Protection type precise setting-out position finder

A locator and precise technology, applied in the direction of instruments, measuring instruments, measuring devices, etc., can solve the problems of difficult maintenance, insufficient reliability of the fixing method, and increasing the cumbersome installation, so as to achieve a reliable structure, an uncomplicated structure, and reduced The effect of small assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

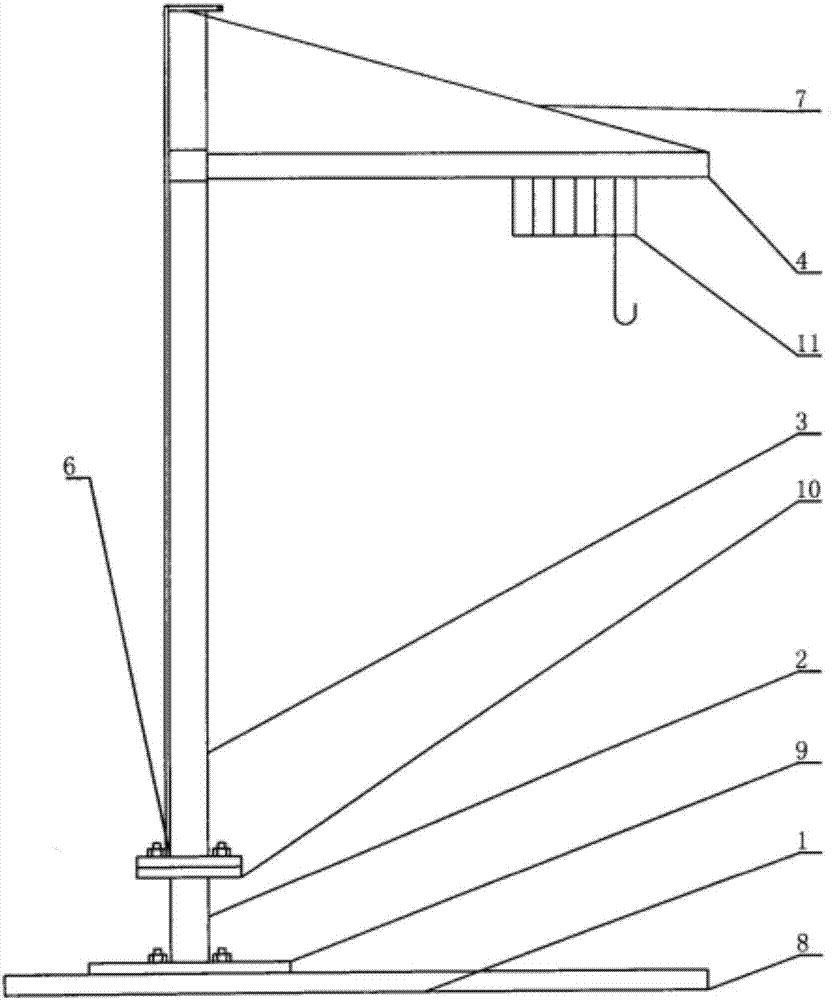

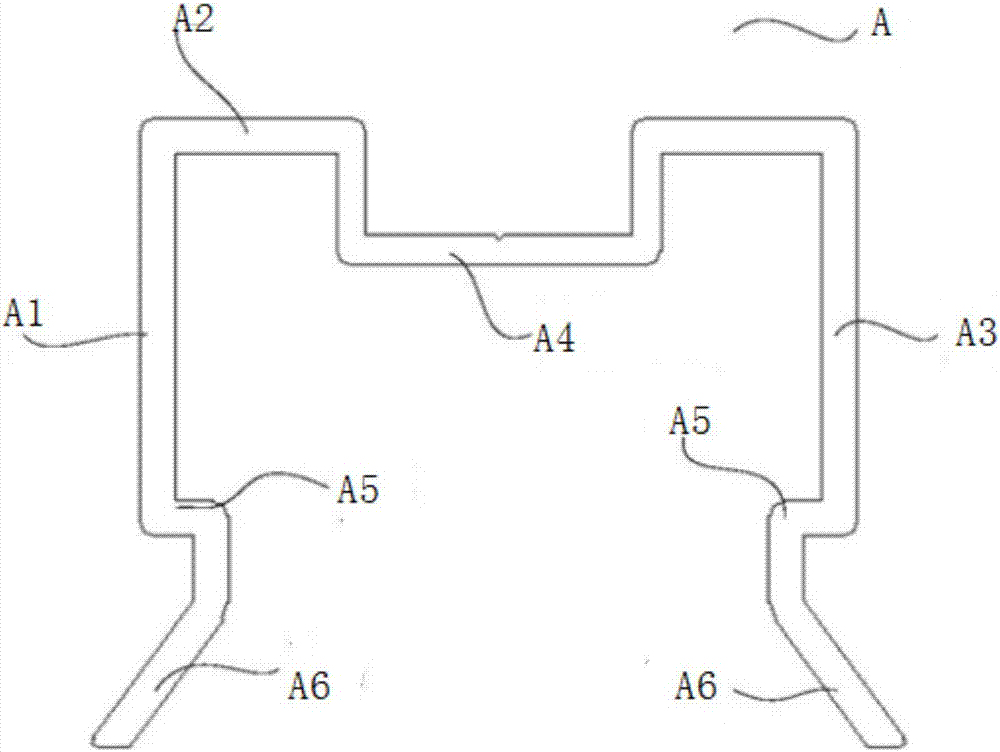

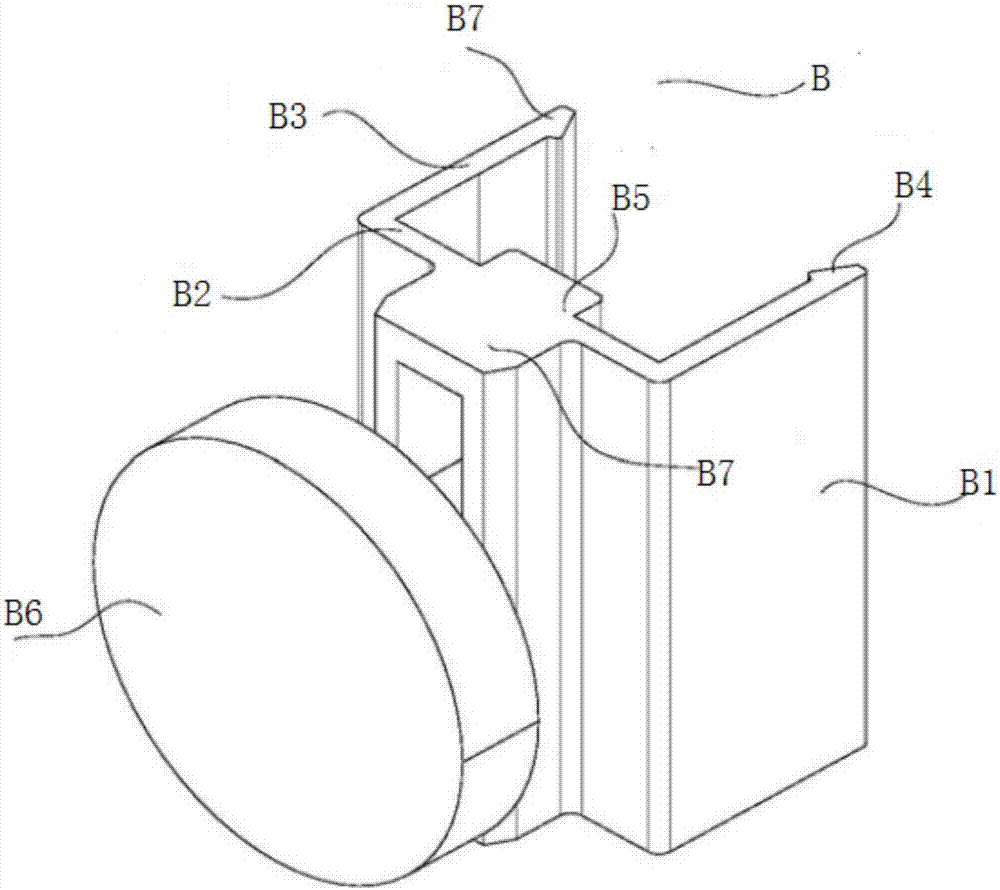

[0054] Such as Figure 1-Figure 5 As shown, the projection-type accurate wire-laying locator of the present embodiment includes: a cylindrical cone rod 3, a square base 1, a wire reel 7 for vertically telescopic wire-laying, a vertical wire 4, and a wire for connecting the vertical wire. The crossbeam 5, the spirit level positioner 6 and the four adjustment screws 2 for adjusting the verticality;

[0055] Wherein, the bottom end of the cylindrical cone rod 3 is inserted into the square base 1;

[0056] The four corners of the upper surface of the square base 1 are respectively provided with the four adjusting screws 2 for adjusting verticality;

[0057] The top of the cylindrical cone rod 3 is vertically connected with the beam 5 for connecting vertical lines;

[0058] The level locator 6 is set under the cylindrical cone rod 3;

[0059] Both ends of the vertical line 4 are respectively connected to the square base 1 and the beam 5 for connecting the vertical line;

[0060...

Embodiment 2

[0082] The projection-type accurate wire-laying positioning instrument of this embodiment includes: a cylindrical cone rod 3, a square base 1, a wire reel 7 for vertical telescopic wire-laying, a vertical wire 4, and a crossbeam 5 for connecting the vertical wire , a spirit level locator 6 and four adjustment screws 2 for adjusting verticality;

[0083] Wherein, the bottom end of the cylindrical cone rod 3 is inserted into the square base 1;

[0084] The four corners of the upper surface of the square base 1 are respectively provided with the four adjusting screws 2 for adjusting verticality;

[0085] The top of the cylindrical cone rod 3 is vertically connected with the beam 5 for connecting vertical lines;

[0086] The level locator 6 is set under the cylindrical cone rod 3;

[0087] Both ends of the vertical line 4 are respectively connected to the square base 1 and the beam 5 for connecting the vertical line;

[0088] The wire reel 7 for vertical telescopic pay-off is c...

Embodiment 3

[0114] The projection-type accurate wire-laying positioning instrument of this embodiment includes: a cylindrical cone rod 3, a square base 1, a wire reel 7 for vertical telescopic wire-laying, a vertical wire 4, and a crossbeam 5 for connecting the vertical wire , a spirit level locator 6 and four adjustment screws 2 for adjusting verticality;

[0115] Wherein, the bottom end of the cylindrical cone rod 3 is inserted into the square base 1;

[0116] The four corners of the upper surface of the square base 1 are respectively provided with the four adjusting screws 2 for adjusting verticality;

[0117] The top of the cylindrical cone rod 3 is vertically connected with the beam 5 for connecting vertical lines;

[0118] The level locator 6 is set under the cylindrical cone rod 3;

[0119] Both ends of the vertical line 4 are respectively connected to the square base 1 and the beam 5 for connecting the vertical line;

[0120] The wire reel 7 for vertical telescopic pay-off is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com