CNF cellular solid material with anionic surfactants

A technology of surfactants and porous solids, applied in flexible coverings, fiber raw material treatment, cellulose pulp post-treatment modification, etc., can solve the problems such as the difficulty in preparing large foams without cracks, and achieve good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Porous solid materials according to the invention and comparative examples are illustrated in the following examples.

[0088] Material

[0089] Cellulose Nanofibers (CNF). Different grades of Cellulose Nanofibers (CNF) were used to prepare porous solid materials. The different levels are described below.

[0090] Similar to a previously described method (Henriksson et al., 2007), enzyme-modified CNF (Enz-CNF) was prepared from pulp fibers subjected to enzymatic pretreatment and then defibrillated in a high-pressure homogenizer.

[0091] TEMPO-CNF was prepared from commercial sulfite softwood dissolving pulp with 4.5% hemicellulose content and 0.6% lignin content ( Dissolving Pulp; Fabriker AB, Sweden) prepared. The non-dried dissolving pulp fibers were oxidized using TEMPO according to the method previously described (Saito et al. 2007). The fibers were suspended in water containing TEMPO and NaBr. TEMPO-mediated oxidation of cellulose fibers was initiated ...

Embodiment 15

[0116] Example 15 illustrates porous solid materials dried at different temperatures.

Embodiment 1

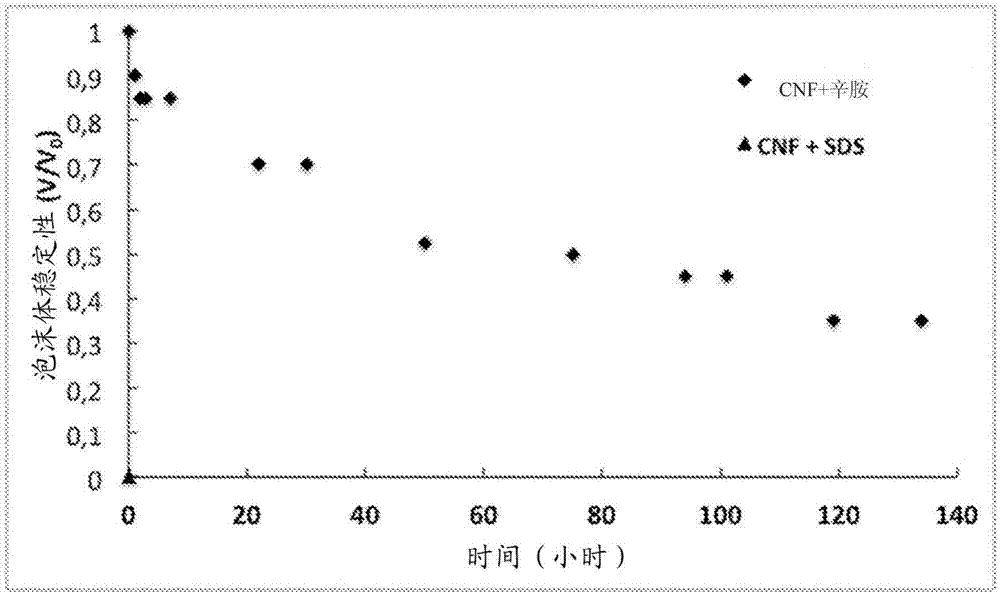

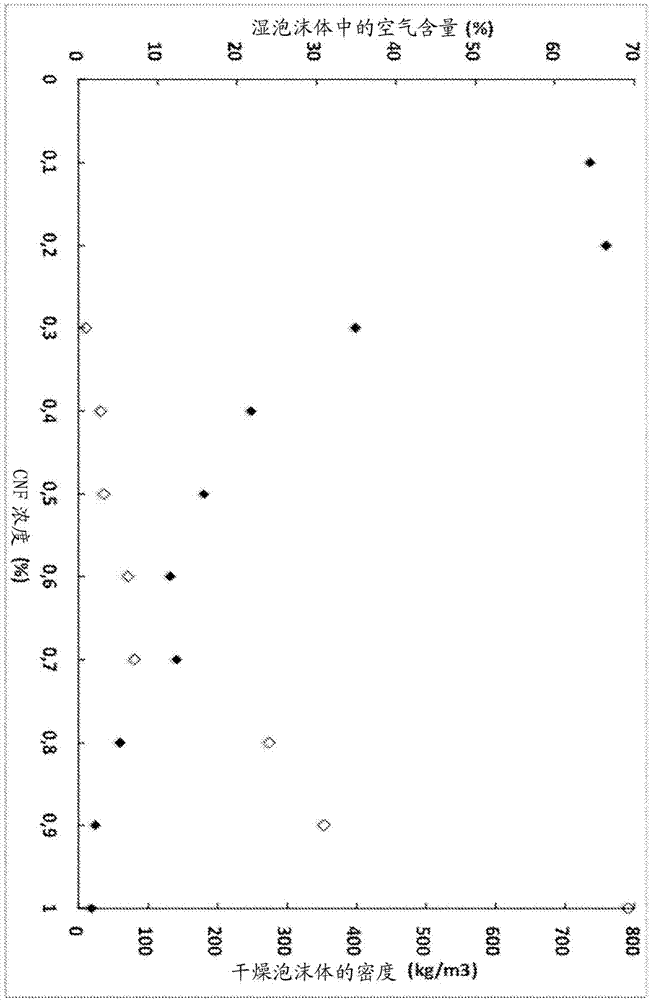

[0118] Different types of surfactants were used to prepare porous solid CNF materials with retained porous structures. 30 g of TEMPO-oxidized anionic CNF dispersion (0.5 wt%, surface charge 983 μeq / g) were combined with different anionic surfactants, see Table 1 . The different combinations were mixed, adjusted to pH 8, and foamed for 5-10 minutes using a laboratory mechanical stirrer at 2000 rpm with a small impeller (diameter = 3 cm). The resulting wet foam was poured into plastic trays and dried in a fan oven at 40°C. Table 1 shows that a variety of anionic surfactants can be used to prepare porous solid CNF materials with retained porous structure. These examples were not optimized with respect to surfactant amount, density, pore size, thickness or mechanical properties.

[0119] Table 1. Porous solid CNF materials containing different surfactants.

[0120]

[0121] *) Calculated based on the total weight of the porous solid material

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com