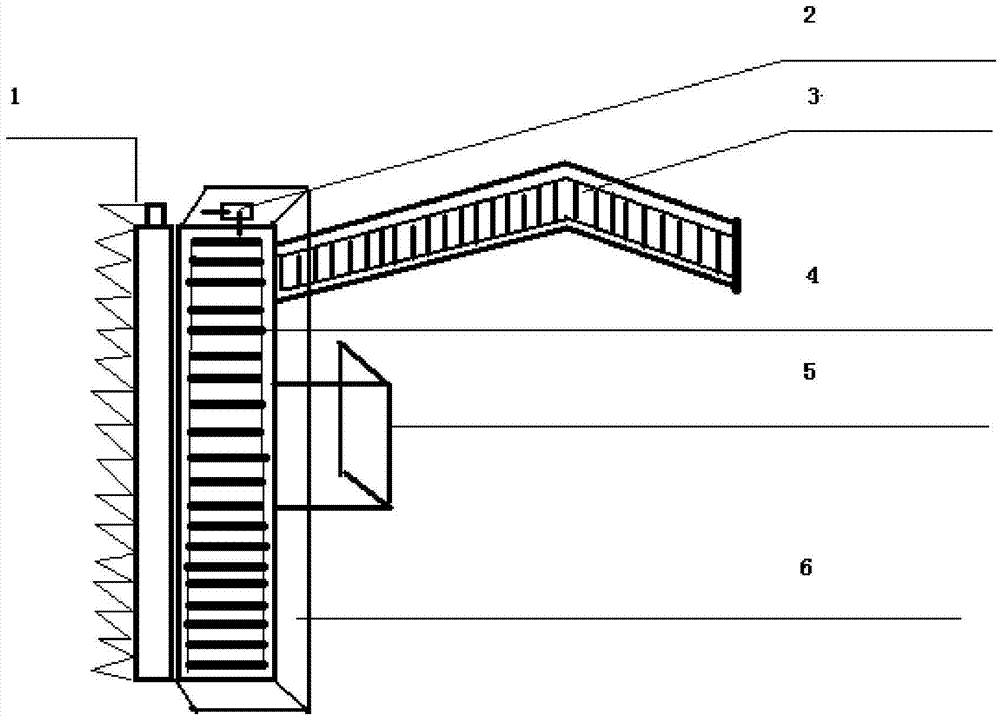

Mechanical cabbage harvester

A technology of mechanical harvesting and cabbage, applied to agricultural machinery and implements, harvesters, applications, etc., can solve problems such as labor-intensive, unsafe, and vulnerable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] When adopting the above-mentioned cabbage mechanical harvester, earlier the cabbage mechanical harvester is articulated on the power traction machinery (four-wheel machine or walking tractor head position), and the adjustment is suitable for height. Then start the power equipment (four-wheel machine) to drive the reducer of the cabbage harvesting equipment to move, the lower cutting section of the header moves, grinds with the upper cutting piece, the cabbage is cut off immediately, enters the blocking frame, and then transports the cabbage through the header conveyor belt to the mouth of the box conveyor belt, and then transported to the four-wheel box bucket by the box conveyor belt for transport.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com