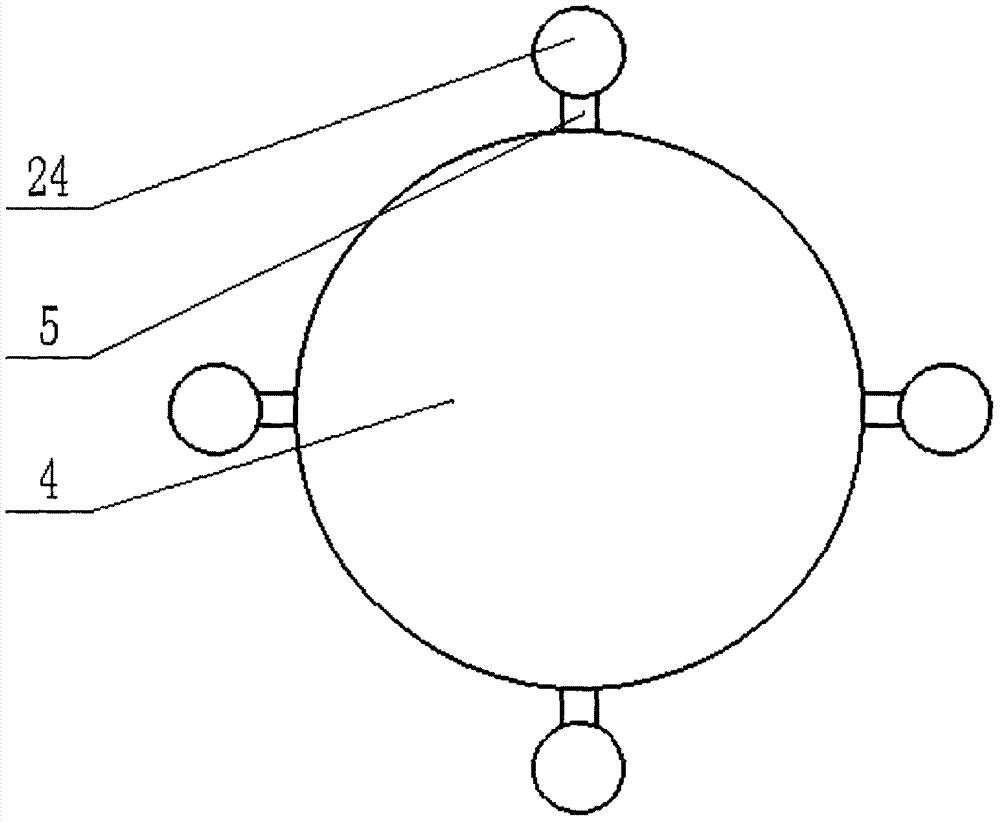

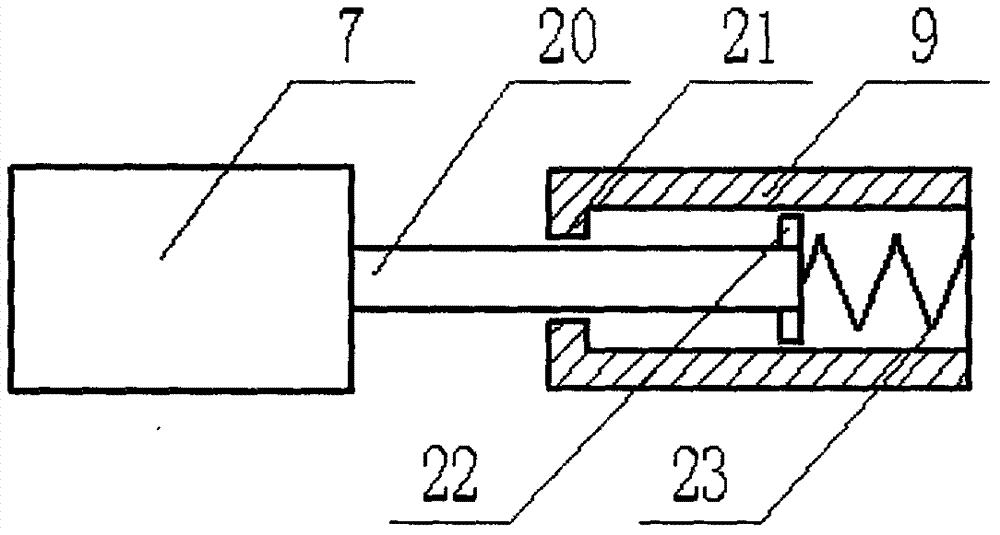

[0018] see Figure 1-3 , a chlorination reactor whose stirring radius can vary, comprising a kettle body 4, a pipeline 24 and a motor 1, the top of the upper end of the kettle body 4 is fixedly installed with a motor 1, and the output shaft of the motor 1 is connected with a stirring shaft 19; The stirring shaft 19 is provided with a plurality of shaft sleeves 8, and both sides of the shaft sleeve 8 are provided with an internal hollow sleeve 9, one side of the sleeve 9 is fixedly connected with the shaft sleeve 8, and the other side of the sleeve 9 is provided with There is an opening, and the opening of the sleeve 9 is provided with a rib 21; a telescopic rod 20 is slidably arranged in the sleeve 9, and the side of the telescopic rod 20 facing the shaft sleeve 8 is fixedly connected with a retaining ring 22, and the telescopic rod 20 faces the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com