High-frequency chain matrix type inverter topology with front stage being dual Buck-Boost inverters and modulation method thereof

A matrix converter and inverter technology, which is applied in the output power conversion device, the conversion of AC power input to DC power output, electrical components, etc. problem, to achieve the effect of wide application scalability, easy implementation, and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described below in conjunction with accompanying drawing:

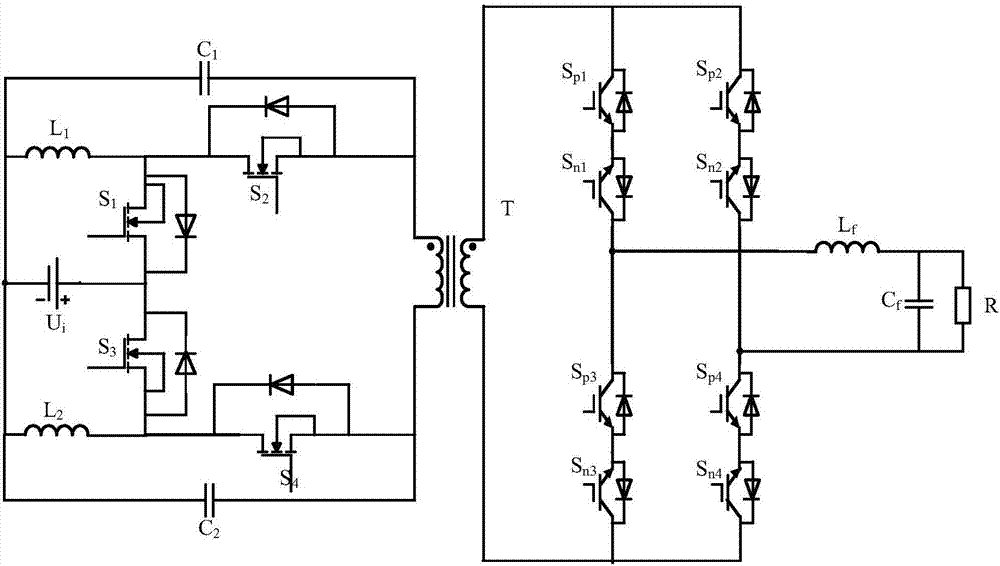

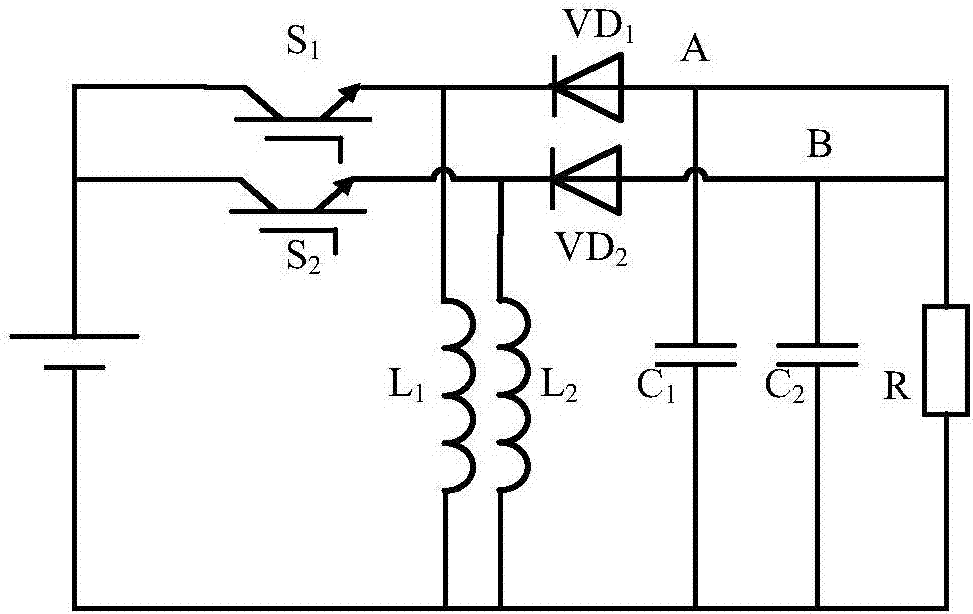

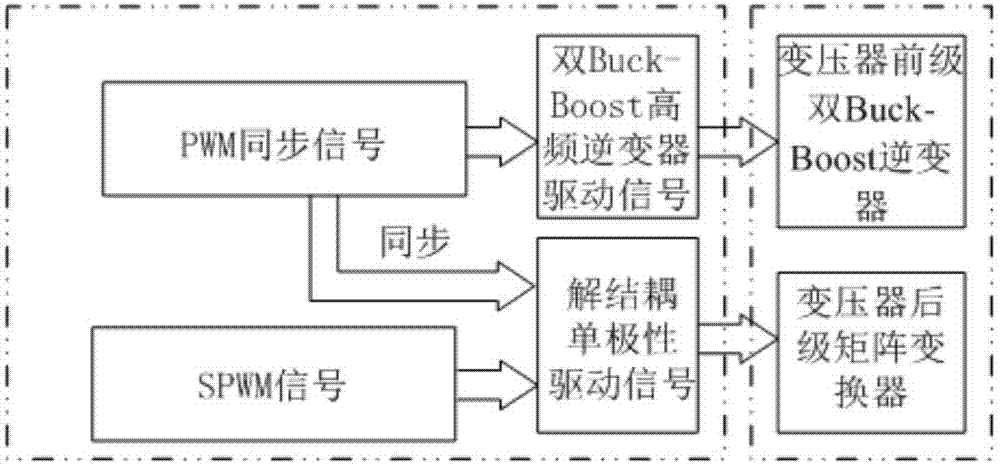

[0028] The topology of the high-frequency chain matrix inverter with double Buck-Boost front stage in the present invention is composed of double Buck-Boost inverters, high-frequency transformer T, matrix converter, and LC type filter connected in sequence; The inverter circuit is a double Buck-Boost circuit, and the output of the two sets of Buck-Boost is differenced to obtain a positive and negative alternating high-frequency square wave, which is coupled to the secondary side of the transformer by a high-frequency transformer and modulated by a matrix converter in the rear stage of the transformer. , output power frequency sinusoidal voltage by filter.

[0029] The front stage is a dual Buck-Boost inverter circuit with a DC input voltage U i , power switch tube S 1 , power switch tube S 2 , power switch tube S 3 , power switch tube S 4 , inductance L 1 , inductance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com