Grain scrapping and sucking integrated sunning ground grain collecting vehicle and operation method thereof

An integrated, grain collection vehicle technology, applied in loading/unloading, conveyor, transportation and packaging, etc., can solve problems such as lack of grain, achieve the effect of reducing the erection height, improving flexibility, and avoiding the interference of line of sight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

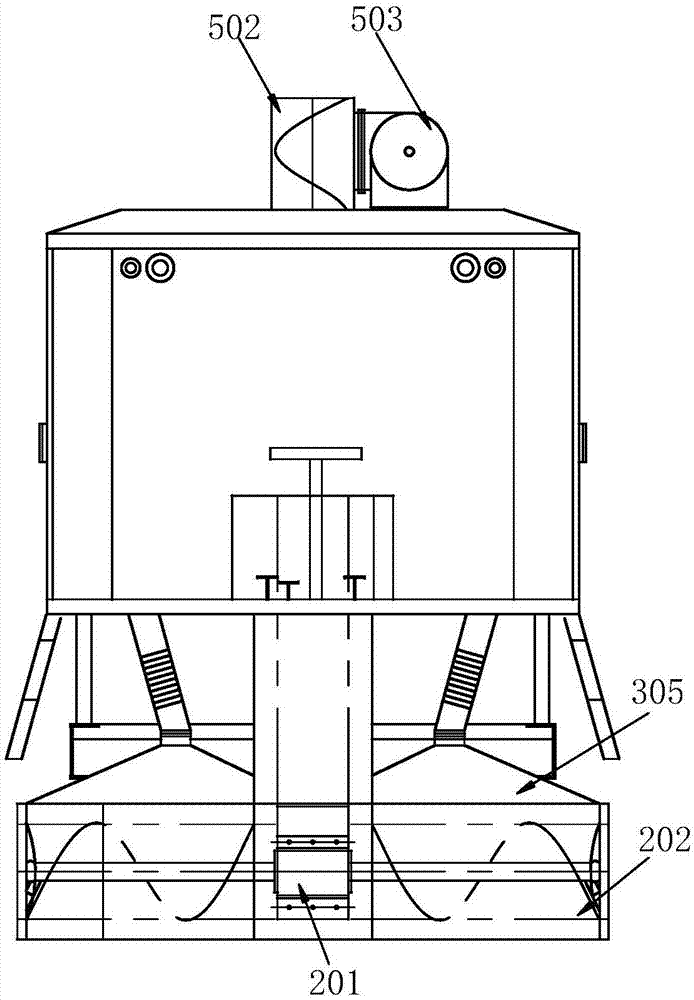

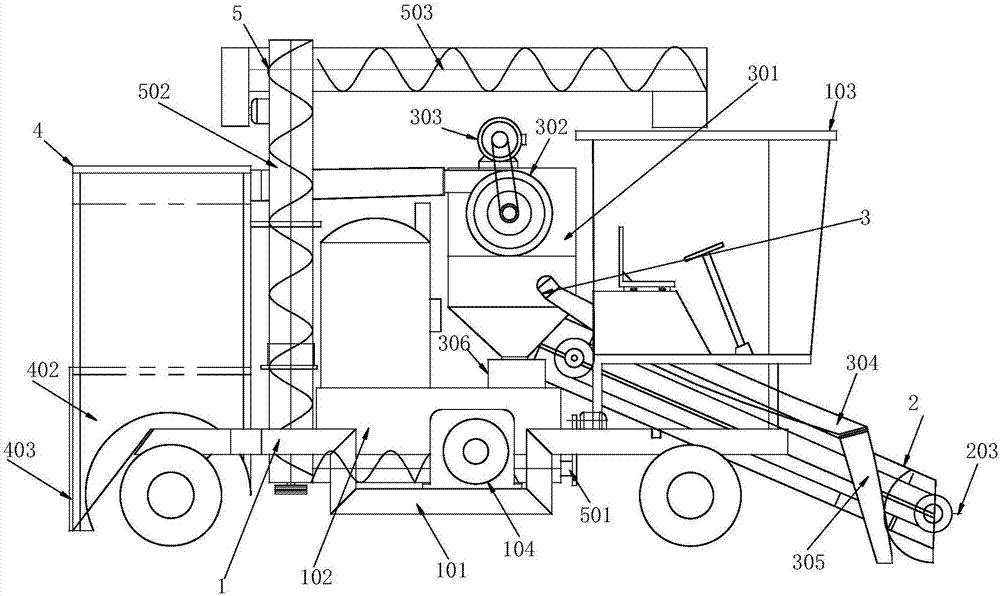

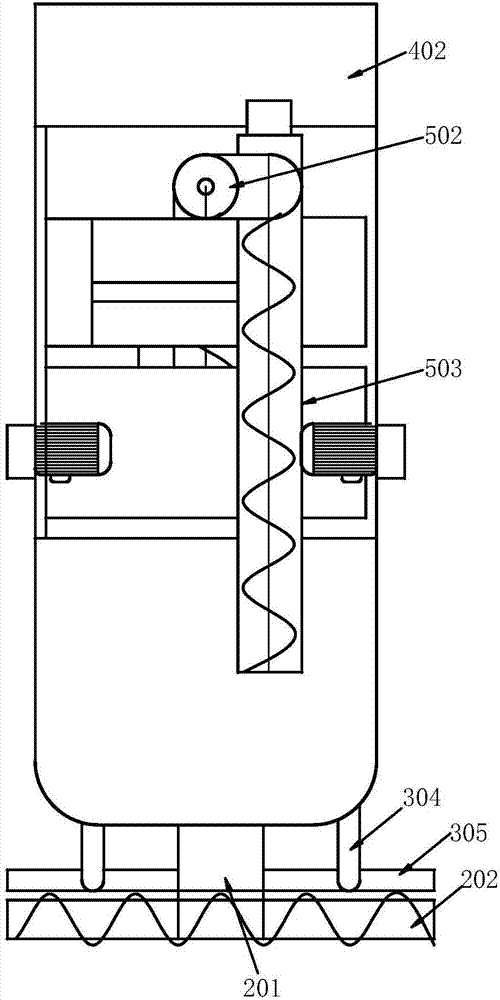

[0057] Such as Figure 1 to Figure 11 As shown in the figure, there is a grain harvesting vehicle integrated with grain picking and absorbing. The chassis 1 of the grain harvesting vehicle is equipped with a grain picking system 2 for picking up grain, and a system for cleaning up the remaining grain in cooperation with the grain picking system 2. The grain suction system 3, the dust removal system 4 for processing the dust generated by the grain suction system 3, and the grain pushing mechanism 5 for transferring grain from the grain collection vehicle to the outside.

[0058] In the prior art, the grain collection vehicle is small in size, and the grain collected by the grain collection vehicle is collected in bags. The bags are placed at the rear end of the grain collection vehicle. After a bag is full, the bag is replaced to continue collecting. In the process of collecting grain, the process of collecting grain is uninterrupted, causing the grain to spill during the proce...

Embodiment 2

[0078] On the basis of the basic technical solution of Embodiment 1, the front, left and right sides of the cab are all sealed with transparent materials to ensure a safe and independent operating environment for the driver.

Embodiment 3

[0080] On the basis of the basic technical scheme of embodiment 1, the lower edge of the dodge door 403 coincides with the lower edge of the rear side of the dust removal box 402. The lower edge of the rear side of 402 overlaps, dust will not accumulate in the dust removal box 402, the cleaning is more thorough, and the ash discharge efficiency is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com