A kind of fireworks charge production line

A production line and charging technology, used in fireworks, offensive equipment, weapon types, etc., can solve the problems of product quality, personnel safety production speed cannot be guaranteed, restricting the development of fireworks manufacturing industry, complex fireworks production process and other problems, to reduce labor The effect of cost, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

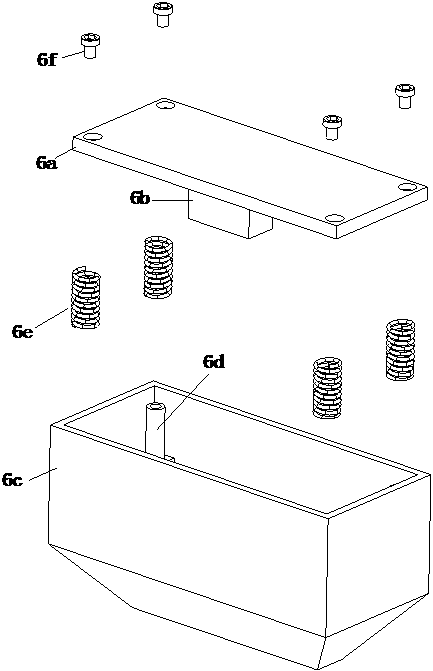

[0032] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments of the specification:

[0033] Reference Figure 1 to Figure 11 A firework charge production line shown includes a feeding mechanism, a proportioning mechanism, a filling mechanism, a raw material transmission mechanism, and a cake crust transmission mechanism. The feeding mechanism includes a plurality of agitating cylinders 1a arranged in parallel, and the proportioning mechanism It is connected with a plurality of mixing cylinders 1a through a raw material transmission mechanism, and the raw material transmission mechanism is also connected with a filling mechanism. The filling mechanism is installed directly above the crust transmission mechanism, and the crust 7 moves on the crust transmission mechanism. The filling agency charges it.

[0034] Preferably, the present invention further includes a plurality of explosion-proof chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com