Water-tank-free heat storage plate core

A technology without a water tank and a heat storage plate is applied in the field of solar heat collectors, which can solve the problems of poor heat preservation effect, heat loss, complex structure, etc., and achieve the effects of good heat preservation effect, pollution prevention, and increase of contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

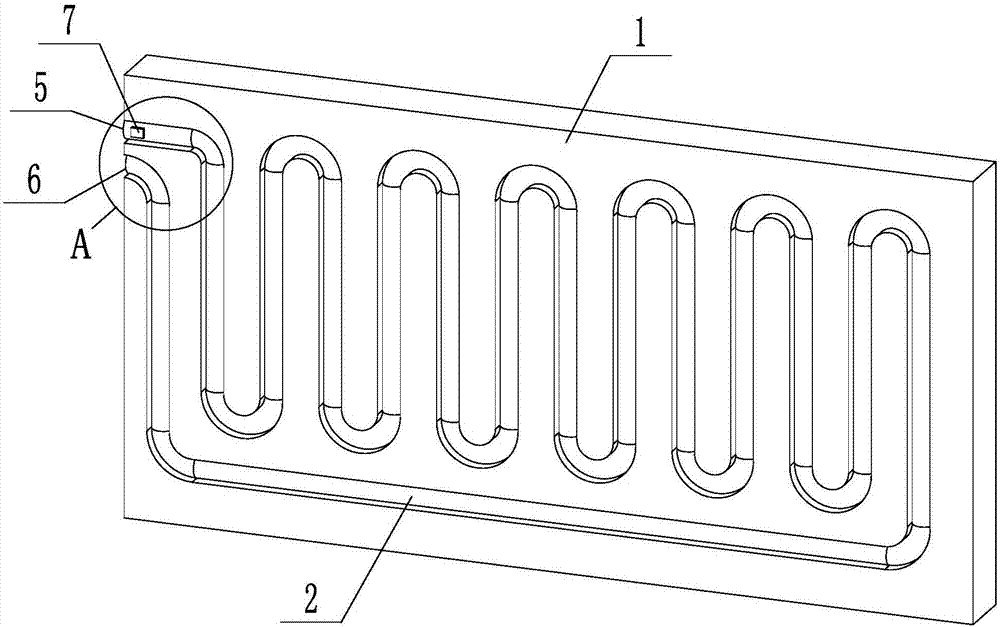

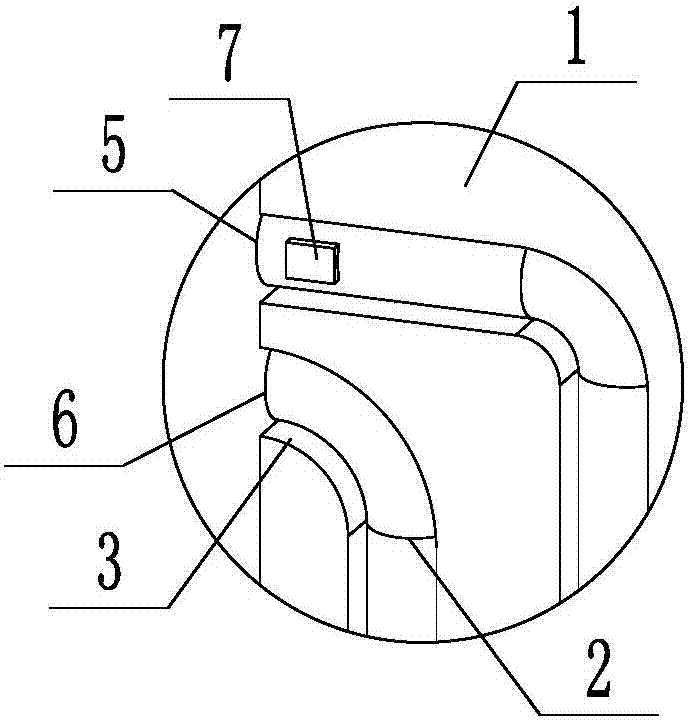

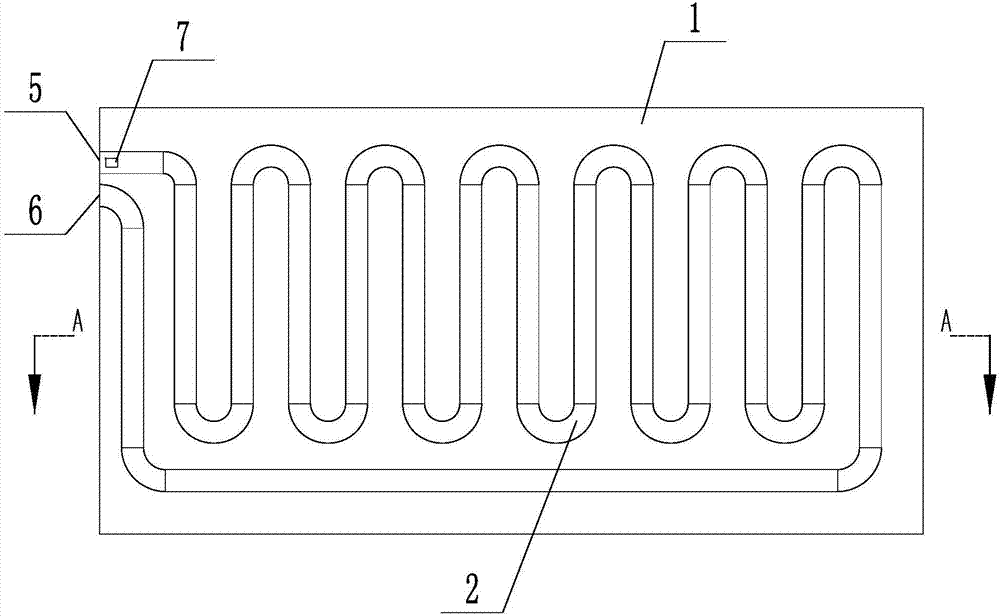

[0029] according to Figure 1 to Figure 8 As shown, a heat storage plate core without a water tank includes an energy storage tank 1 and a tankless core 2, the water tank and the core are integrated in the tankless core 2, and a groove is provided on the surface of the energy storage tank 1 Groove 3, the shape of the groove 3 corresponds to the shape of the tankless core 2, and the tankless core 2 is embedded in the surface groove 3 of the energy storage tank 1, which can better fix the tankless core 2 and prevent damage to the tankless core 2. The water tank plate core 2 increases the stability of the equipment.

[0030] The bottom end of the cross-section of the groove 3 is a semi-circular arc, and the upper end is a rectangle. The tankless plate core card is matched with the semi-circular arc at the bottom end of the groove 3, and the depth of the groove 3 is greater than the outer circle diameter of the channel of the core 2 without a water tank at the corresponding positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com