Vegetable cutting device

A vegetable cutter and knife technology, which is applied in metal processing and other directions, can solve the problems of cutting fingers, uneven slice thickness, unsafety, etc., and achieve good use effect, improve vegetable cutting efficiency, and uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

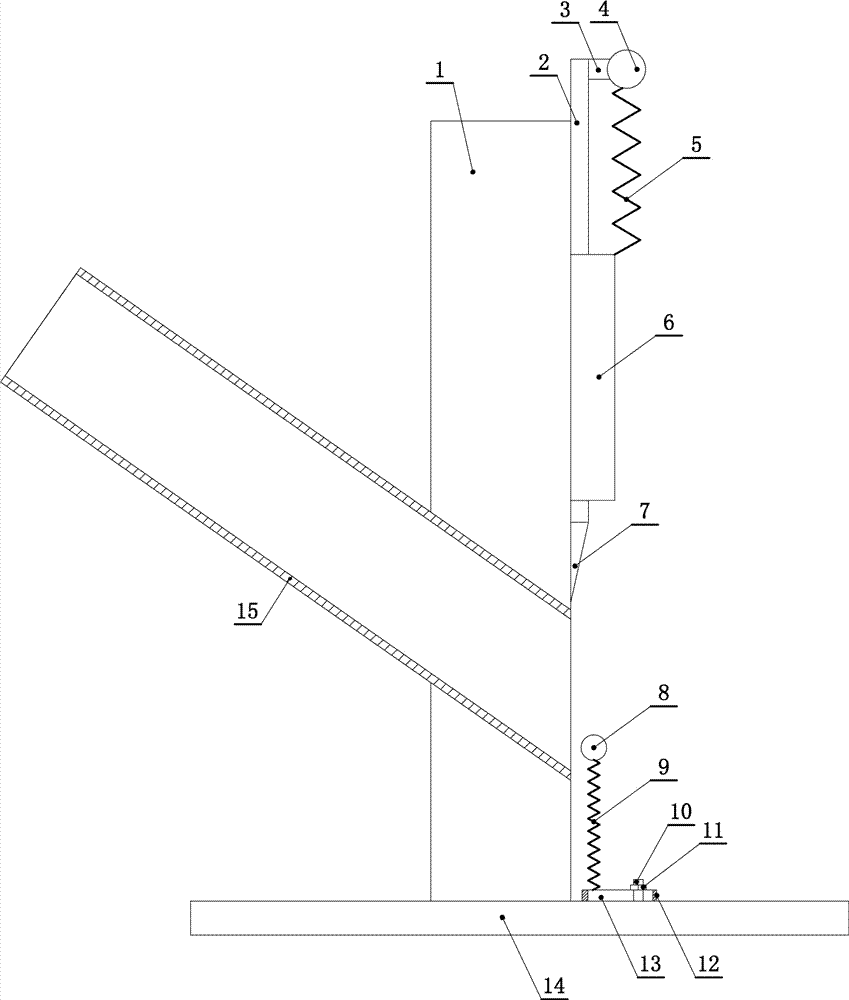

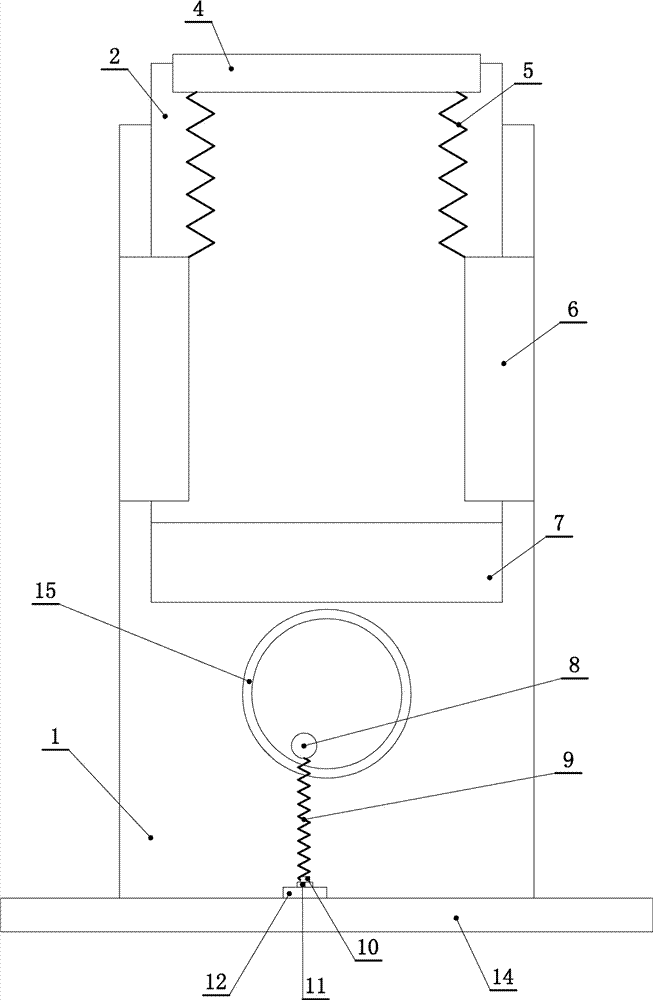

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0015] like figure 1 and figure 2 As shown, a vegetable cutter includes a vertical plate (1). There are left and right transparent perforations on the vertical plate (1). A guide cylinder (15) is fixedly connected to the perforation, and the left end of the guide cylinder (15) is inclined upward. , the right port of the guide cylinder (15) does not exceed the right side of the vertical plate (1); the front and rear of the right side of the vertical plate (1) are fixedly connected with splints (6), and the front and rear splints (6) are up and down A cutter (2) is movably connected, and the cutter (2) is set close to the right side of the vertical plate (1). 6) are fixedly connected with the lifting spring (5) ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com