A kind of low temperature thermoforming method of three-dimensional graphene material

A molding method and graphene technology, applied in graphene, chemical instruments and methods, structural parts, etc., can solve the problems of complex preparation methods of three-dimensional graphene materials, volume shrinkage of three-dimensional graphene, and unsuitability for large-scale production, etc., to achieve The effect of low cost, friendly environment and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

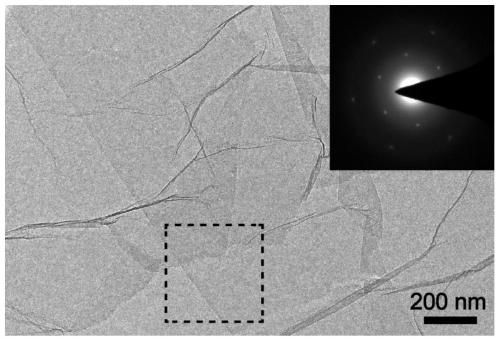

[0050] At first preferably adopt oxidation exfoliation method (Hummers method) to prepare graphene oxide aqueous solution, its specific process is as follows: get 5g natural flake graphite powder, it is mixed with the sodium nitrate of 115mL vitriol oil and 2.5g under ice-bath condition, then Slowly add 15.0g of potassium permanganate to the solution, stir for 2 hours, raise the temperature to 35 degrees, continue stirring for 2 hours, slowly add 230mL of deionized water, then further raise the temperature to 95 degrees, and maintain 30 Minutes, then add about 500mL of deionized water to the solution, adjust the temperature to room temperature, add 12.5mL of hydrogen peroxide solution, filter the solution to obtain a solid, and successively wash with dilute hydrochloric acid and deionized water to obtain oxidation graphene solution.

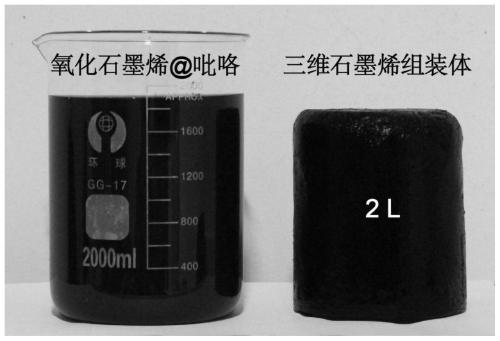

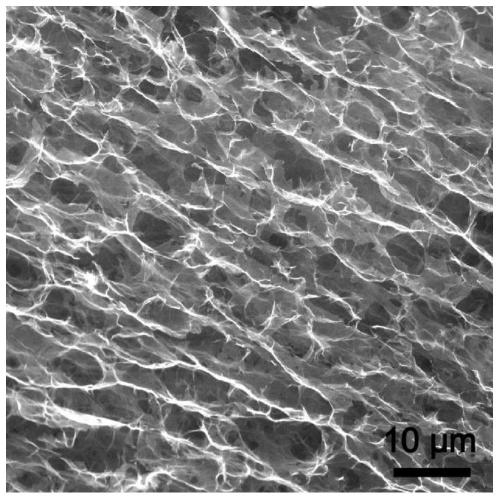

[0051] The obtained graphene oxide solution was fixed to a mass concentration of 5.0mg / mL, and 2000mL of graphene oxide solution was taken in a ...

Embodiment 2

[0054] The graphene oxide aqueous solution was prepared by the oxidation exfoliation method (Hummers method) of Example 1, and the obtained graphene oxide solution was fixed to a mass concentration of 3.0 mg / mL. Take 5mL of the solution and add 0.2mL of pyrrole monomer, mix evenly, and then pour the mixture into a petri dish. The reaction temperature of the whole system is controlled at 70°C, and the reaction time is 12 hours. After the reaction, the three-dimensional assembly film is taken out. And use deionized water to clean the surface and dialysis, the specific optical picture can be found in the attached Image 6 . Then, the film is placed in a freeze dryer for freeze-drying to obtain a three-dimensional porous graphene assembly film material, and the thickness of the film can be regulated by the volume of the injected mixed solution.

Embodiment 3

[0056] The graphene oxide aqueous solution was prepared by the oxidation exfoliation method (Hummers method) of Example 1, and the obtained graphene oxide solution was fixed to a mass concentration of 10.0 mg / mL. Take 2mL of the solution and add 0.1mL of pyrrole monomer, mix well, then inject the mixed solution into the capillary, the reaction temperature of the whole system is controlled at 75°C, and the reaction time is 2 hours. Assemble the body fiber, and wash the surface and dialyze with deionized water, the specific physical picture can be found in the attached Figure 7 . Next, the fibers are placed in a freeze dryer for freeze-drying to obtain three-dimensional porous graphene assembly fibers. The diameter of the fiber can be tuned by the diameter of the capillary.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap