Wire collecting device integrated with air blowing function

A technology of air function and line-collection, applied in the field of optical cable production, can solve the problems of reinforcements, reinforcements and optical fiber routing obstruction, affecting the normal production of butterfly optical cables, and unsmooth routing, etc., and achieve the effect of improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

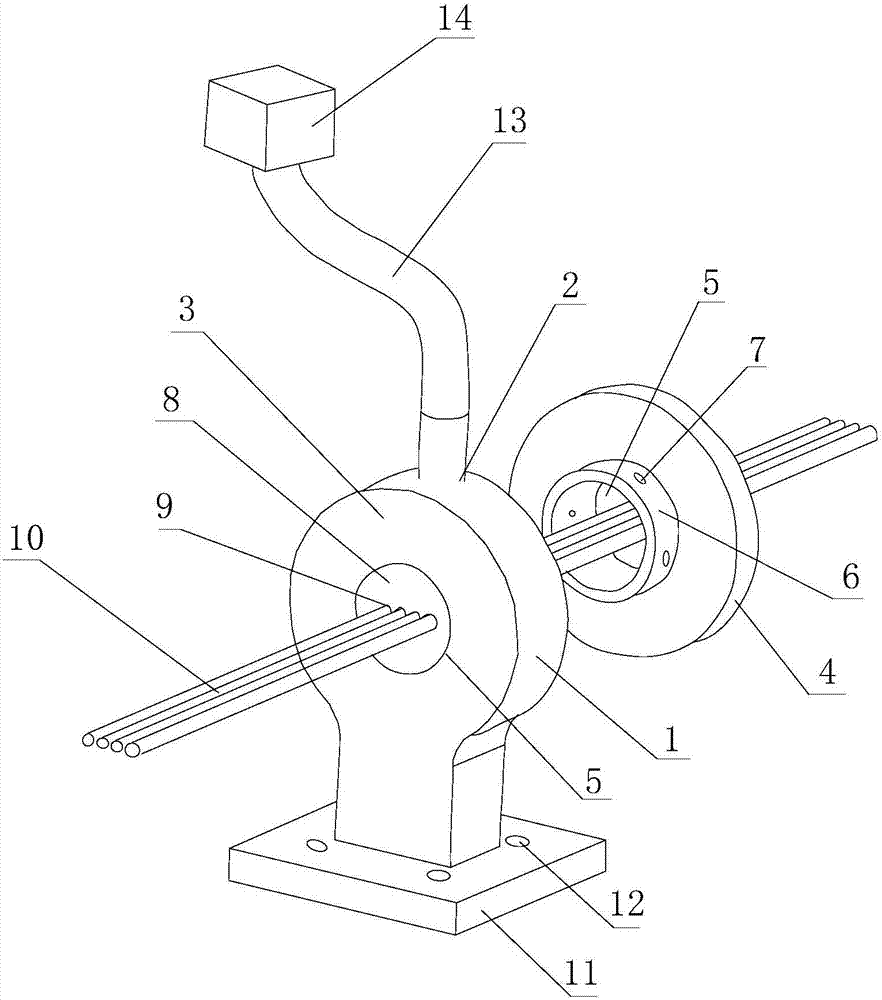

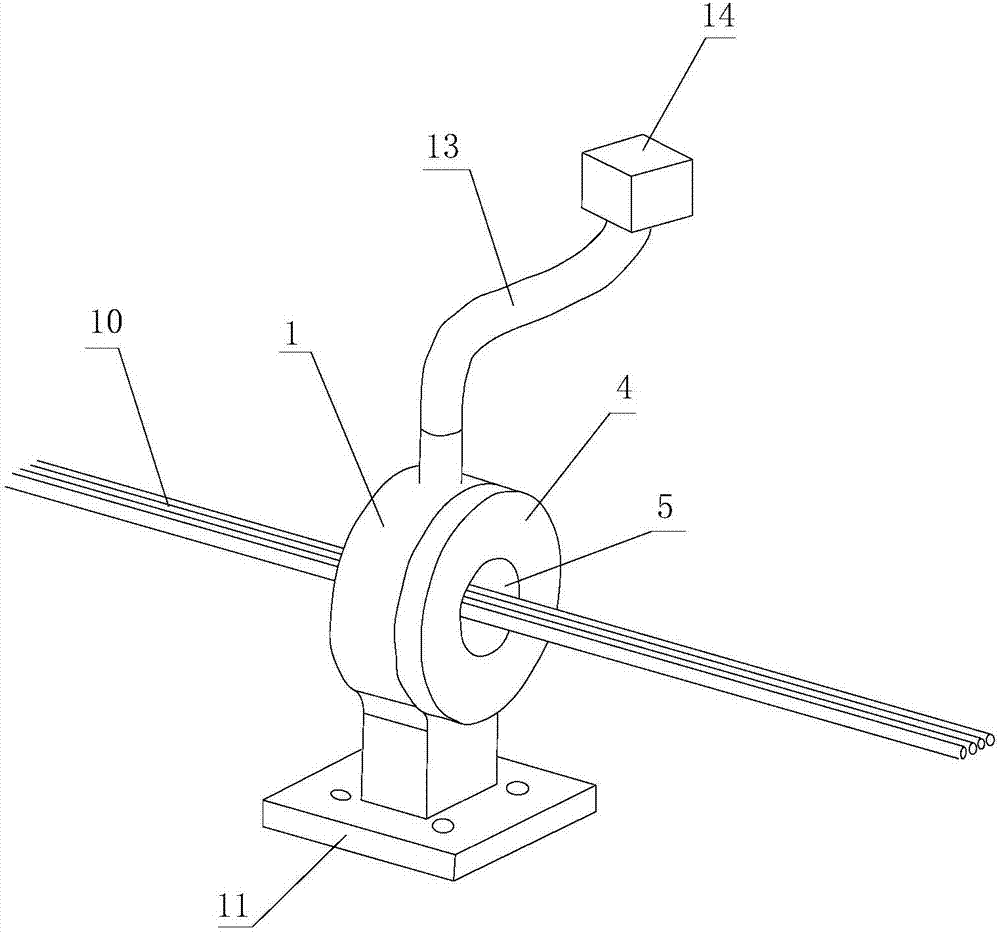

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] The present invention provides a cable gathering device with an integrated air blowing function, which is used to remove the dust on the optical cable raw material 10 and the cable gathering mold 8 when the optical cable raw materials 10 are paralleled, such as the reinforcement of the optical cable and the dust on the surface of the reinforcement to clear.

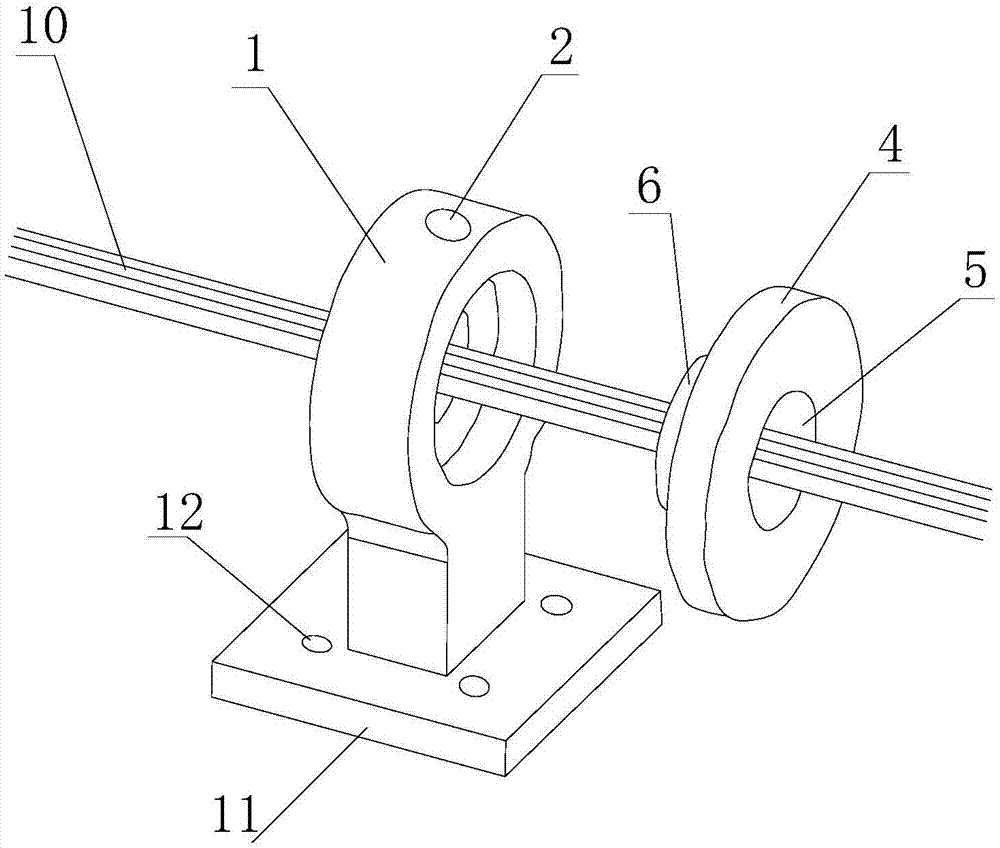

[0027] see figure 1 and figure 2 Shown is the schematic diagram of the cross-sectional structure of the wire-gathering device of the present invention. The wire-gathering device of the present invention includes a ring-shaped fixing seat 1 and a front cover 3 and a rear cover 4 with a round hole 5 in the center. Specifically, the fixed Seat 1, front cover 3 and back cover 4 are the same circle of diameter, and the diameter of round hole 5 on front cover 3 and back cover 4 is identical, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com