Curtain wall node structure made from low-radiation film-mounted hollow glass instead of laminated hollow glass

A technology of laminated hollow glass and node structure, which is applied in the direction of parallel glass structures, walls, building components, etc., can solve the problems of increasing the size and wall thickness of aluminum alloy profiles, increasing the cost of glass curtain walls, and increasing the weight of glass curtain wall units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

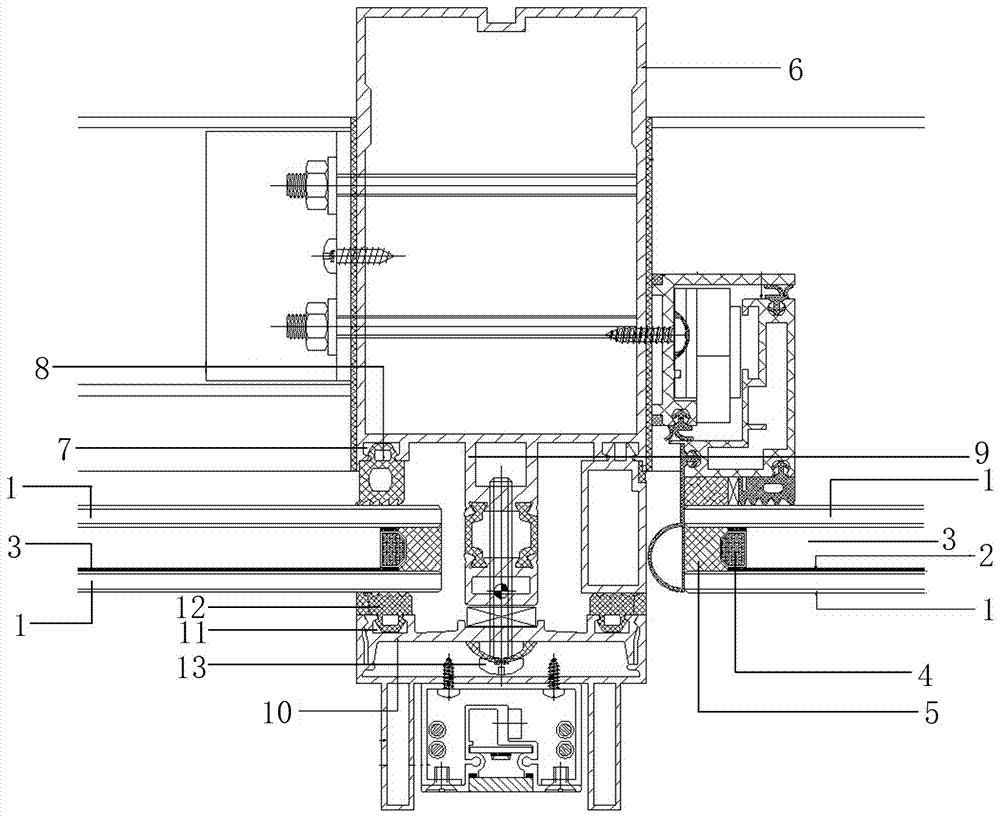

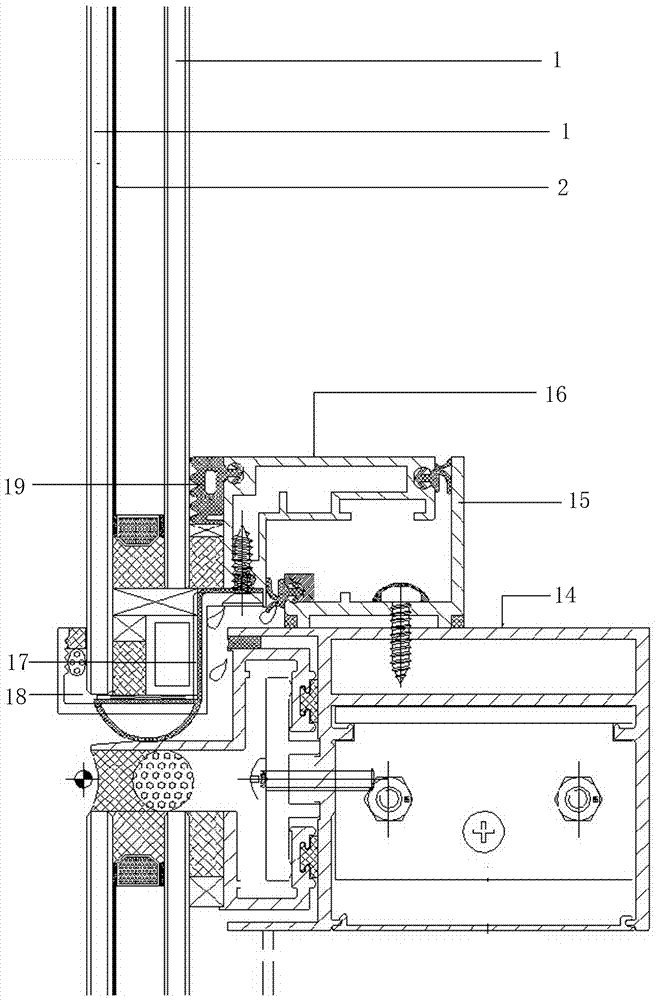

[0030] The present invention will be further described below with reference to the accompanying drawings.

[0031] The invention discloses a low-emissivity film-attached hollow glass curtain wall node structure that replaces laminated insulating glass. It consists of semi-tempered ultra-clear glass 1, wherein the inner surface of the semi-tempered ultra-clear glass 1 on the outside is covered with a layer of low-radiation anti-riot film 2, and a hollow interlayer 3 is formed between two semi-tempered ultra-clear glass 1, and the two semi-tempered ultra-clear glass 1 An aluminum profile frame 4 is arranged between the edges of the white glass 1, and sealant 5 is filled around the outer edge of the aluminum profile frame 4. The curtain wall node structure also includes longitudinally distributed aluminum alloy columns 6, and the outer edges of the aluminum alloy columns 6 are along the aluminum The alloy column 6 is provided with an inner rubber strip fixing slot 7, one side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com