Battery PACK box structure capable of conducting heat, exhausting air and resisting water

A battery and gas sheet technology is applied in the field of battery pack box structure that can conduct heat, exhaust and waterproof. Effects of light weight, reduced production cost, and easy gas exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

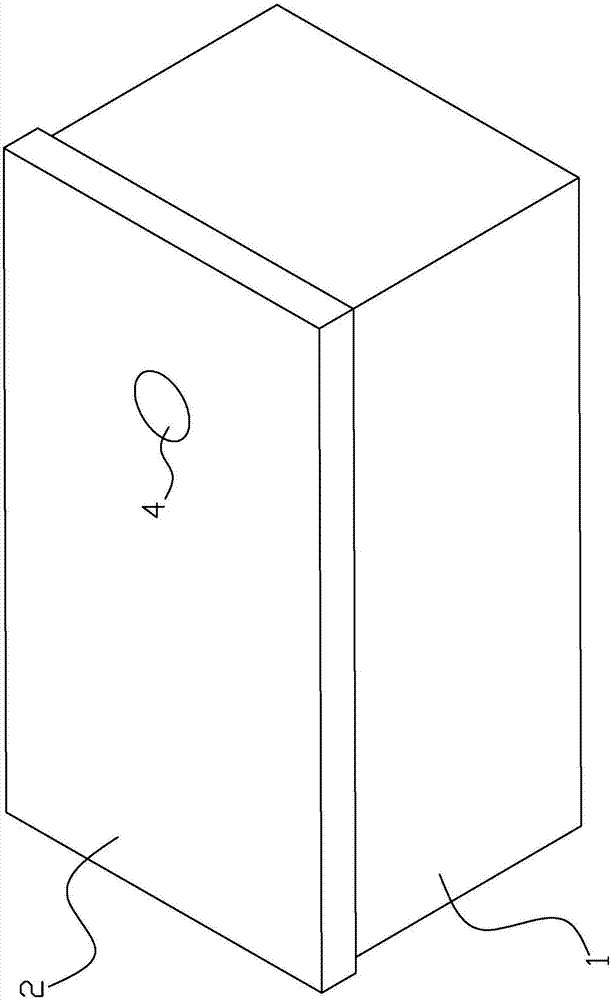

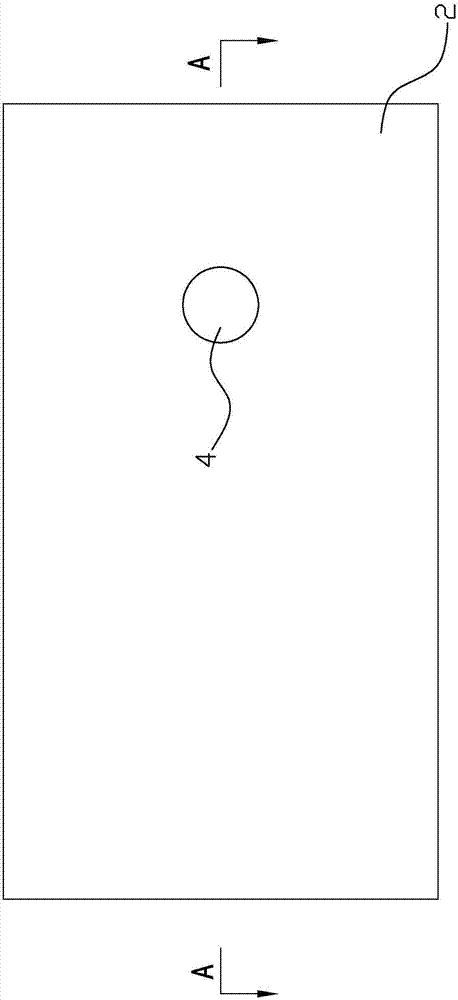

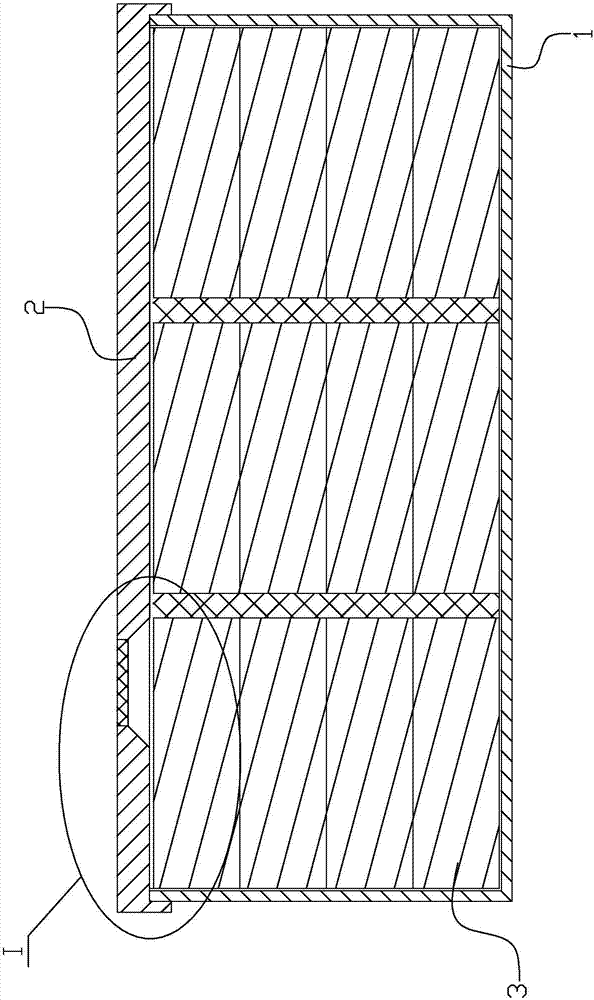

[0028] like Figure 1 to Figure 7 As shown, the heat conduction, exhaust and waterproof battery PACK box structure of this embodiment includes a box body 1 and a box cover 2 capable of accommodating a battery 3, and the box cover 2 is sealed and placed on the box body 1. The box cover 2 is embedded with an air guide sheet 4 made of corrosion-resistant PP material, and the air guide sheet 4 can discharge the gas in the box body 1 from the air guide sheet 4 to the outside of the box body 1 under a set pressure. The box body 1 and the box cover 2 are made of corrosion-resistant PP carbon fiber composite material, and the air guiding sheet 4 is welded together with the box cover 3 by high frequency. The thickness of the air guiding sheet 4 is smaller than that of the lid 2 , the top surface of the air guiding sheet 4 is flush with the top surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com