A Mechanically Sealed Quadriaxial Cable Termination Process

A technology of mechanical seals and cable ends, which is applied in the field of nuclear measurement systems outside the core of nuclear power plants, and can solve problems such as waste of materials, low first-time success rate, and delayed construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0165] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

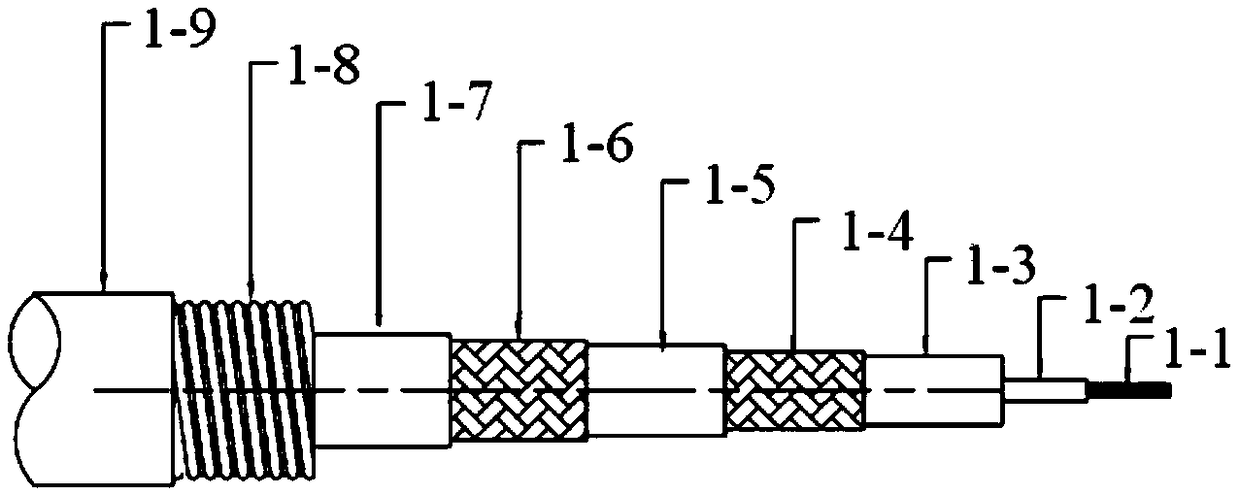

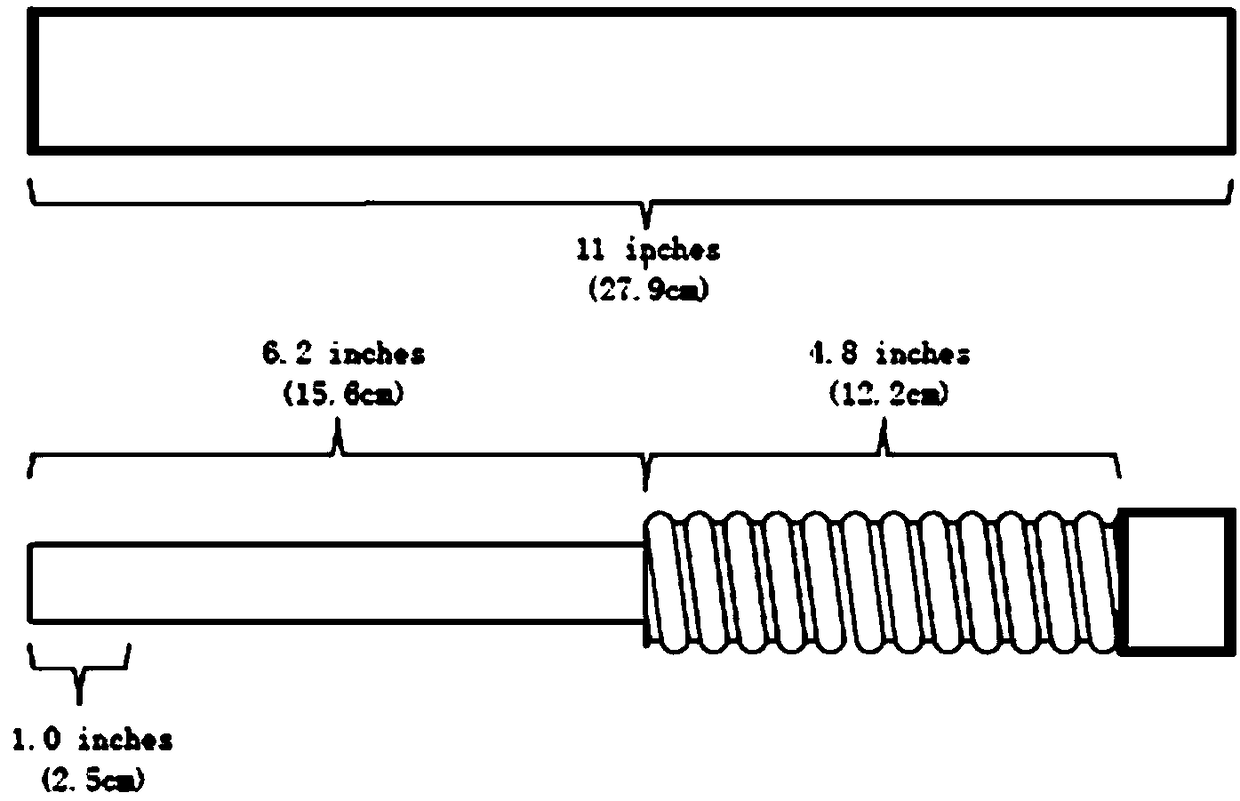

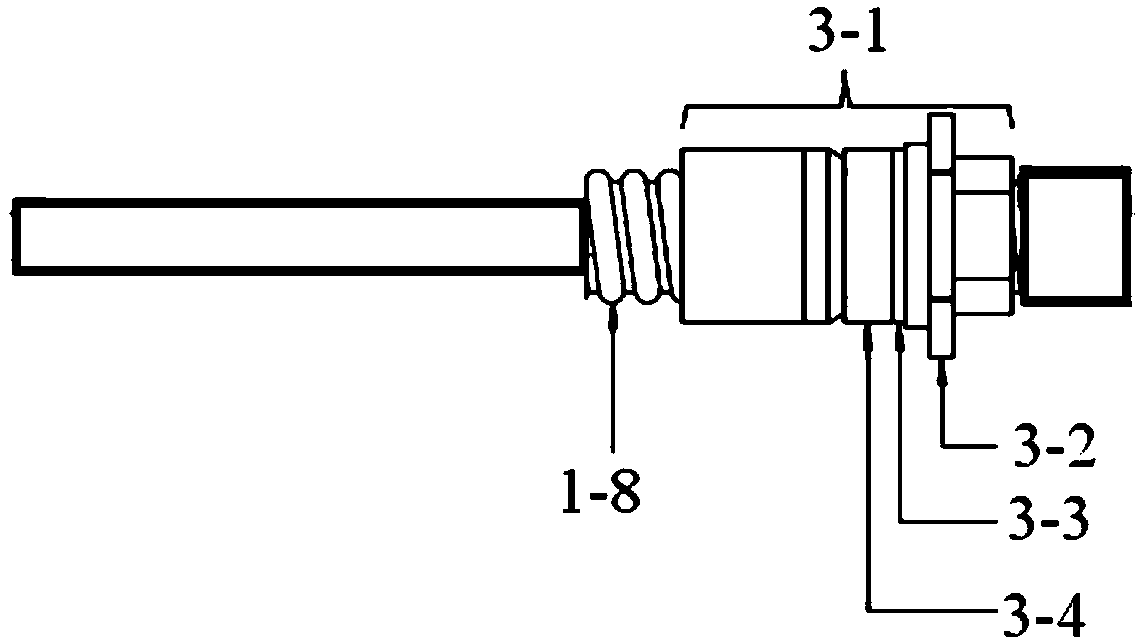

[0166] The present invention is a mechanically sealed four-coaxial cable termination process, AP1000 nuclear power plant nuclear measurement system (NIS), such as Figure 35 As shown, it includes the following steps:

[0167] Step 1. Termination preparations include the following aspects:

[0168] Step 1.1, select the production environment temperature to be above 0°C and relative humidity below 80%;

[0169] Step 1.2, clean up the sundries, including dust, to ensure that the environment during the entire termination process is clean;

[0170] The above step 1.2 starts after the cold test of the unit. At this time, there is no work on the production site that affects the environment, and the leakage of various pipes has basically been eliminated;

[0171] Step 1.3, make a simple operating table, and clamp a table vise on the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com