Electromagnetic-control hydraulic drive type fully-variable valve mechanism

A technology of electromagnetic control and valve mechanism, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems that the valve movement parameters cannot be flexibly changed and fixed, and can be easily popularized, reduce pumping loss, and improve power Sexual and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

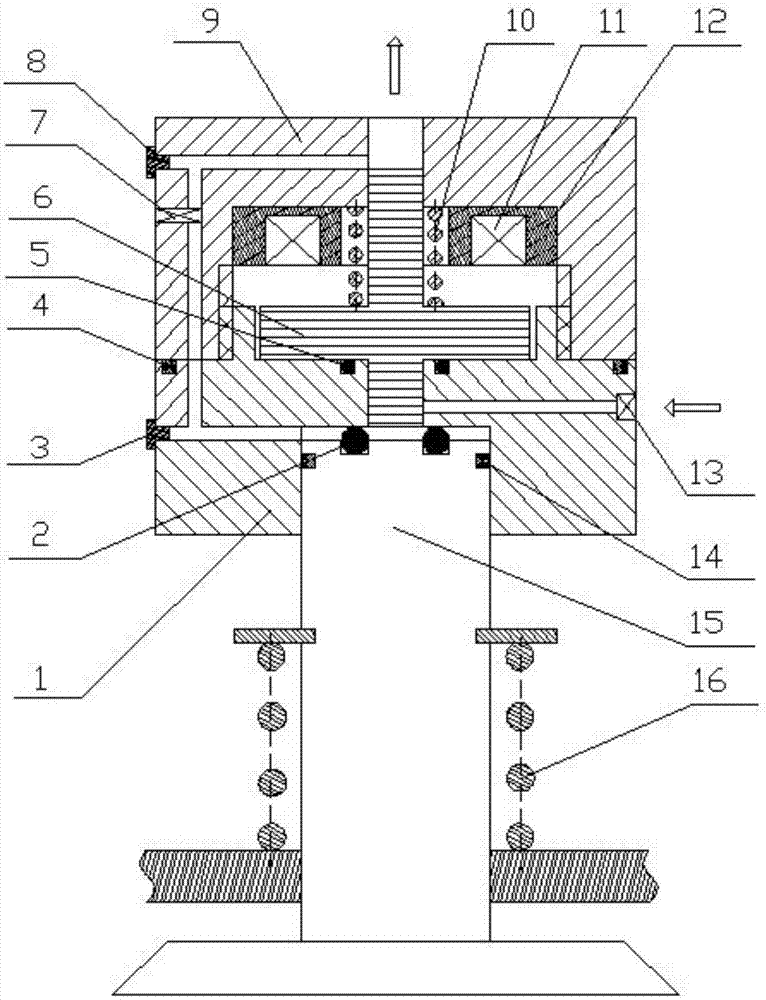

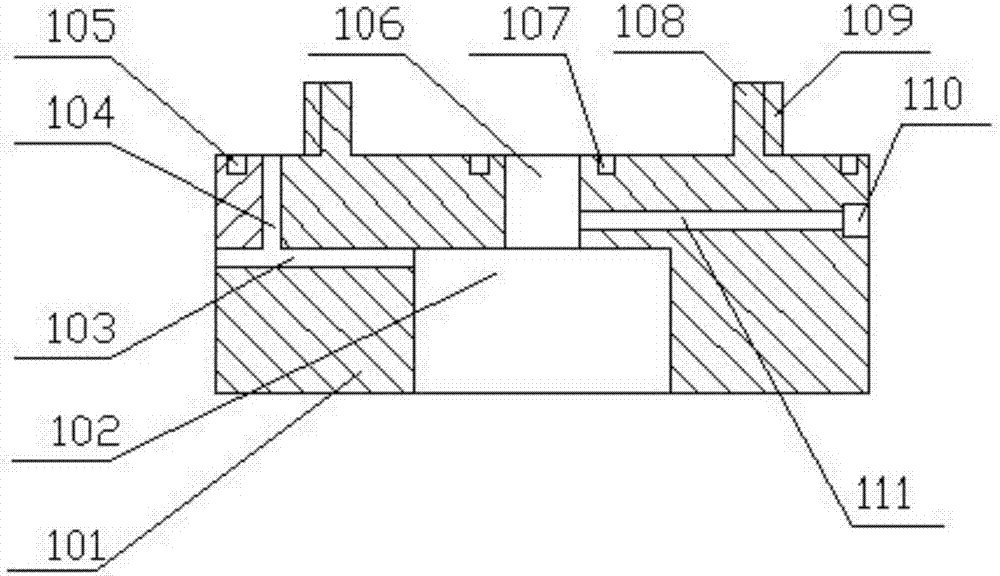

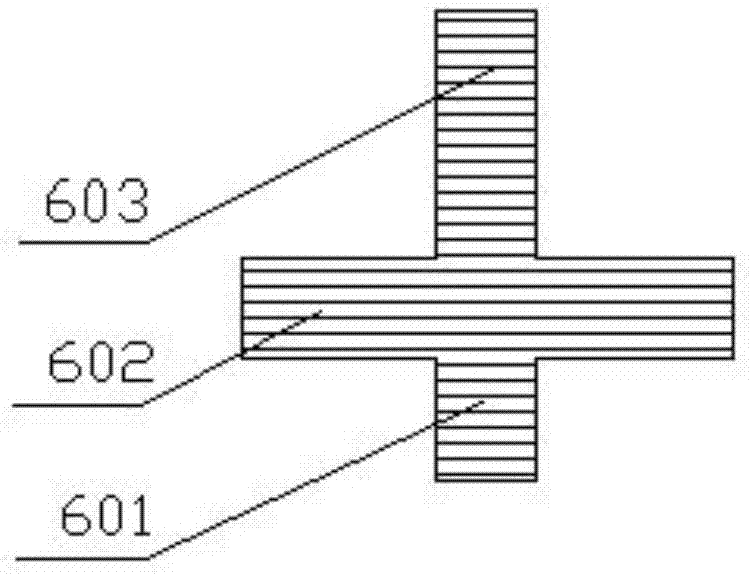

[0034] Attached below Figure 1-5 The present invention is described in detail:

[0035] Refer to attached figure 1 , 2, 3, 4, 5:

[0036] The present invention consists of control valve lower part 1, buffer ring a2, oil plug a3, sealing ring a4, buffer ring b5, valve core 6, electric control throttle valve 7, oil plug b8, control valve upper part 9, valve core return spring 10, Electromagnetic coil 11, insulating material 12, electric control pressure regulating valve 13, sealing ring b14, valve 15, valve return spring 16 are composed.

[0037] Wherein, the control valve lower part 1 and the control valve upper part 9 are connected through the outer thread 109 of the control valve lower part 1 and the inner thread 906 of the control valve upper part 9;

[0038] The buffer ring a2 is placed in the ring groove d1502 on the top of the valve 15 to provide buffering effect for the seat of the valve 15;

[0039] The oil plug a3 is placed outside the low-pressure oil passage a10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com