Shift register and driving method, grid driving circuit and display device thereof

A technology of shift register and reset signal, applied in the field of gate drive circuit, display device, and shift register, can solve the problems of increased process difficulty, increased production cost, complicated connection structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

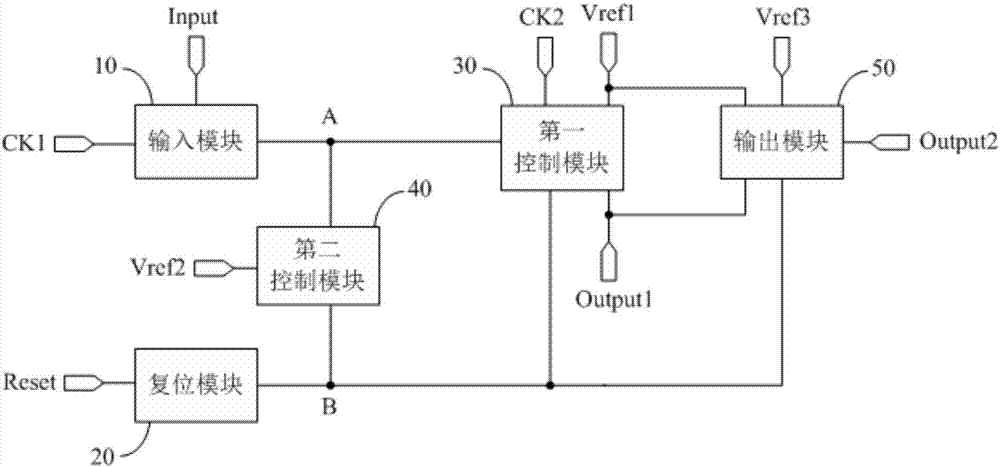

Method used

Image

Examples

Embodiment 1

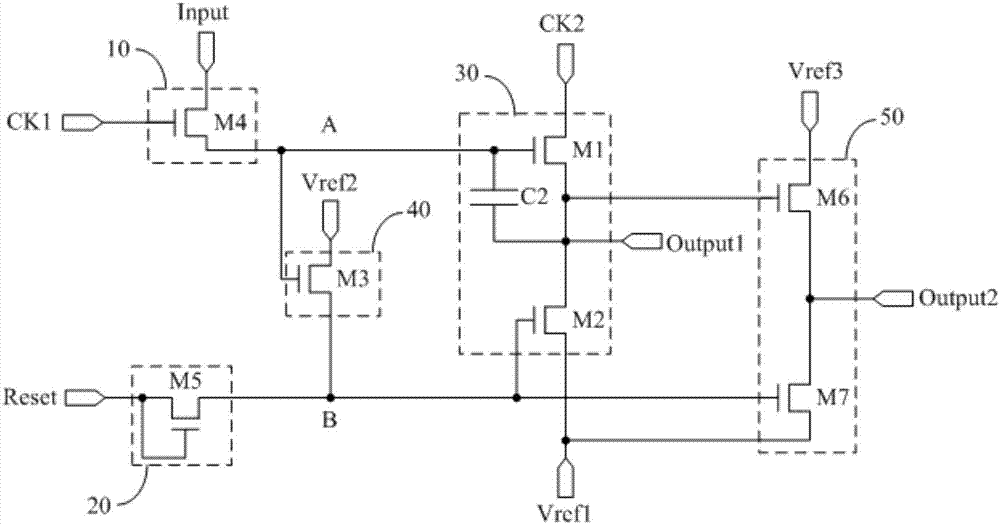

[0093] by Figure 4a The structure of the shift register shown is taken as an example to describe its working process, and the corresponding input and output timing diagrams are shown in Figure 5a As shown, specifically, the main selection such as Figure 5a There are three stages T1, T2 and T3 in the shown input and output timing diagram, and there is an inversion stage T0 in the blanking time, and the duration of the inversion stage T0 is the preset duration. Wherein, the potential of the first reference signal terminal Vref1 and the potential of the second reference signal terminal Vref2 are both low potential, and the potential of the third reference signal terminal Vref3 is high potential; The preset duration in the time Blank time is low potential, and the rest of the time is high potential.

[0094] In the T1 stage, Input=1, Reset=0, CS=1, CK1=1, CK2=0.

[0095] Since CK1=1, the fourth switching transistor M4 is turned on and provides the high potential signal of th...

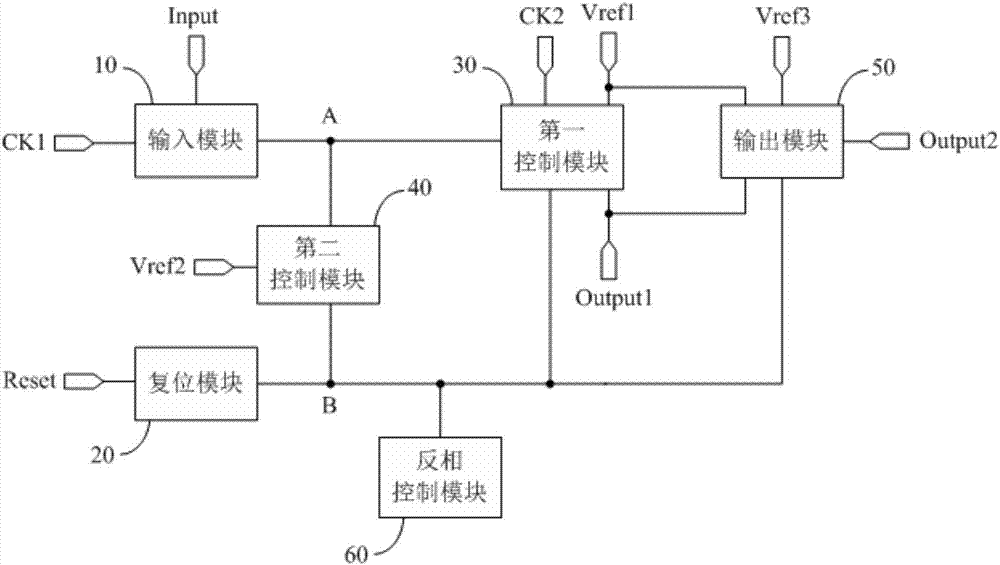

Embodiment 2

[0110] by Figure 4b The structure of the shift register shown is taken as an example to describe its working process, and the corresponding input and output timing diagrams are shown in Figure 5b As shown, specifically, the main selection such as Figure 5b There are three stages T1, T2 and T3 in the shown input and output timing diagram, and there is an inversion stage T0 in the blanking time, and the duration of the inversion stage T0 is the preset duration. Wherein, the potential of the first reference signal terminal Vref1 and the potential of the second reference signal terminal Vref2 are both high potential, and the potential of the third reference signal terminal Vref3 is low potential; The preset time in the time Blank time is high potential, and the rest of the time is low potential.

[0111] In the T1 stage, Input=0, Reset=1, CS=0, CK1=0, CK2=1.

[0112] Since CK1=0, the fourth switching transistor M4 is turned on and provides the low potential signal of the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com