Wet-flue-gas desulfurization washing water treatment system and method of ships

A technology of wet flue gas desulfurization and washing water, which is applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. Meet the restriction requirements, blockage of resin adsorption column and other problems, achieve high removal rate of suspended solids, stable removal effect, and reduce the effect of adsorption load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

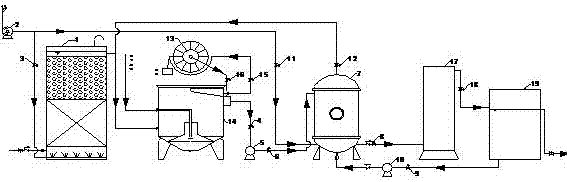

[0053] This embodiment provides a ship wet flue gas desulfurization washing water treatment system, such as figure 1 As shown, it includes: an iron-carbon micro-electrolysis flocculation reactor 1, a vertical flow air flotation tank 14, a first sand filter 7, an adsorbent adsorber 17 and a clarified water tank 19.

[0054] The bottom of the iron-carbon micro-electrolysis flocculation reactor 1 is provided with a first water inlet and an aeration inlet, and the top is provided with a first water outlet. The washing water enters the iron-carbon micro-electrolysis flocculation reactor 1 through the first water inlet, and the aeration enters The air port is connected to the air outlet of the first blower 2, and the iron-carbon micro-electrolysis flocculation reactor 1 is used for aeration, micro-electrolysis oxidation reaction in the iron-carbon area and flocculation reaction in the micro-vortex flocculation area sequentially from bottom to top. The washing water first enters the ...

Embodiment 2

[0072] This embodiment provides a ship wet flue gas desulfurization washing water treatment method, which is suitable for the ship wet flue gas desulfurization washing water treatment system in embodiment 1, including the following steps:

[0073] S1. The washing water enters the iron-carbon micro-electrolysis flocculation reactor 1 through the first water inlet, and the aeration inlet is fed into the air, and the aeration device is used for continuous and uniform aeration;

[0074] S2. The iron-carbon zone and the micro-vortex flocculation zone of the iron-carbon micro-electrolysis flocculation reactor 1 perform micro-electrolysis oxidation reaction and flocculation reaction on the flowing water in sequence, and then the water flows out from the first water outlet and passes through the vertical flow air flotation tank 14 The bottom water inlet flows into the vertical flow air flotation tank 14;

[0075] S3. The vertical flow air flotation tank 14 uses low-temperature seawate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com