Non-contact underwater full-field strain measurement method

A strain measurement, non-contact technology, used in measurement devices, instruments, optical devices, etc., can solve the problem of inability to measure underwater full-field strain, and achieve the effect of convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

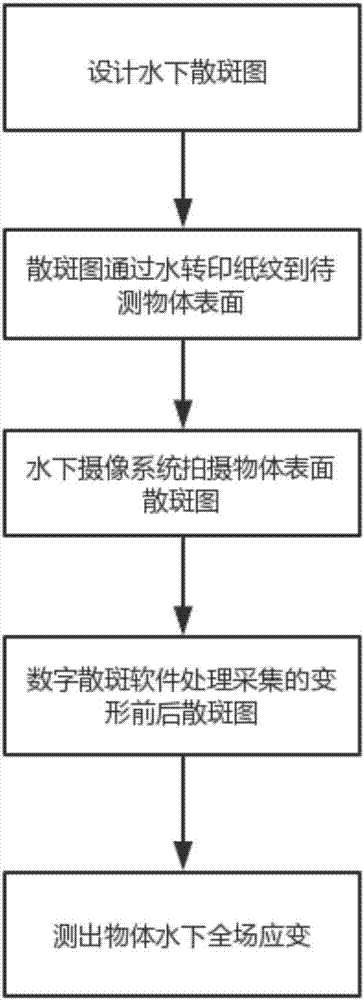

[0019] combine figure 1 , a non-contact underwater full-field strain measurement method is characterized in that the method steps are as follows:

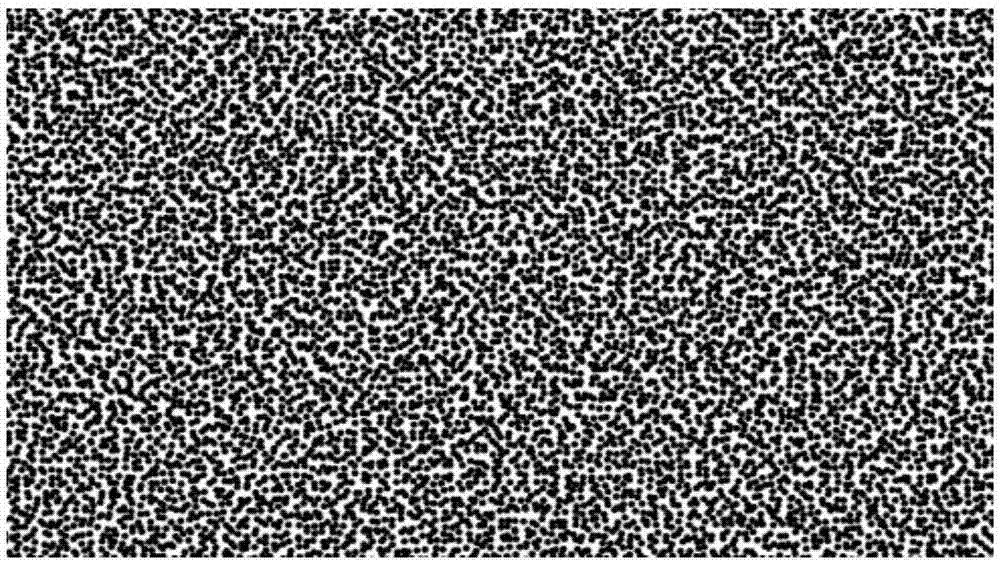

[0020] Step 1. Print the designed speckle pattern on the water transfer printing paper pattern, and pass the water transfer printing paper pattern to the surface of the object to be tested;

[0021] Step 2, taking speckle images of underwater objects before and after deformation through the underwater camera system;

[0022] Step 3. The computer processes the speckle image through digital speckle software to obtain a full-field deformation map of the underwater object.

[0023] combine figure 2 , the underwater camera system in step 2 includes a binocular camera 1, a camera housing 4, 2N photographic lights 3, two pieces of optical glass 2, two vertical arms 5 and two rolling bearings 6, wherein N≥3, The fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com