Monitoring system for monitoring vibration strength and amplitude of vibrating motors

A technology of vibration intensity and vibration motor, applied in the direction of circuit, electrolysis process, electrolysis components, etc., can solve the problems of broken holes in PCB boards, high defect rate of PCB boards, and substandard perforation rate of liquid medicine, etc., to improve TP value and increase The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

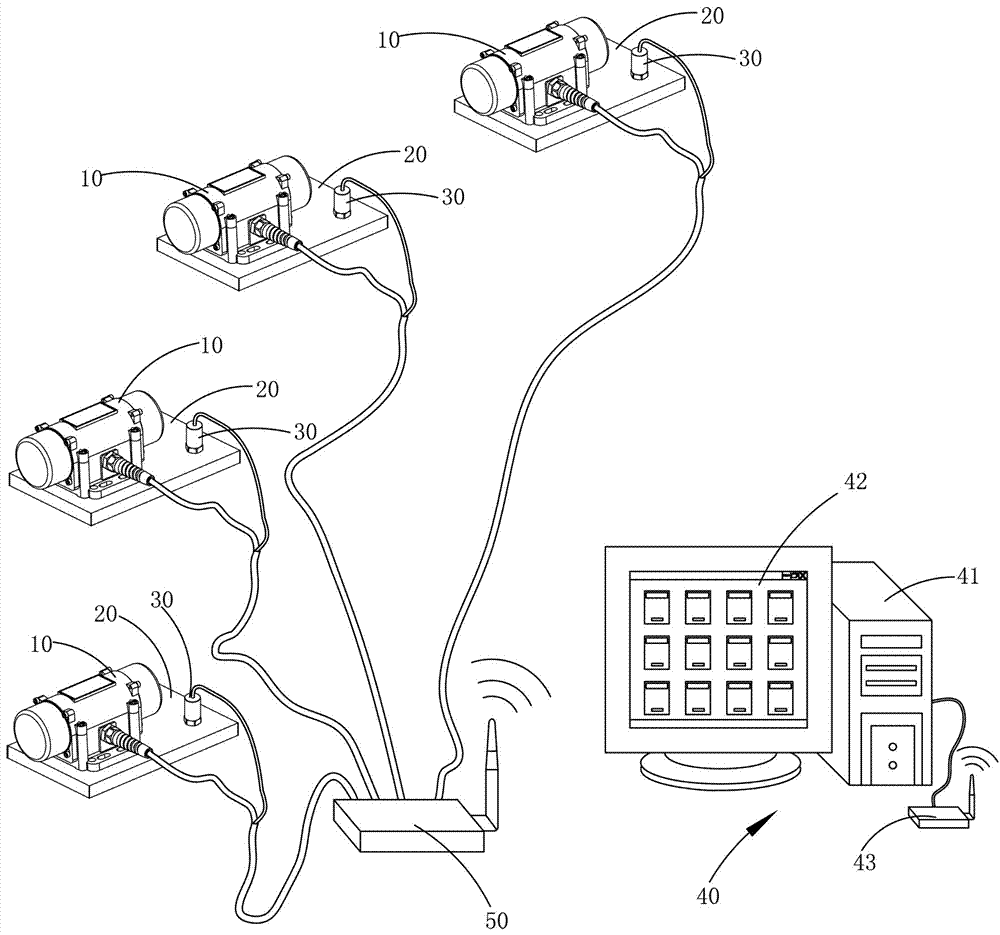

[0014] figure 1 , is a preferred embodiment of a monitoring system for monitoring the strength and amplitude of a vibration motor provided by the present invention. Such as figure 1 As shown, the monitoring system includes several PCB plating tanks, vibration motors 10 and vibration steel plates 20 are installed on the swing frames on both sides of each PCB plating tank, vibration intensity sensors 30 are installed on each vibration steel plate 20, and vibration intensity The sensor 30 is wirelessly connected with the monitoring host 40, and each vibration intensity sensor 30 is used to collect vibration intensity and amplitude signals of the vibration motor 10. The monitoring host 40 is provided with a main control module 41 and a display module 42, and the main control module 41 is used to receive each The vibration intensity and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com