An electronic flower pillow and its working method

A technology of electronic flowers and flower pillows, applied in jacquard machines, textiles, papermaking, textiles, etc., can solve the problems of weight increase, power waste, and many parts, and achieve the effects of reducing heat generation, reducing weaving costs, and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

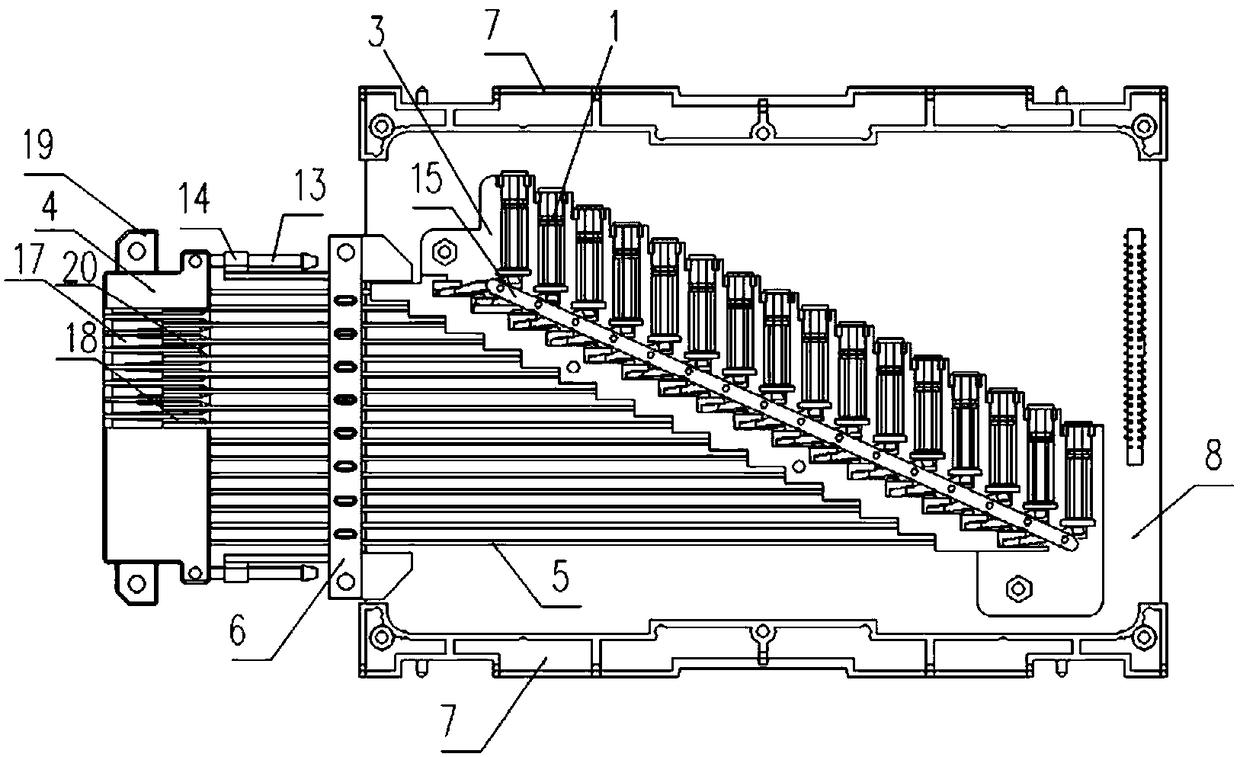

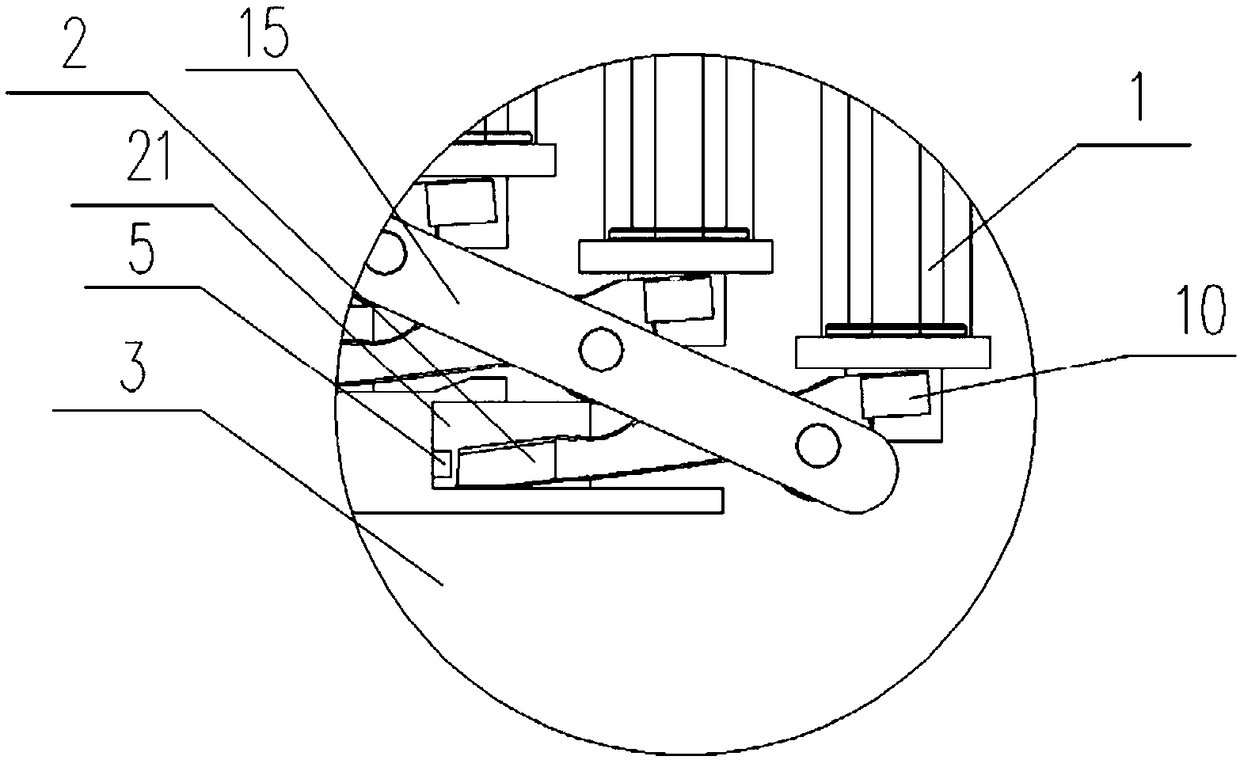

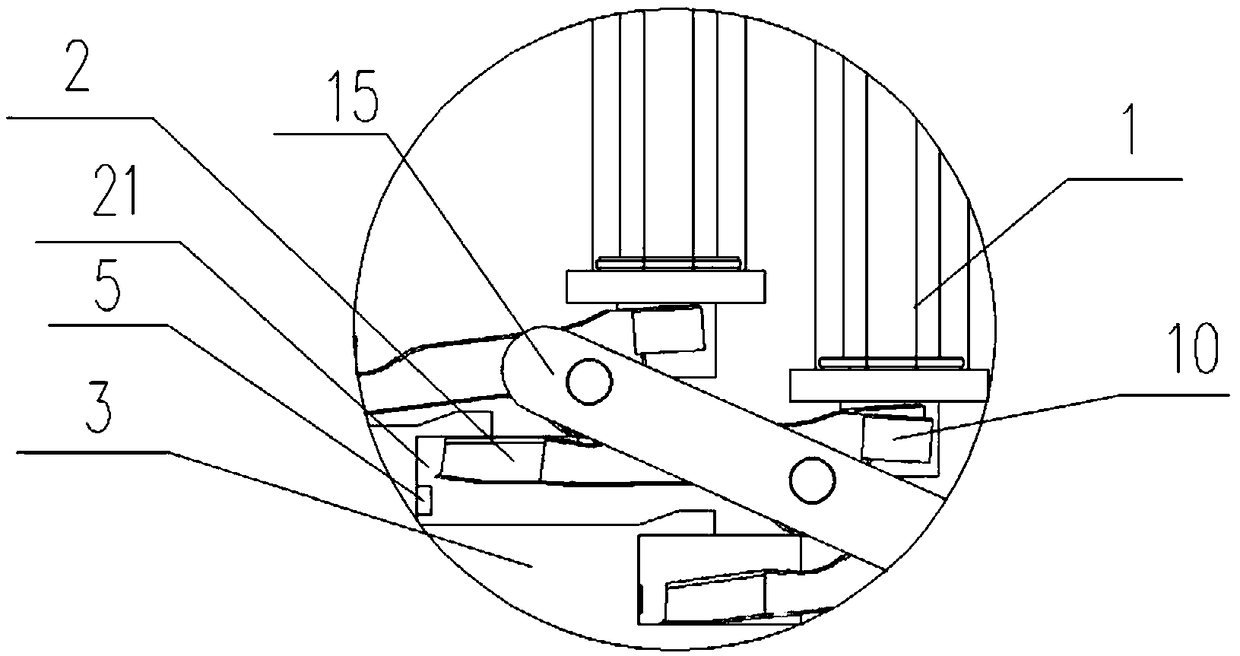

[0045] Such as Figure 1-7 As shown, an electronic flower pillow includes a computer control part, a power supply part and an electronic flower board body. The electronic flower pillow body includes a plurality of driving board assemblies 16 that are superimposed and fastened together. The driving board assembly 16 is used to control the horizontal movement of the jacquard machine Needles, the horizontal needles of the jacquard machine are arranged in a rectangular form, and one row or two rows of horizontal needles in the vertical direction are controlled by a drive board assembly 16. The drive board assembly 16 includes a circuit board 8, a data transmission interface arranged on the circuit board 8 And several execution veneers and steel needle holders 4 and steel needles 5 that cooperate with the execution veneers. One end of the steel needle 5 is connected with the steel needle fixing frame 4, and the other end of the steel needle 5 is connected with the executive board. T...

Embodiment 2

[0055] Take a 16-row mechanical jacquard machine (2560 needles) as an example. Each drive board of an electronic flower pillow has 32 pins, so 2560 / 32=80 drive boards are shared, divided into 20 pieces, a total of 4 drive board groups, put into the flower pillow case, connected to the transmission board, and distributed The board and the signal line, the power line are connected with the computer controller. The electronic flower pillow body is installed on the mechanical jacquard machine, the steel needle fixing frame is closely attached to the horizontal needle matrix, the power supply box is installed next to the jacquard machine, and the ground wire is connected. The computer controller is installed on the side of the textile machine, which is convenient for the operator to operate.

[0056] Threading needles: insert 32 steel needles into the needle holder, and place heat shrinkable tubes on the needles to prevent the needles from slipping out of the holder.

[0057] Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com