Highly anti-clogging buried pressure compensation drip irrigation irrigator

A pressure compensation and irrigation technology, applied in watering devices, climate change adaptation, gardening, etc., can solve problems such as inability to guarantee flow uniformity and consistency, clogging of irrigation devices, etc., to avoid sediment and root invasion, avoid The effect of suction clogging, overcoming unevenness and inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

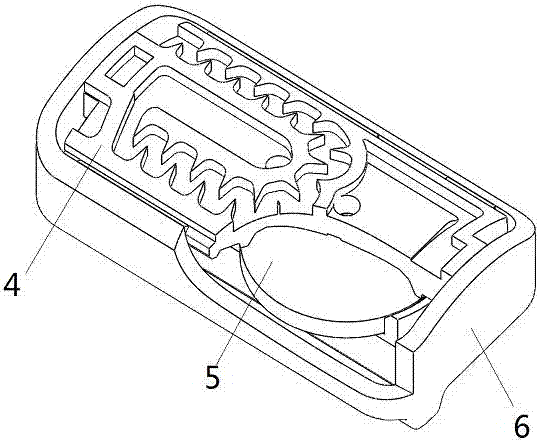

[0024] Such as Figure 1~7 As shown, a highly anti-clogging underground pressure-compensated drip irrigation emitter includes an inlaid pressure-compensated dripper 2 bonded to the inner wall of a PE hose 1 by hot-melting. The PE hose 1 is provided with a water outlet 3 along a narrow slit perpendicular to the cross section of the pipe. The built-in pressure compensation dripper 2 includes an upper cover 4 and a lower casing 6 connected together and an elastic membrane 5 installed between the upper cover 4 and the lower casing 6 . The elastic diaphragm 5 refers to a disc made of silicon rubber with a diameter of 8.8 mm and a thickness of 1 mm.

[0025] The front of the upper cover sheet 4 is provided with a cylindrical upper cover sheet welding surface 13, and the flanks on both sides are respectively provided with an assembly card platform 14, and the back is flat; The main channel 8 and the water outlet buffer chamber 11; one end of the main channel 8 is provided with a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com