Pneumatic soft finger and soft finger control system and method

A technology of a control system and a control method, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve the problems of sensor selection and installation restrictions, and achieve the effects of good finger flexibility, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

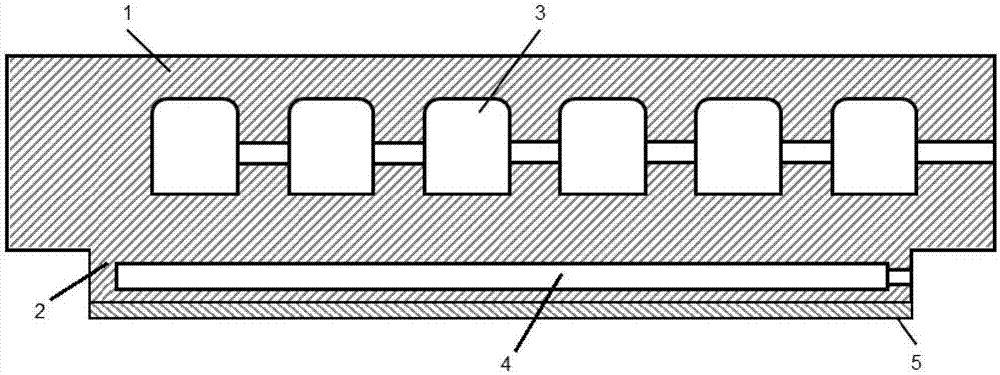

[0050] Such as figure 1 As shown, the present invention discloses a pneumatic soft finger, comprising: a driving part 1 arranged on the upper layer and a sensing part 2 arranged on the lower layer, and a Velcro 5 is stuck on the bottom surface of the sensing part 2, thereby preventing deformation of the bottom surface , to increase the effect of finger contact friction. The driving part 1 is provided with a driving air chamber 3 , and the sensing part 2 is provided with a sensing air chamber 4 . The drive part 1 and the sensing part 2 of the soft finger of the present invention are integrally manufactured by shape deposition technology. The finger has the characteristics of simple structure, high degree of integration, low cost, and good flexibility, which avoids the constraints of sensor layout and installation and its impact on finger movement in traditional sensing solutions.

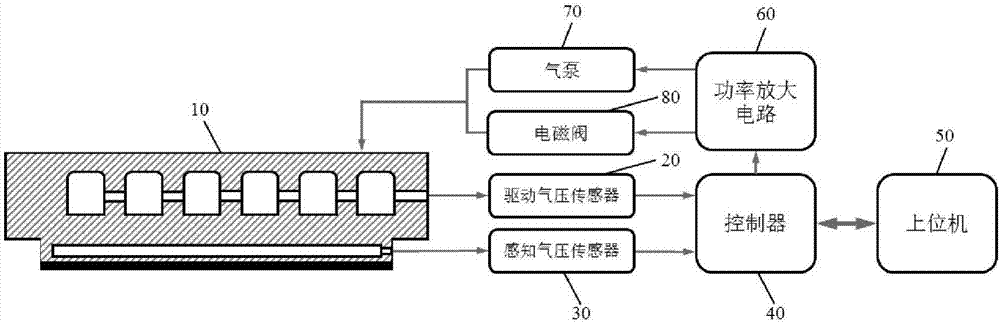

[0051] Such as figure 2 As shown, the present invention provides a pneumatic soft finger cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com