Variable-diameter high-seal pressure-shooting device

A high-sealing and variable technology, applied in the field of die-casting machine feeding equipment, can solve problems such as punch lubrication, reduce frictional resistance, avoid punch sticking, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

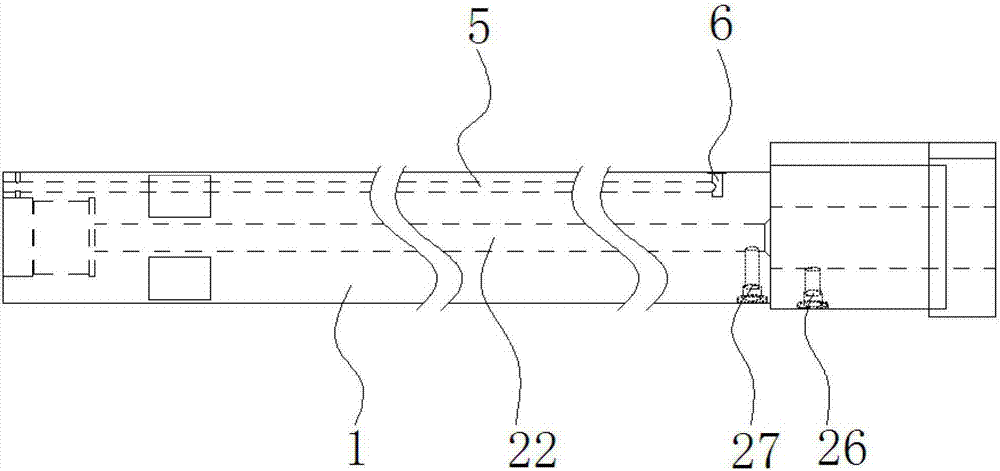

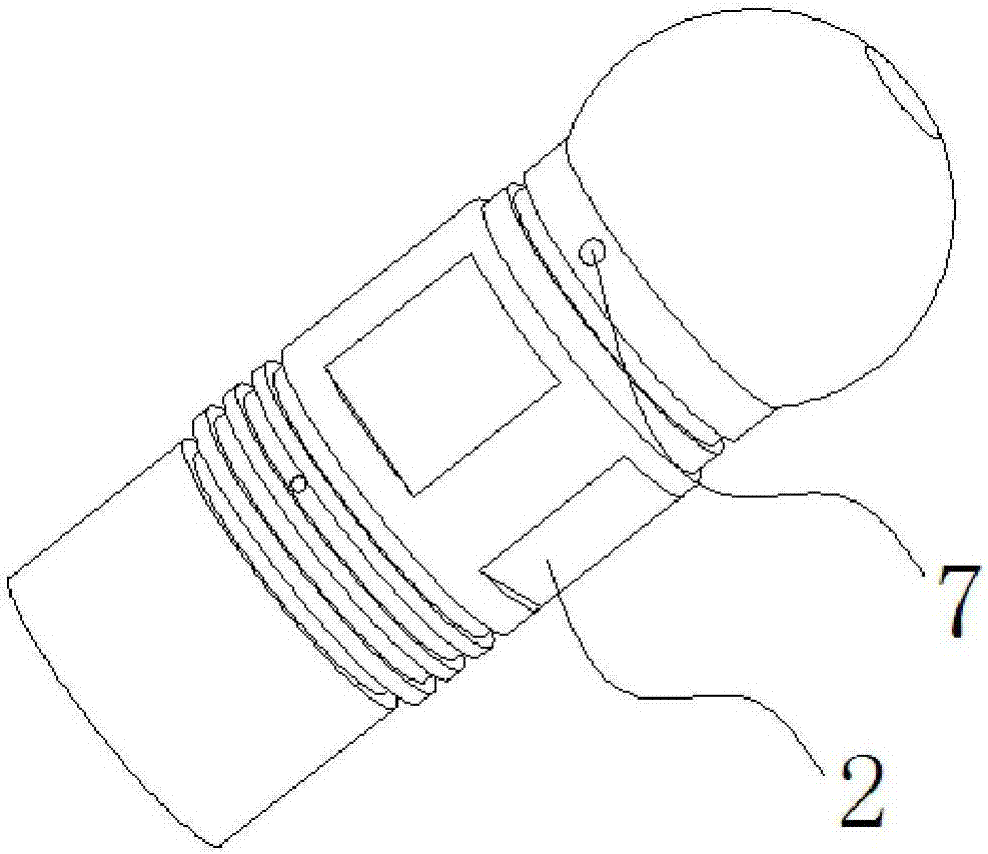

[0039] Such as figure 1 As shown, the present invention includes a plunger 1, a ball joint 2, a cooling water delivery assembly 3 and a punch assembly 4, the ball end of the ball joint 2 is installed in one end of the punch assembly 4, The other end is installed in one end of the injection rod 1 . Such as image 3 As shown, the ball joint 2 enables the punch assembly 4 to have a certain amount of rotation, avoiding the problem of jamming the punch 4-3 caused by the installation deviation of the punch assembly 4 . Specifically, one end of the injection rod 1 is provided with a corresponding installation groove, and the other end of the connector 2 is arranged in the installation groove; as figure 2 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com