Constant-temperature drying device

A technology of constant temperature drying and drying oven, which is applied in the direction of drying gas arrangement, local stirring dryer, and static material dryer, etc., can solve problems such as affecting processing effect, user loss, and results failing to meet predetermined requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

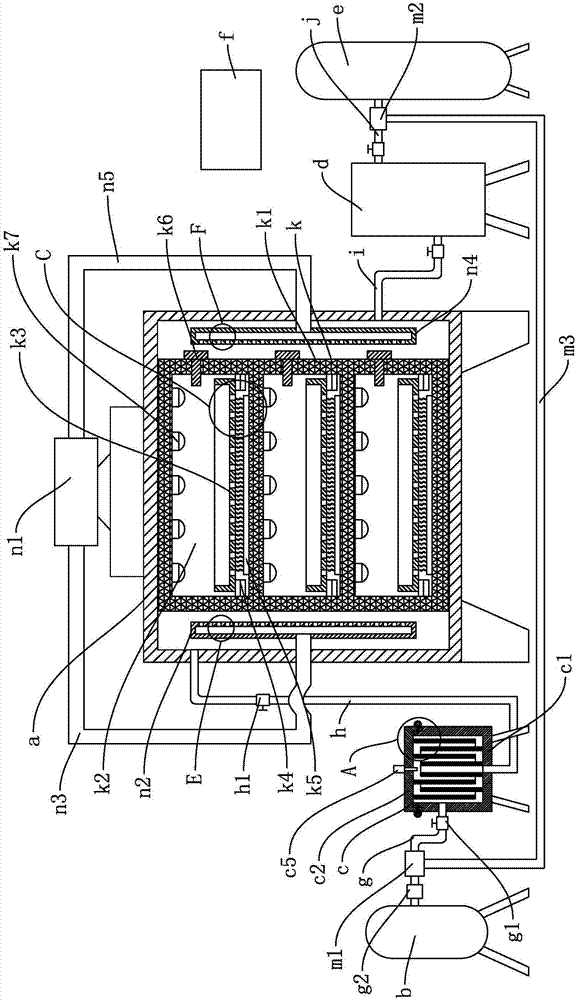

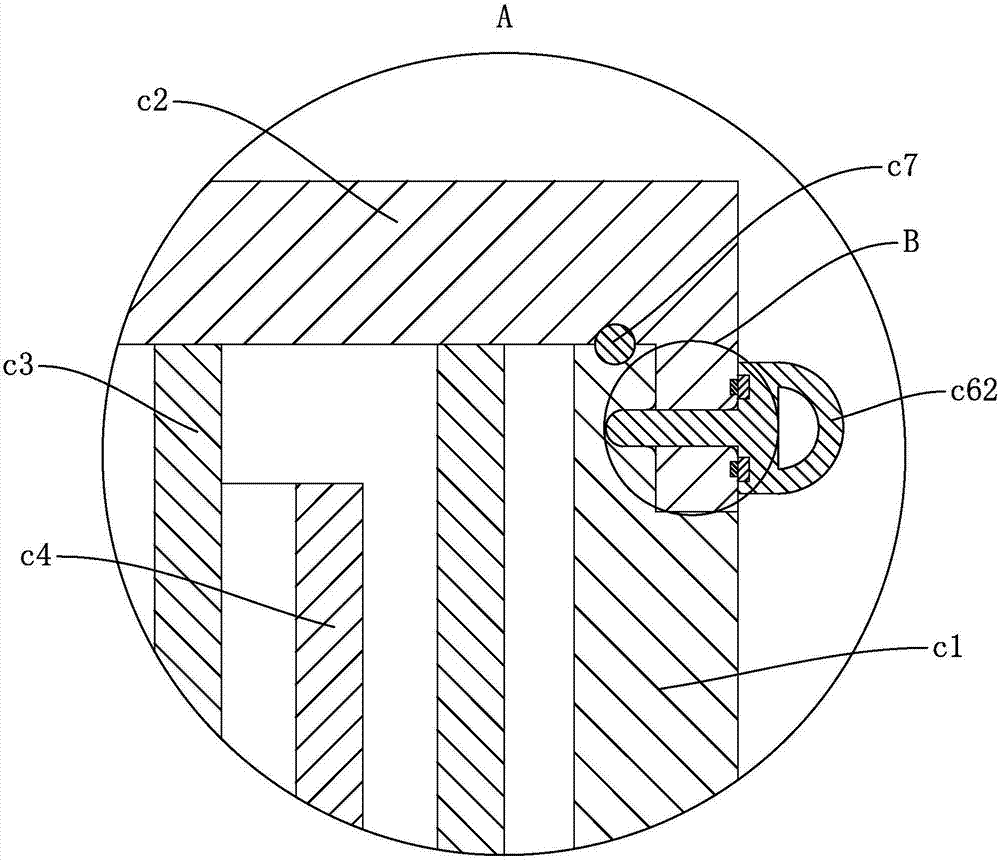

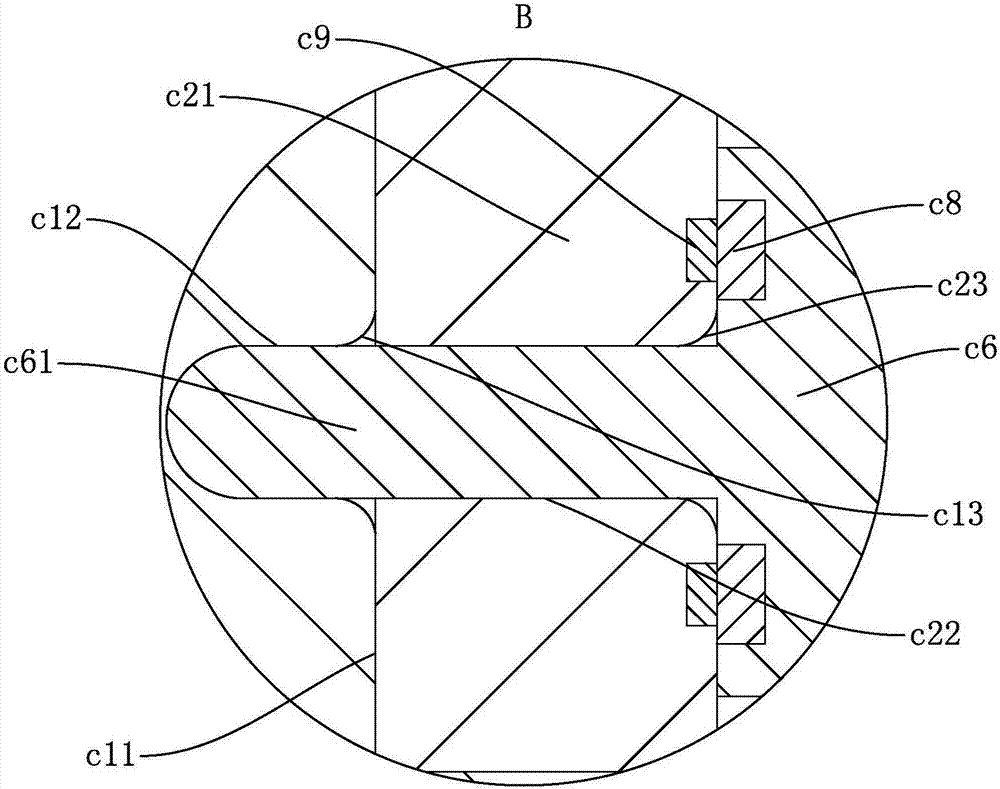

[0022] like Figure 1-7 The shown constant temperature drying device includes the drying box body a, the constant temperature drying device also includes an inert gas storage tank b, a buffer tank c, an air compression pump d, an exhaust gas collection tank e and a controller f, and the inert gas storage tank b passes through The first pipeline g communicates with the buffer tank c, the buffer tank c communicates with the dry box body a through the second pipeline h, the dry box body a communicates with the air compression pump d through the third pipeline i, and the air compression pump d passes through the second pipeline i The four pipelines j are connected with the waste gas collection tank e, and the inside of the drying box body a is provided with a drying rack k, and the side wall of the drying rack k is provided with several ventilation holes k1 distributed in a honeycomb shape, and the inside of the drying rack k is provided with There are several drying chambers k2 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com