Construction technology for vibrocompaction of gravel pile of sediment storage dam of lower storage reservoir

A technology of vibrating and crushing stone piles and construction technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of long construction period, unsuitable engineering, and high construction cost, and achieve the improvement of overall compactness and pile side friction. The effect of enhanced strength and bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

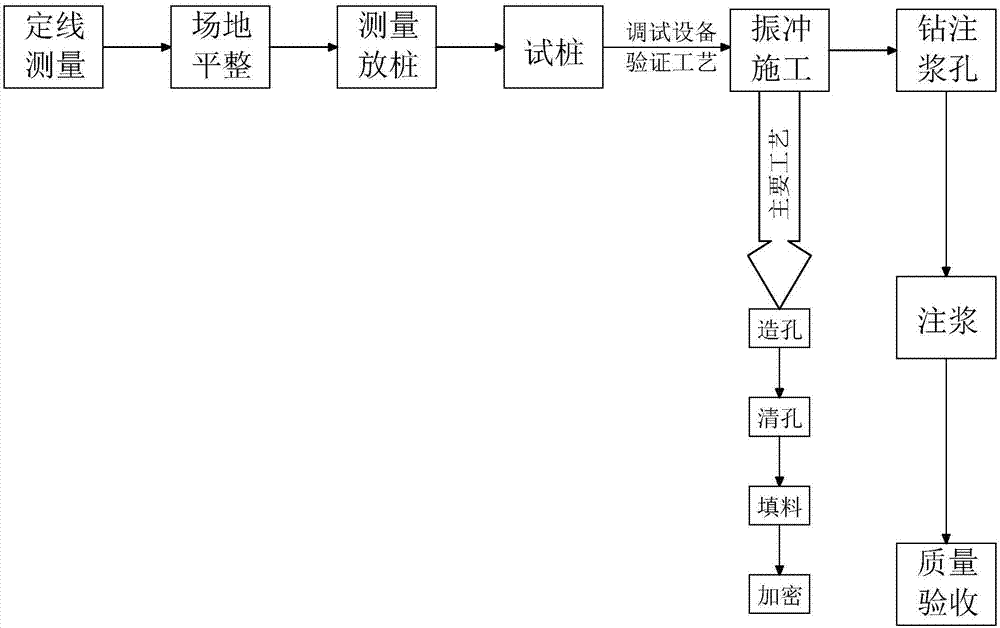

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications without creative contribution to this embodiment according to needs after reading this description, but as long as they are within the protection of the present invention are protected by patent law.

[0031] A construction technique for vibrating gravel piles used in a sand-holding dam of a lower reservoir. The technique includes the following steps:

[0032] S1: Clean up the site, connect the power supply and water source;

[0033] S2: The construction equipment is in place, and the lifting vibrator is aligned with the pile position;

[0034] S3: Hole making:

[0035] (a) Align the vibrator with the pile position, first turn on the pressure water pump, and then start the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com