Method and system for dosing boiler water

A boiler water and dosing pump technology, applied to controllers with specific characteristics, electric controllers, etc., can solve the problems of data acquisition lag and low accuracy of boiler water dosing adjustment, so as to reduce labor intensity and avoid adverse accidents , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

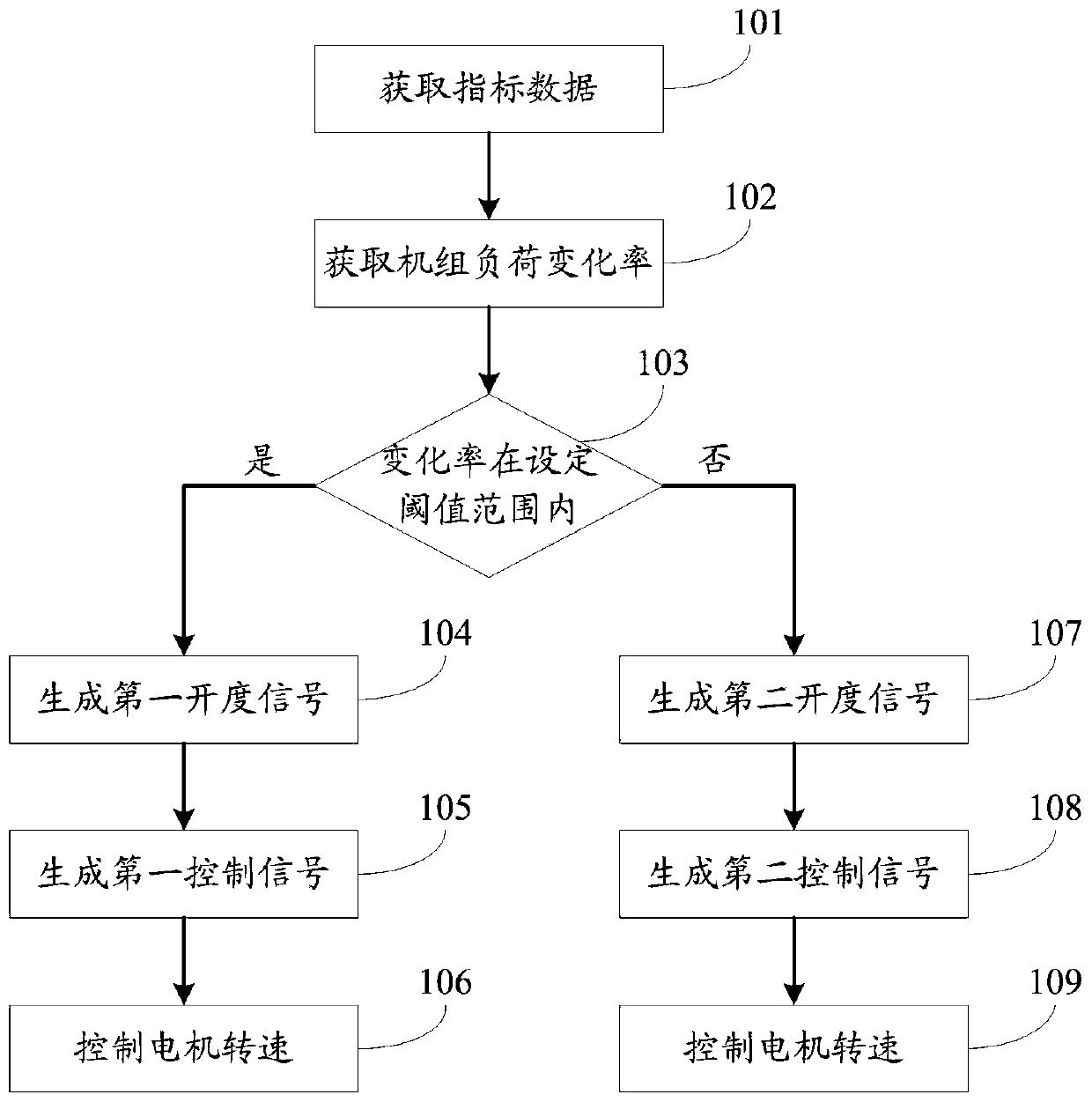

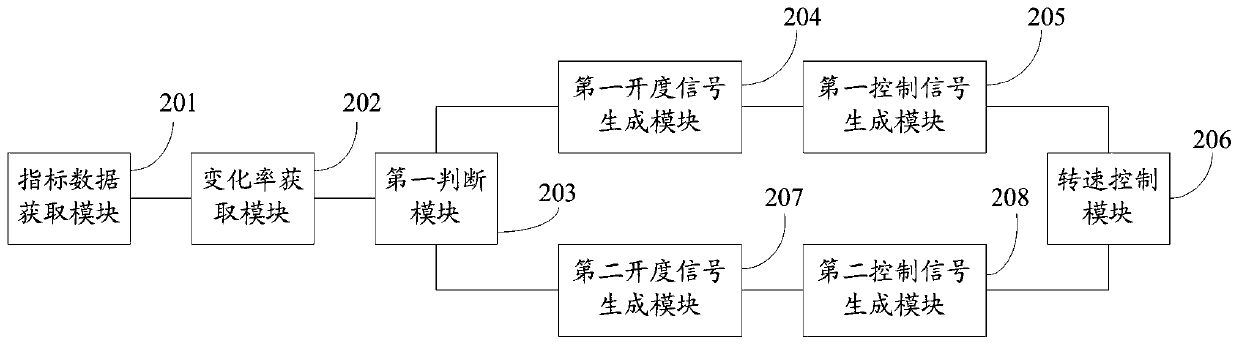

[0061] figure 1 It is the flow chart of Embodiment 1 of the furnace water dosing method of the present invention. Such as figure 1 As shown, the method includes:

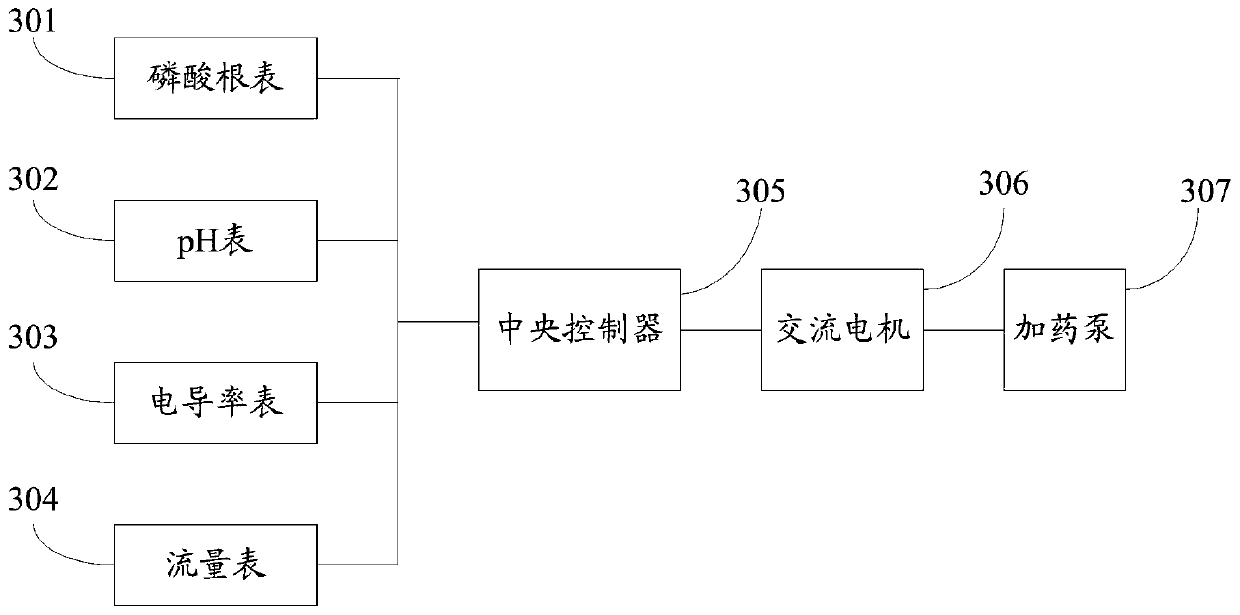

[0062] Step 101: Obtain indicator data. Obtain indicator data in the boiler water sample, the indicator data including phosphate concentration, pH, conductivity and feed water. The index data is transmitted to the central controller in the form of phosphate concentration table, conductivity table, pH table, and water supply meter.

[0063] Step 102: Obtain the rate of change of unit load. Real-time monitoring of unit load change rate, that is, the speed of unit load increase or decrease.

[0064] Step 103: Determine whether the rate of change is within a set threshold range. The purpose of judging whether the rate of change is within the range of the set threshold is to judge whether the state in the boiler water at this time is the state of make-up water. The range of the set threshold can be 5MW / min~7MW / min...

Embodiment 2

[0087] The furnace water of a 600MW subcritical wet-cooled coal-fired unit is treated with phosphate, and the continuous dosing method is adopted. The pH value of the furnace water is 9-10. The amount of phosphate added should ensure: when the load is low, maintain PO 4 3- At 0.5-3mg / L; at moderate load, maintain PO 4 3- At 0.5-1.5mg / L; at high load, maintain PO 4 3- At 0.5-1mg / L. When the condenser leaks, the amount of phosphate added should be increased to maintain PO 4 3- In 2 ~ 10mg / L, and strengthen sewage treatment. At the same time, the pH value of the furnace water is required to be 9.0-10.0, and the conductivity is 5-25 μS / cm. Now adopt the multi-parameter collaborative automatic dosing control method of boiler water of the present invention, introduce four parameters of boiler water phosphate concentration, pH, DD, and feed water flow rate, and regulate the phosphate adding system. The method of combining AC frequency conversion technology and computer contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com