Rape grading reaping machine

A harvester and rapeseed technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of high harvest loss rate, bursting of mature fruit pods, small rapeseed particles, etc., to extend the harvest period and reduce power consumption Small, the effect of reducing the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

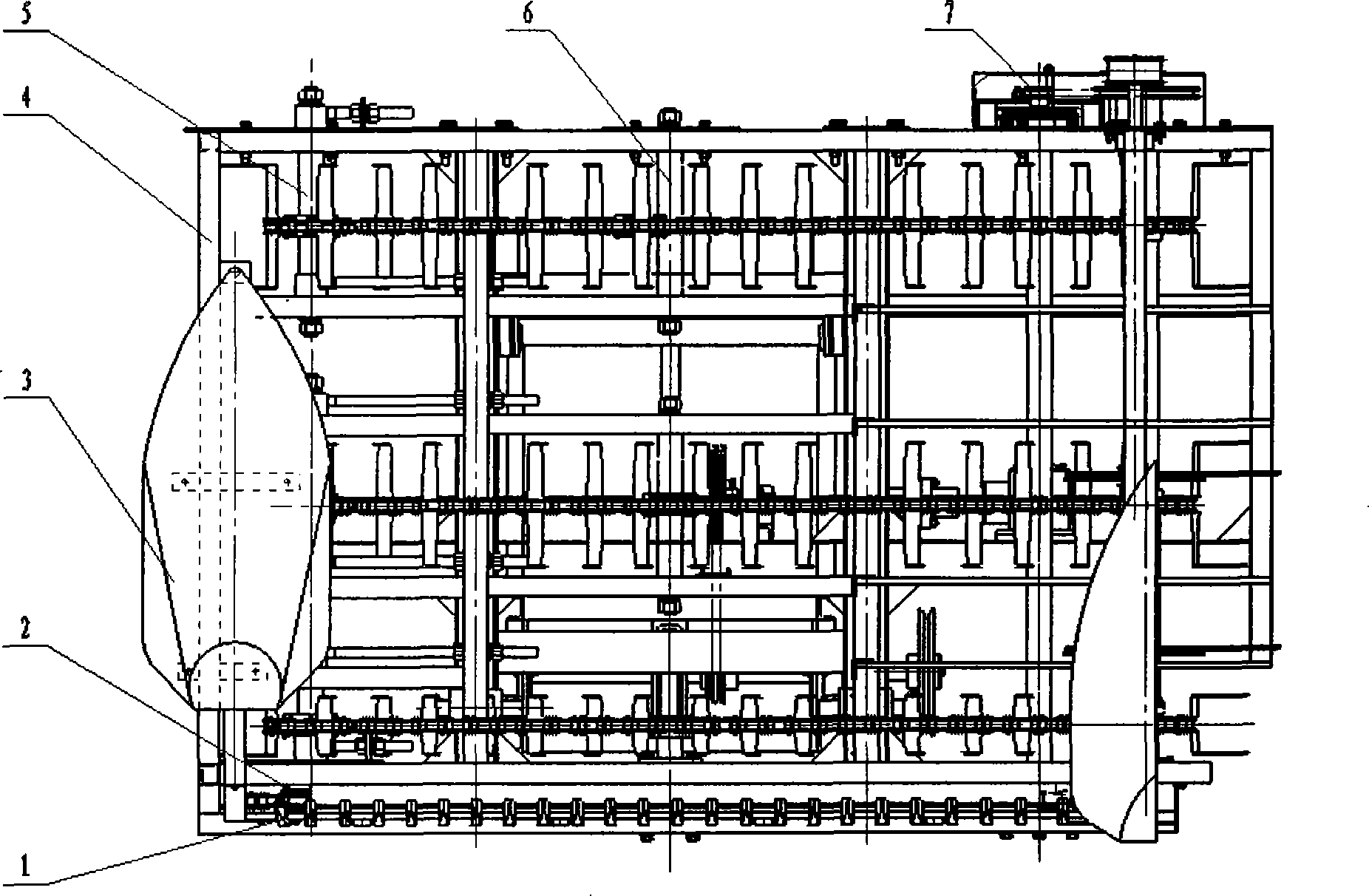

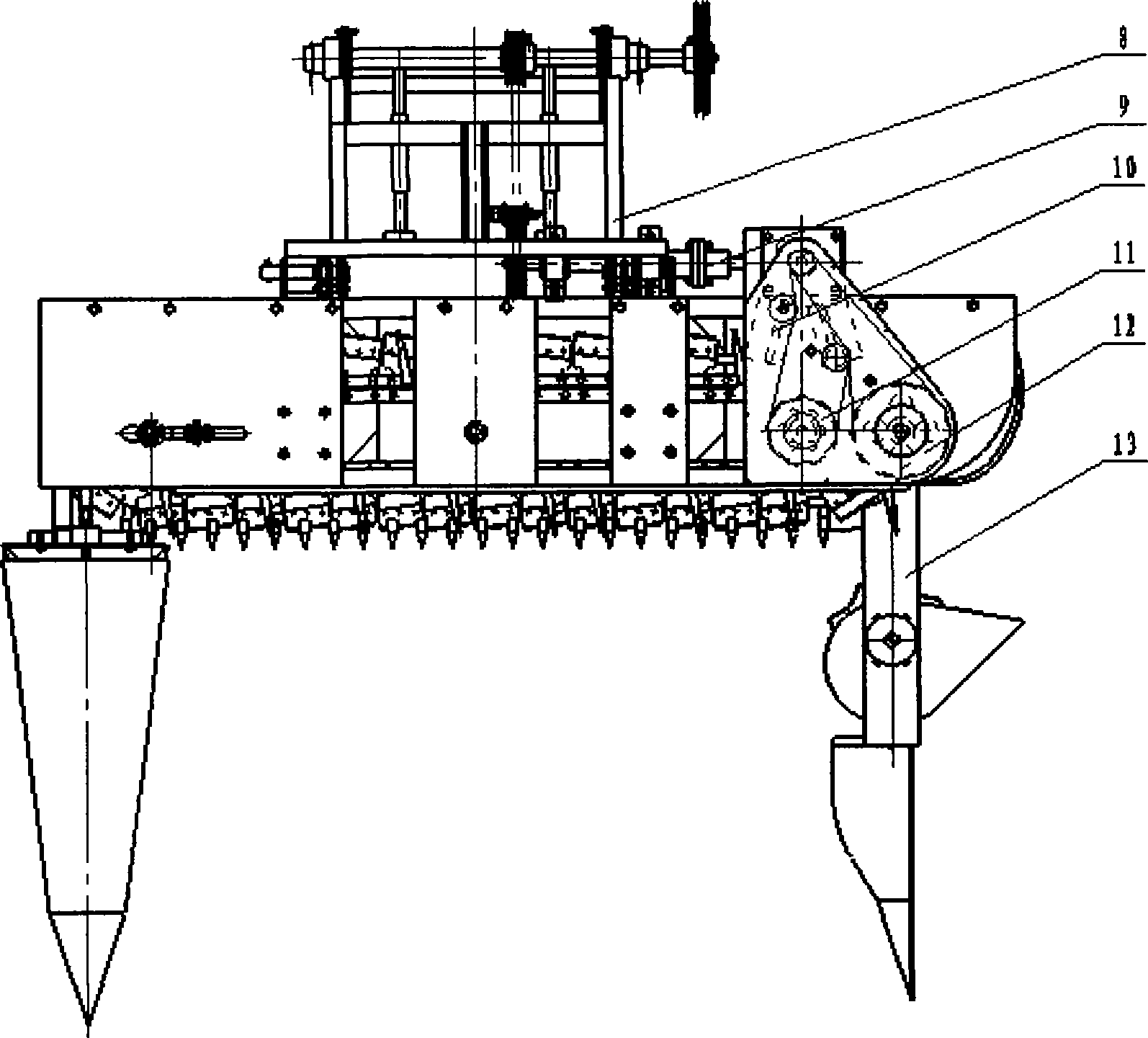

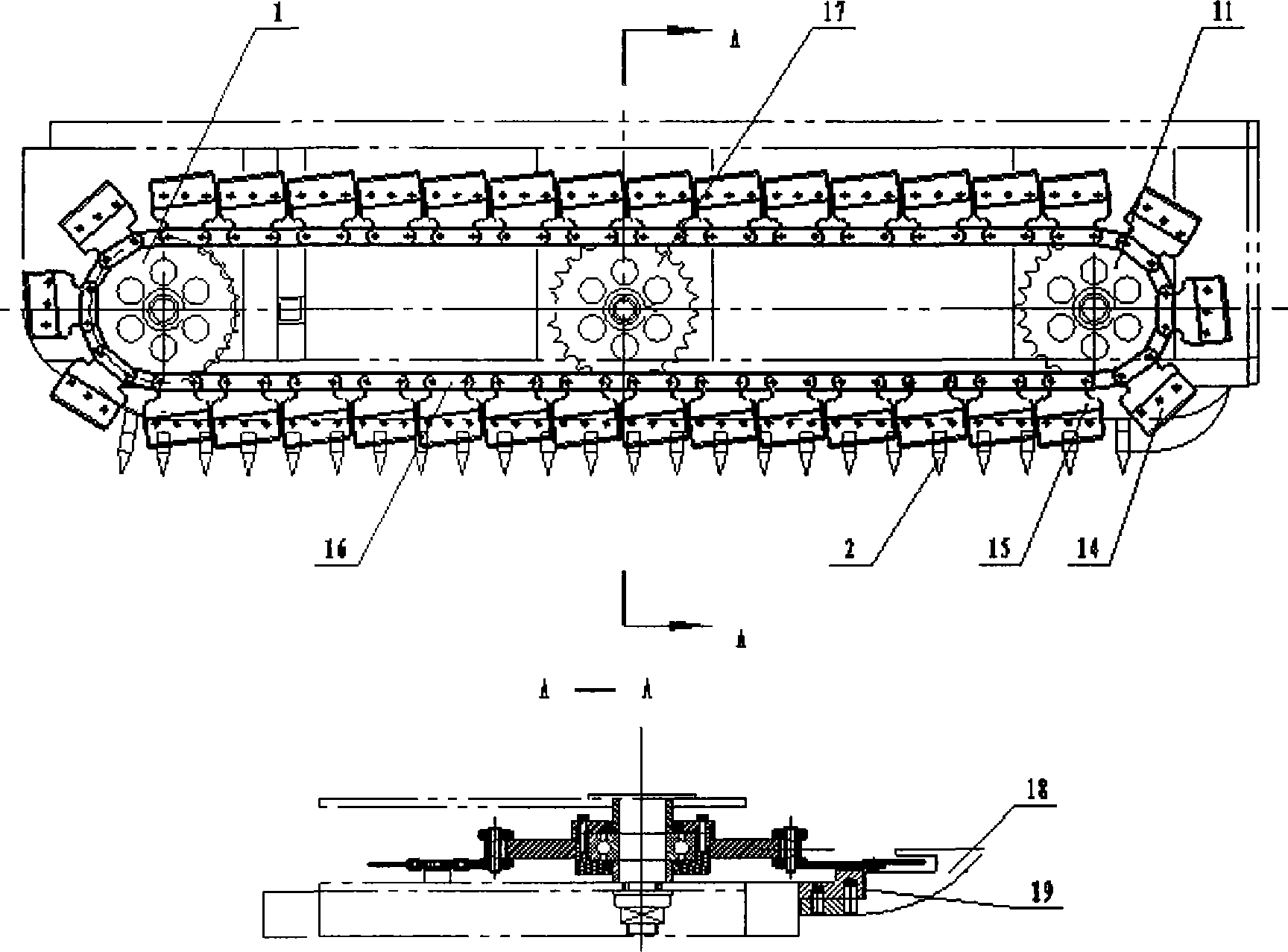

[0030] The sectioned rapeseed harvester is composed of a cutting system, a conveying system, an active conveying and laying device 13, a main transmission device 7, a suspension device 8, a passive grain dividing device 3, a transition device combination 6, a main transmission tensioning device combination 10, and The rack consists of 4. The cutting system includes active cutting device 11 and driven cutting device 1, driven cutting device 1 is installed on the right side of frame 4, and active cutting device 11 is installed on the left side of frame 4; Include active conveying device 12 and driven conveying device 5 in the system, active conveying device 12 is also installed in the left middle part of frame 4, and the main shaft of active conveying device 12 and described active cutting device 11 is in the same vertical plane, The active cutting main shaft is on the right side of the active conveying main shaft, and the driven conveying device 5 is installed directly above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com