A Modal Modeling Method for Dual Drive Feed System of CNC Machine Tool

A dual-drive feed and CNC machine tool technology, applied in general control systems, control/adjustment systems, simulators, etc., can solve problems such as cumbersome finite element software simulation operations and unsolvable continuous system vibration equations, etc., to achieve good reliability. Operability, intuitive modeling method, good operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

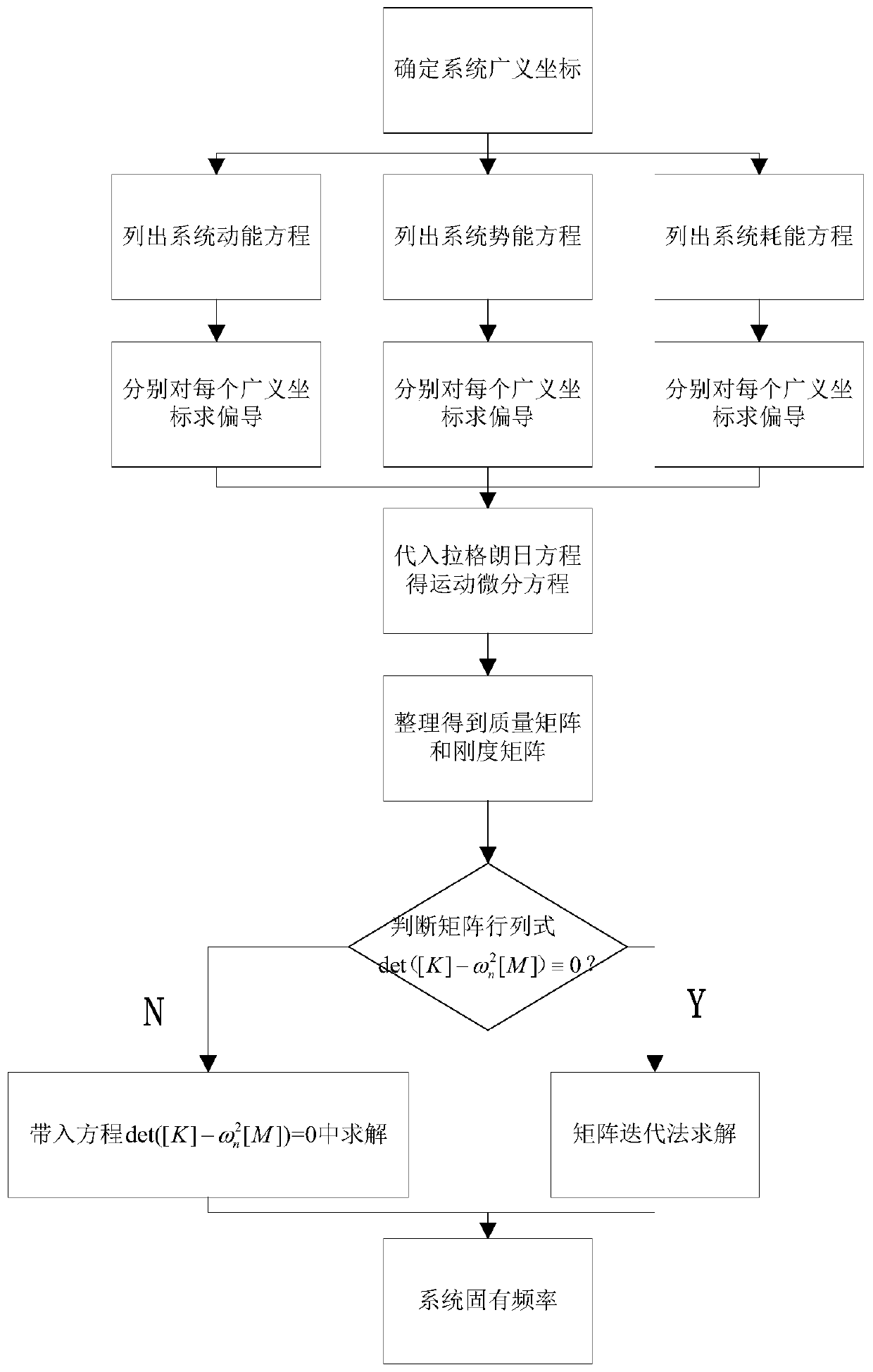

[0025] combine figure 1 A schematic flow chart of the present invention, a dual-drive feed system modal modeling method for a CNC machine tool of the present invention, comprising the following steps:

[0026] Step 1. Determine the generalized coordinates of the system: determine the degrees of freedom of the system, and select generalized coordinates to describe the motion state of the system, and the number of coordinates is the same as the number of degrees of freedom.

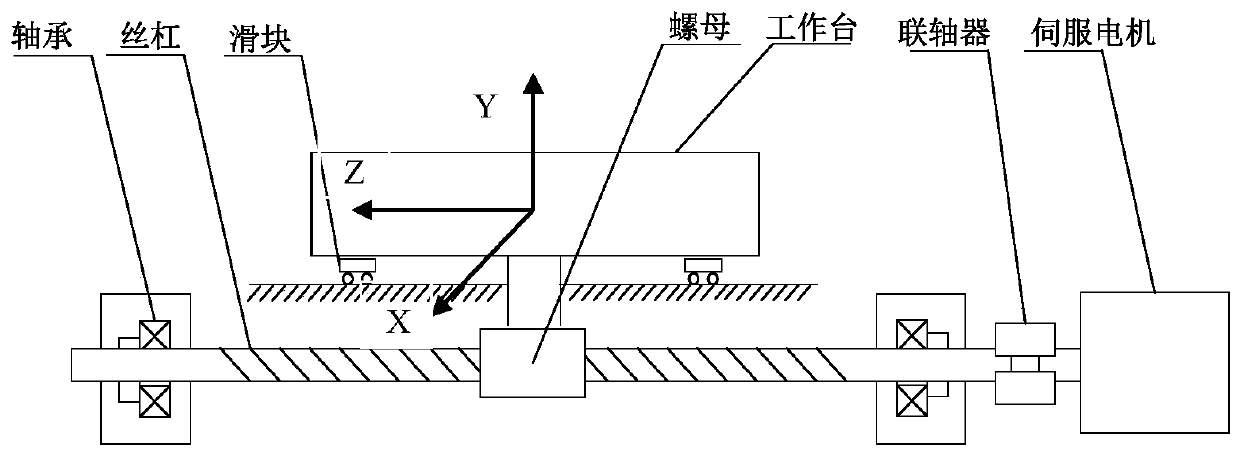

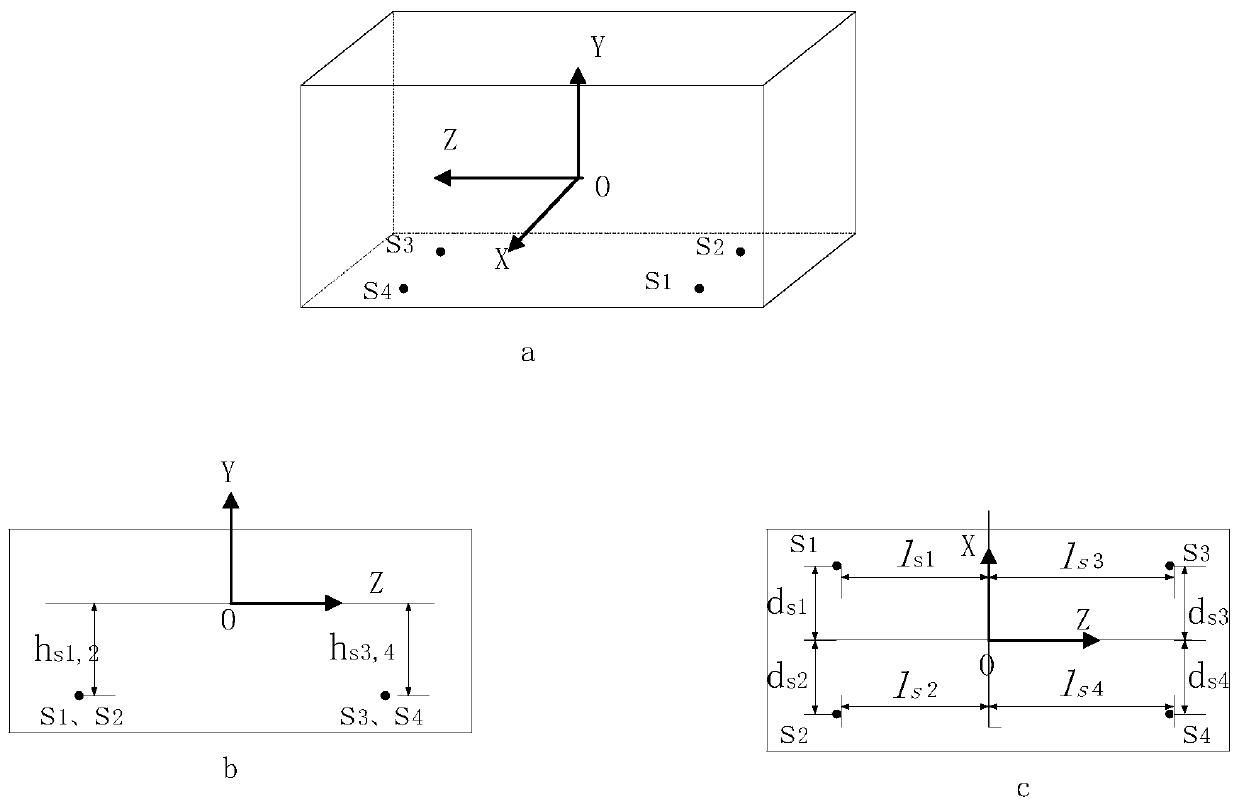

[0027] combine figure 2 , taking the position of the center of gravity of the worktable in a static state as the coordinate origin, establish the O-XYZ main coordinate system, the positive direction of the X-axis is perpendicular to the guide rail, the positive direction of the Y-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com