Cutting machine for producing chemical fiber

A cutting machine and chemical fiber technology, applied in the direction of dryers, metal processing, lighting and heating equipment, etc., can solve the problems of affecting cutting quality and inconvenient adjustment of cutting length, and achieve the effect of easy adjustment and convenient cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

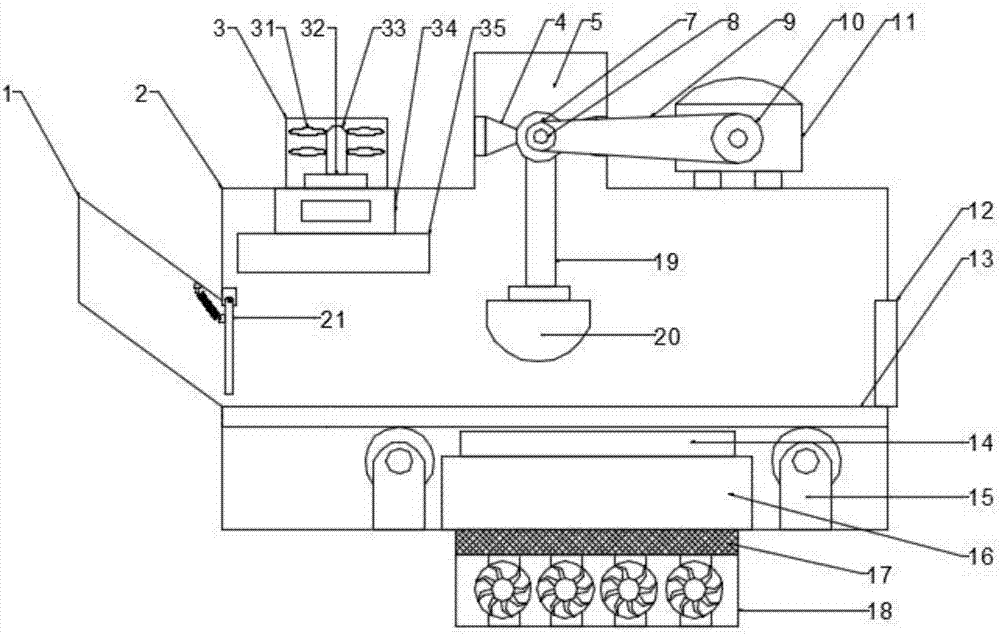

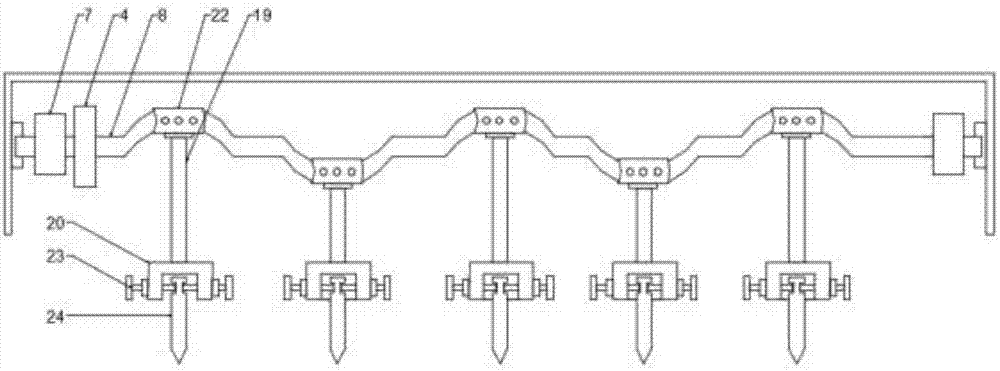

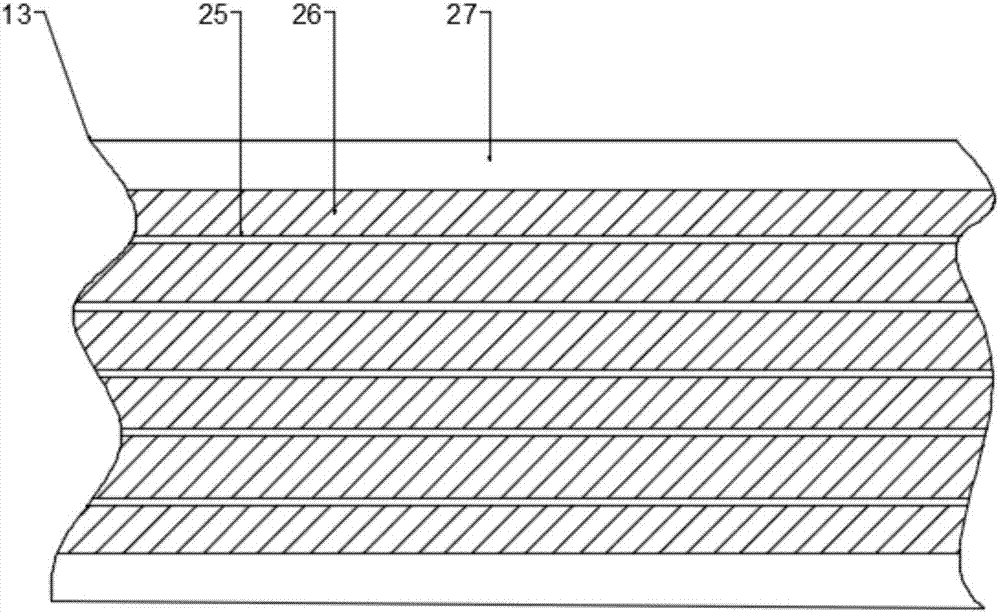

[0020] see Figure 1-3 , a cutting machine for producing chemical fibers, comprising a cutting machine 2, the left side of the cutting machine 2 is provided with an evolution fiber tube 1, a buffer device 21 is provided at the connection between the evolution fiber tube 1 and the cutting machine 2, and a buffer device 21 is provided on the buffer device 21. There are a fixed plate, a rotating plate and a limit spring. The top of the cutting machine 2 is provided with a drying device 3. The inside of the drying device 3 is provided with a motor 32. The upper end of the motor 32 is fixed with a rotating shaft 33, and the surrounding area of the rotating shaft 33 is provided with impellers 31 distributed in arrays. , motor 32 lower end cutting machine 2 is provided with heater 34 lower end is provided with air outlet plate 35, is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com