Waste plastic cleaning and sorting device and technology

A waste plastic, sorting technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of non-reuse, environmental pollution, waste of resources, etc., to improve the value of reuse, reduce environmental pollution, easy to use. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

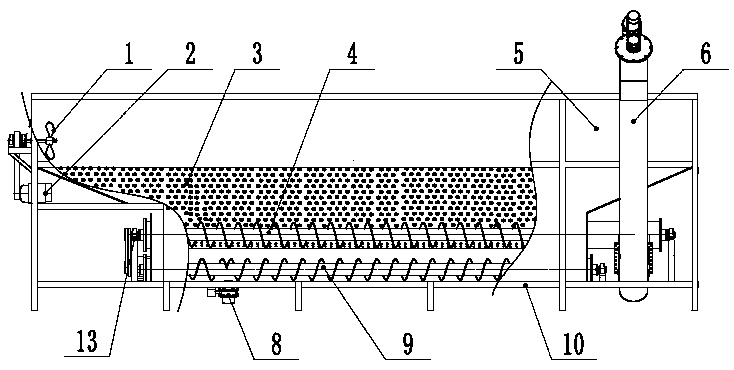

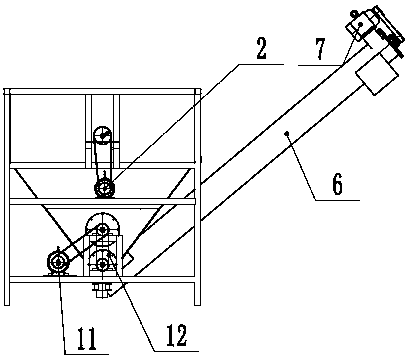

[0031] A cleaning and sorting equipment for waste plastics, which consists of three stages of cleaning and sorting equipment arranged in series; one stage of cleaning and sorting equipment includes a propeller 1, a sieve plate 3, a heavy plastic conveying screw 4, a shell 5, a heavy Plastic lifting screw machine-6, impurity timing slag discharge valve-8, impurity conveying screw machine-9 and frame-10; frame-10 and shell-5 constitute box body one, and a heavy weight is arranged in the middle of box body one Plastic conveying screw machine-4, both sides of heavy plastic conveying screw machine-4 are symmetrically equipped with sieve plate-3, and the sieve plates-3 on both sides of heavy plastic conveying screw machine-4 are arranged in a V shape, heavy plastic conveying The screw machine one 4 and the sieve plate one 3 divide the box body one into upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com