A low-speed heavy-duty gear crack fault online detection method

A detection method, low-speed heavy-duty technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of low vibration signal characteristic frequency, low signal-to-noise ratio, submersion, etc., to achieve good Effect of anti-interference and accuracy, high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] An enterprise needs to conduct online monitoring of the running status of the main reduction gear of the axle, so as to detect the early failure of the gear in time and lock the weak link of the gear design. Usually, the condition monitoring of gears based on vibration information is selected, but under low-speed and heavy-load conditions, the signal-to-noise ratio of the vibration signal of the gear is low, and it is easily disturbed, and the early failure of the gear cannot be found in time. The invention solves the problem of low-speed and heavy-duty gears. condition monitoring problems.

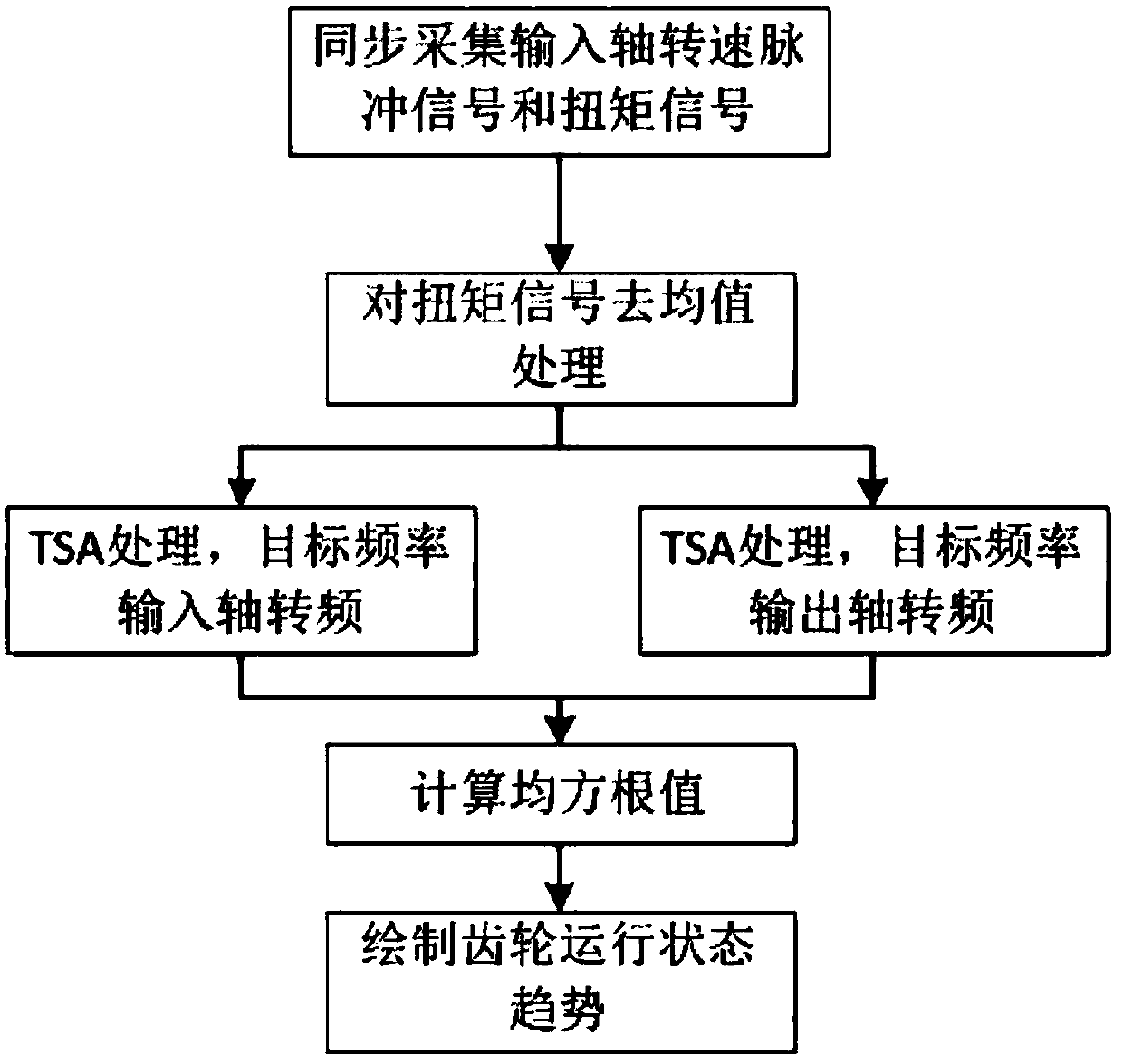

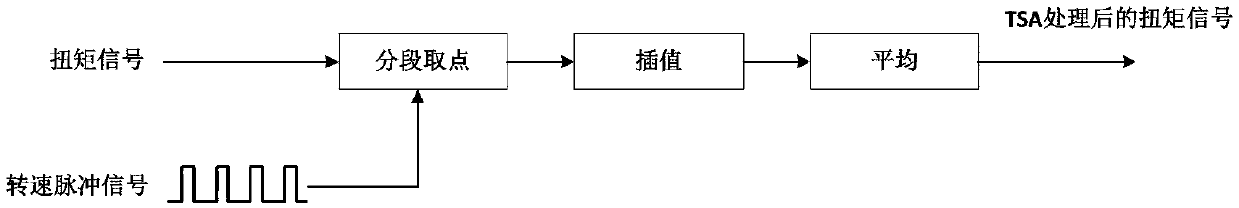

[0029] refer to figure 1 , a low-speed heavy-duty gear crack fault online detection method, comprising the following steps:

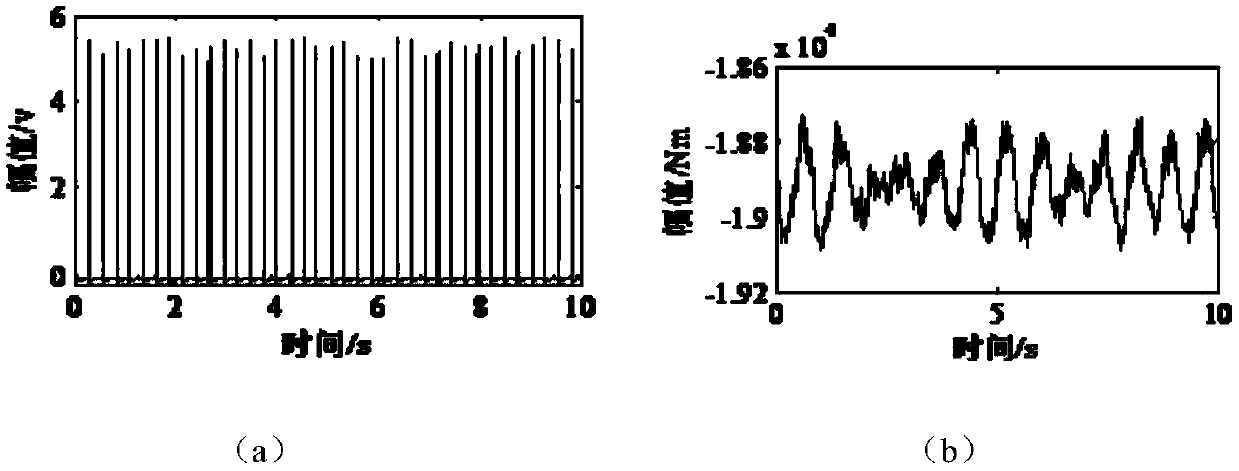

[0030] Step 1, installing a torque sensor at the motor shaft of the gear and the coupling of the gear shaft, and installing a ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com