PVC foamed co-extruded floor preparation process

A preparation process and flooring technology, which is applied in the field of PVC foamed co-extruded flooring preparation process, can solve the problems of low plasticity, poor moisture and water resistance, and unsatisfactory performance, and achieve strong plasticity, convenient construction, and save later maintenance and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0033] A PVC foaming co-extrusion floor preparation process, mainly including the production process of mixing materials, extrusion foaming, co-extrusion, cooling and shaping;

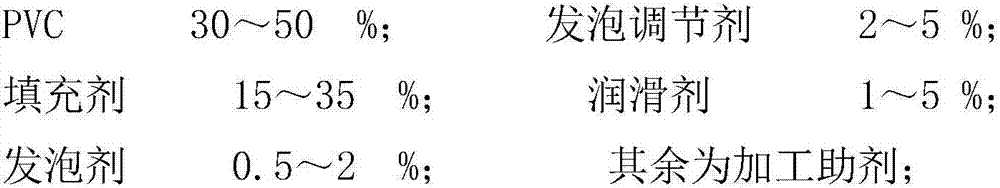

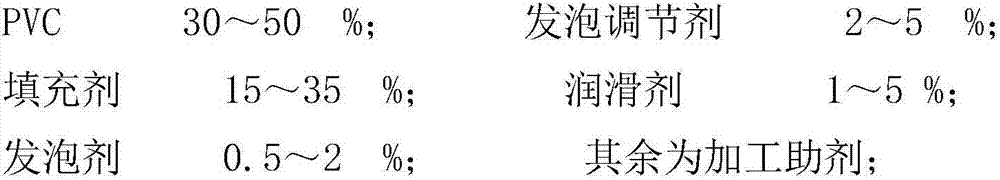

[0034] In the mixing process, the required raw material components and component quantities are:

[0035]

[0036] The sum of the amounts of the above components satisfies 100%;

[0037] During the mixing process, the materials are mixed according to the formula, and the materials are stirred at high speed by the mixer to generate heat by friction. After reaching the set process temperature of 110-115°C, they are discharged into cold mixing, and then discharged after reaching the set process temperature of 50°C;

[0038] In the process of extrusion foaming, the mixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com