Spherical parallel mechanism

A technology of parallel connection and machine base, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc. It can solve the problems of changing the load transfer characteristics of parallel mechanisms, reducing the load transfer efficiency of moving platforms, and affecting the working performance of moving platforms, so as to improve the load capacity. and motion accuracy, improve work performance, and increase stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

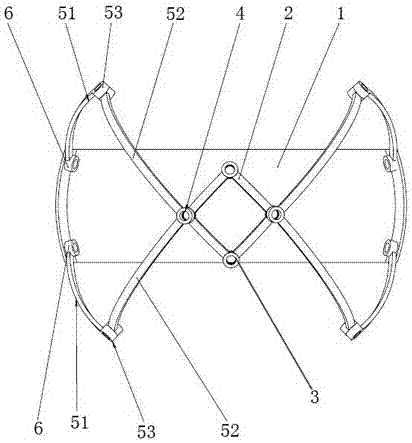

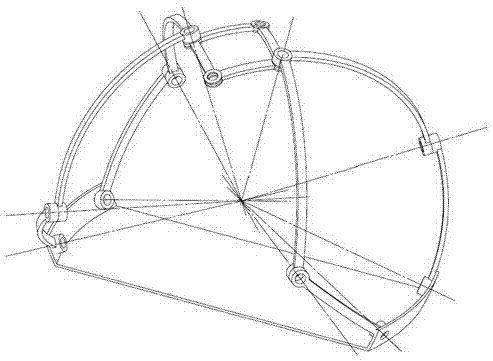

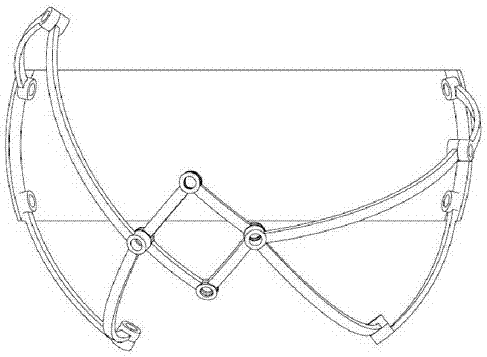

[0036] as attached figure 1 and 2 As shown, the present invention discloses a spherical parallel mechanism, including a machine base 1 and a moving platform 2, at least two sets of kinematic branch chains are arranged between the machine base 1 and the moving platform 2, and one set of kinematic branch chains includes two Active connecting rod 51 and two driven connecting rods 52; in the same group of kinematic branch chains, two active connecting rods 51 are rotationally connected with the base 1 through the rotating pair 6 of the base respectively, and one active connecting rod 51 is correspondingly passed through a connecting rod The rotary pair 53 is connected in rotation with a driven link 52, and the two driven links are connected in rotation through the output rotary pair 4. The connection po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com