Annular strain gauge for hole drilling method

A technology of strain gauge and drilling method, which is applied in the field of ring strain gauge, can solve the problems of increasing test difficulty and error by drilling method, and achieve the effect of reducing the difficulty of patching and improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

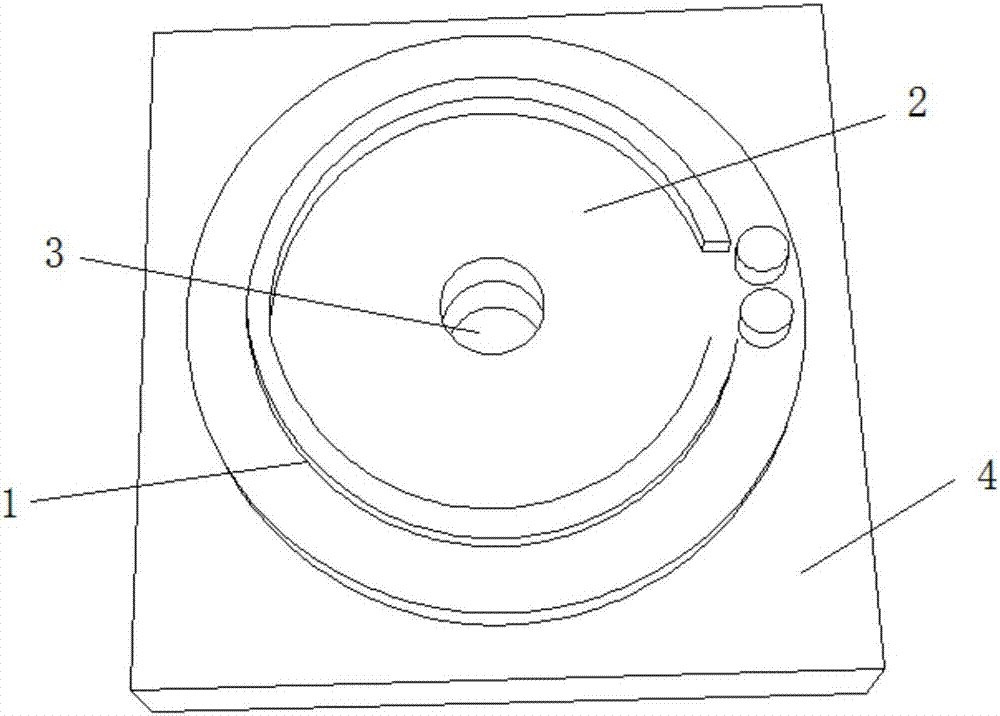

[0015] Such as figure 2 As shown, a ring-type strain gauge used for the drilling method includes a resistance wire 1 and an insulating base 2. The resistance wire 1 is arranged on the insulating base 2 in a ring-wound manner. The center of the resistance wire 1 is reserved for Drill marks.

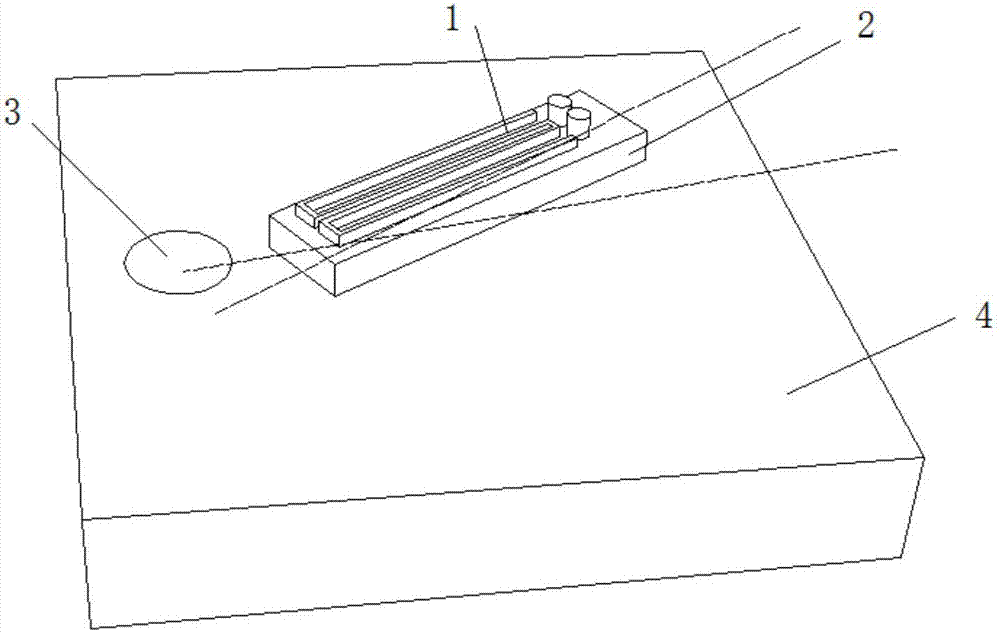

[0016] The present invention is a ring-type strain gauge used in the drilling method. The working principle is: the ring-type strain gauge is pasted on the base material 4, and the insulating base 2 made of epoxy phenolic and other materials is used as the base material 4 and the resistance wire 1, drill a small hole 3 at the drilling mark reserved at the center of the resistance wire 1 during the test for strain relief. To sum up, the present invention is free to mount, can effectively reduce the testing difficulty of the drilling method using traditional strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com