Method for fermenting alcohol by mixing corn mash and soybean aqueous enzymatic hydrolysate

A technology for mixing fermentation and hydrolyzate, applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of complex production process and high cost, improve alcohol yield, solve high cost, and solve environmental pollution. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

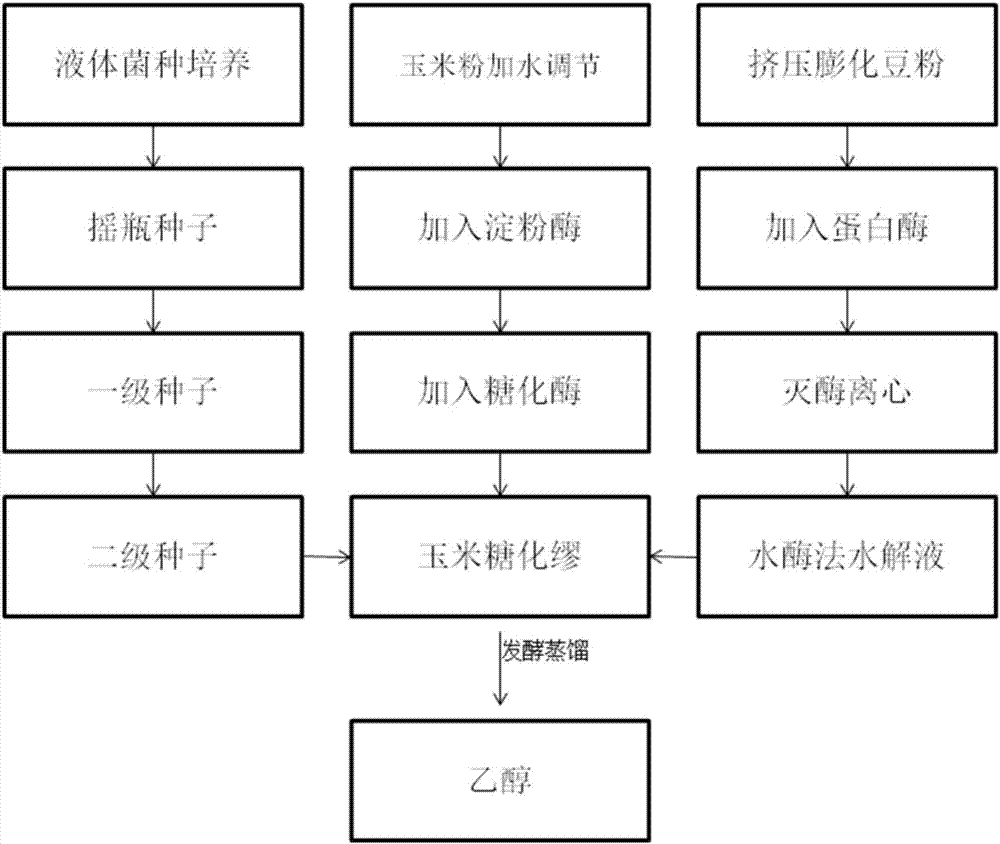

Image

Examples

Embodiment 1

[0020] (1) The preparation process of corn saccharification used in this experiment is as follows: corn flour and water are mixed at a ratio of 1:4 to make a mixture, and then stand for 30 minutes after mixing. Add amylase (10u / g starch) based on 70% starch content of corn flour, raise the temperature to 90°C, and keep it warm for 30min. That is saccharification;

[0021] (2) The water enzymatic hydrolyzate extraction process used in this experiment is: mix puffed soybean powder and deionized water at a ratio of 1:5, add Alcalase alkaline protease, enzymatically hydrolyze at 55°C for 3 hours, then inactivate the enzyme and centrifuge to remove soybean oil , emulsion and the insoluble residue in the lower layer to obtain the hydrolyzate;

[0022] (3) Trichoderma pseudokonii was selected as the fermentation strain, and under sterile conditions, it was amplified and cultivated step by step on a test tube slope, a shaker flask, a first-level seed tank, and a second-level seed tan...

Embodiment 2

[0025] (1) The preparation process of corn saccharification used in this experiment is as follows: corn flour and water are mixed at a ratio of 1:4 to make a mixture, and then stand for 30 minutes after mixing. Add amylase (10u / g starch) based on 70% starch content of corn flour, raise the temperature to 90°C, and keep it warm for 30min. That is saccharification;

[0026] (2) The water enzymatic hydrolyzate extraction process used in this experiment is: mix puffed soybean powder and deionized water at a ratio of 1:5, add Alcalase alkaline protease, enzymatically hydrolyze at 55°C for 3 hours, then inactivate the enzyme and centrifuge to remove soybean oil , emulsion and the insoluble residue in the lower layer to obtain the hydrolyzate;

[0027] (3) Select the cellulase-producing bacterium Pseudomonas konshii as the fermentation strain. Under sterile conditions, the OD value of the number of bacteria is obtained by step-by-step amplification and cultivation of the test tube i...

Embodiment 3

[0030] (1) The preparation process of corn saccharification used in this experiment is as follows: corn flour and water are mixed at a ratio of 1:4 to make a mixture, and then stand for 30 minutes after mixing. Add amylase (10u / g starch) based on 70% starch content of corn flour, raise the temperature to 90°C, and keep it warm for 30min. That is saccharification;

[0031] (2) The water enzymatic hydrolyzate extraction process used in this experiment is: mix puffed soybean powder and deionized water at a ratio of 1:5, add Alcalase alkaline protease, enzymatically hydrolyze at 55°C for 3 hours, then inactivate the enzyme and centrifuge to remove soybean oil , emulsion and the insoluble residue in the lower layer to obtain the hydrolyzate;

[0032] (3) Select the cellulase-producing bacterium Pseudomonas konshii as the fermentation strain. Under sterile conditions, the OD value of the number of bacteria is obtained through the step-by-step amplification culture of the test tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com