Harvester

A harvester and frame technology, applied in the field of harvester, can solve the problems of large machine size, complex structure, inconvenient material collection, etc., and achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

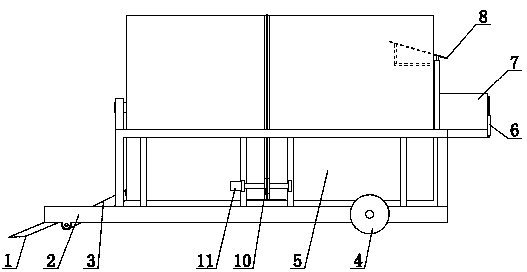

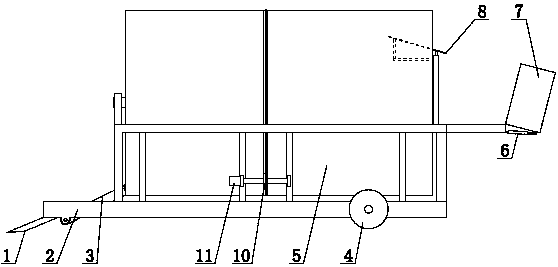

[0018] As shown in Figure 1 and Figure 2, the harvester includes a frame 2 and a blade 1, the frame 2 is provided with a wheel 4, and the frame 2 is located behind the blade 1 and is sequentially provided with a lifting conveyor 3 and a separating The drum 5 and the separation drum 5 are rotated and installed on the frame 2. The blade 1 and the separation drum 5 are connected by the lifting conveyor 3. The connection refers to the function of the lifting conveyor 3 transferring materials between the blade 1 and the separation drum 5. connection method. The front part of the separation drum 5 is a spiral conveyor drum, and the rear part of the separation drum is a lifting conveyor drum. The screw conveyor drum and the lifting conveyor drum share a cylinder with a screen-like wall. The frame 2 is also equipped with a front end inserted into the lifting conveyor The rear end of the conveying drum stretches out to the slide plate 8 on the rear side of the lifting drum. The slide p...

example 2

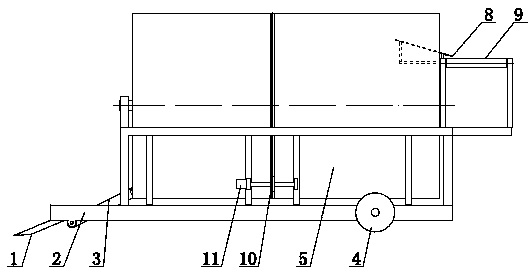

[0024] As shown in Figure 3, the difference between this specific embodiment and Example 1 is that this example uses a transfer conveyor 9 to replace the collection basket 7, and the transfer conveyor 9 is arranged on the frame 2, and the transfer conveyor 9 is located behind the slide plate 8 Below the end, the output end of the transfer conveyor 9 is positioned at the left or right side of the frame 2.

[0025] Working principle: The difference between the working principle and Example 1 is that the material on the slide plate 8 slides onto the transfer conveyor 9, the collecting vehicles drive side by side beside the frame, and the transferring conveyor 9 directly transports the materials into the bucket of the collecting vehicle .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com