Pressure sensor and pressure sensor module

A technology of pressure sensor and substrate, which is applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc. It can solve the problems of unstable electrical characteristics of pressure sensors and the inability of the shell to support the pressure sensor stably, and achieve a reliable waterproof structure. , Stable bonding, and the effect of inhibiting wetting and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

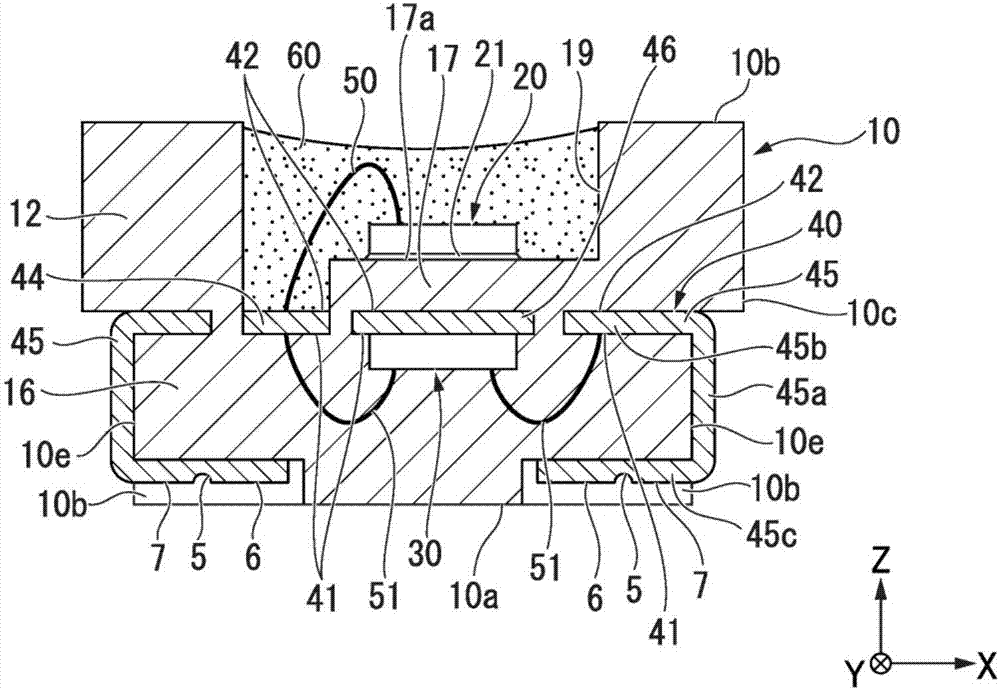

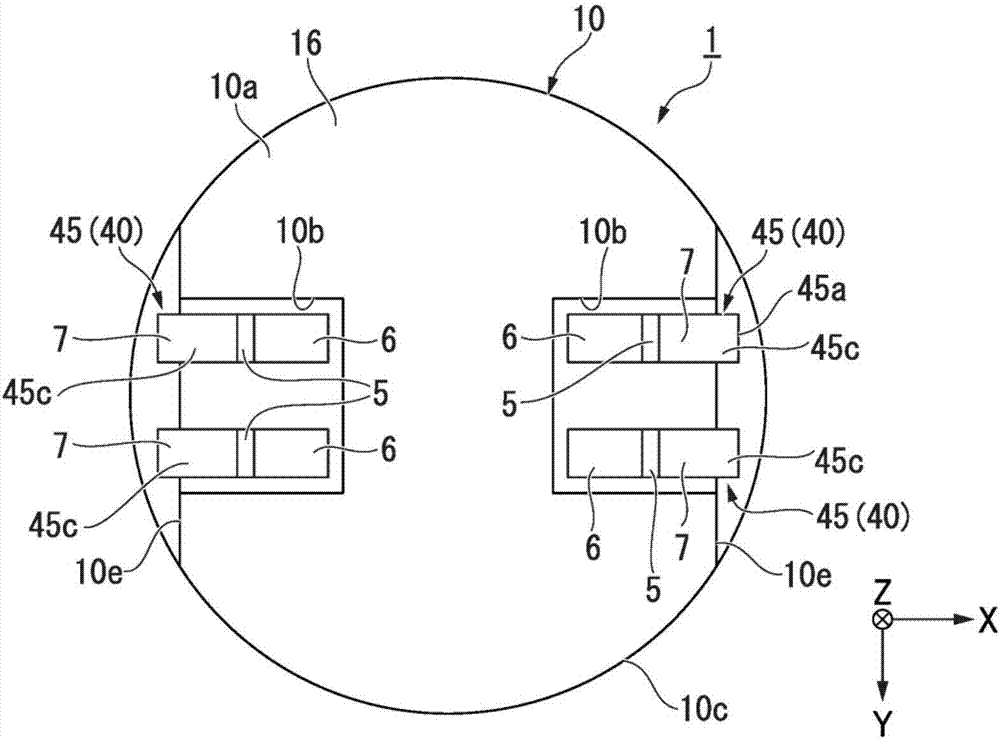

[0046]Figure 1A It is a sectional view of the pressure sensor 1 of the first embodiment. in addition, Figure 1B is a bottom view of the pressure sensor 1. In the description of the pressure sensor 1 of the present embodiment, "up" means the +Z direction, and "down" means the -Z direction. The bottom view is a plan view of the pressure sensor 1 viewed from below.

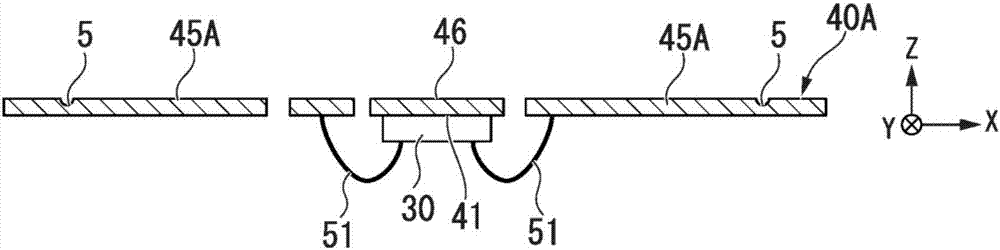

[0047] Such as Figure 1A , Figure 1B As shown, the pressure sensor 1 of the present embodiment includes a pressure sensor element 20 , a lead frame 40 electrically connected to the pressure sensor element 20 , and a resin base 10 supporting the pressure sensor element 20 and the lead frame 40 . In addition, the pressure sensor 1 has a control element 30 .

[0048] The base body 10 is integrated by embedding the lead frame 40 , the control element 30 , and the bonding wire 51 in the resin of the base body 10 . Thereby, the lead frame 40, the control element 30, and the bonding wire 51 are buried, and can be sh...

no. 2 approach

[0142] Next, a second embodiment will be described.

[0143] Figure 8 It is a bottom view of the pressure sensor 2 of the second embodiment, which is the same as that of the first embodiment Figure 1B corresponding figure.

[0144] In the pressure sensor 2 of the second embodiment, the shape of the concave portion 210b provided on the lower surface 210a of the base body 210 is different. In addition, the pressure sensor 2 of the second embodiment is different in the structure of the groove portion 205 provided in the terminal portion 45c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com