A prefabricated wall auxiliary installation calibration device and calibration method

A kind of calibration equipment and assembled technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of backward manpower adjustment, reduce construction efficiency, and cannot guarantee installation accuracy, etc., achieve intuitive observation, reduce the number of people, avoid loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

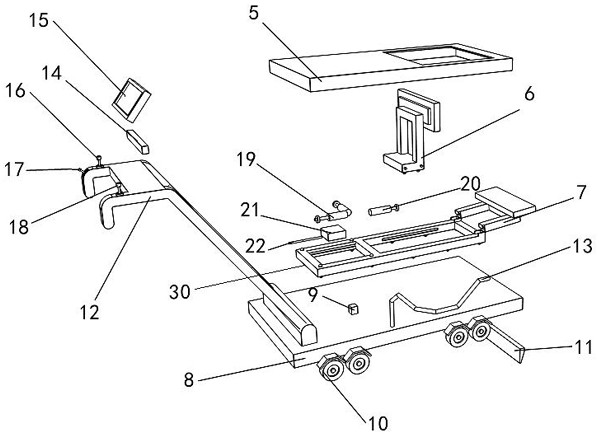

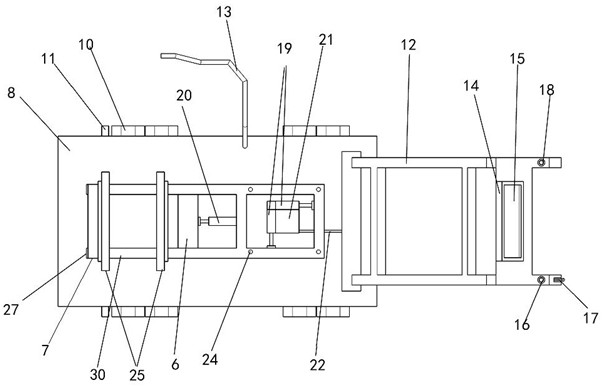

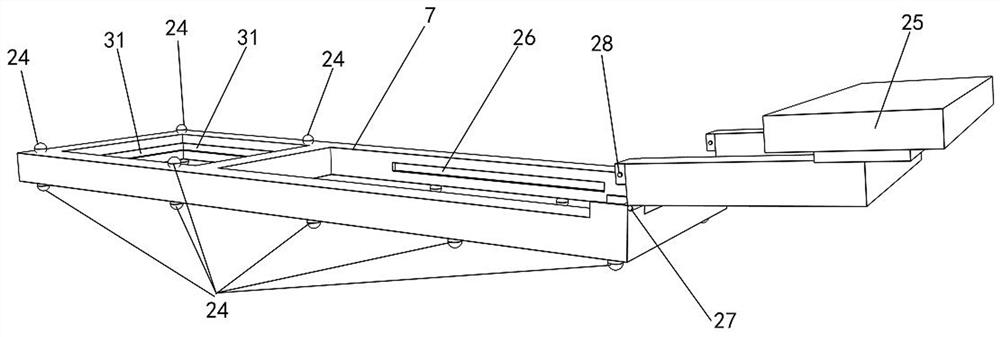

[0039] Such as Figure 1 to Figure 6 As shown, a prefabricated wall auxiliary installation and calibration equipment includes a clamping part for clamping the prefabricated wall 1 and a bearing part for carrying the clamping part; Steering parts that hold the direction of the part.

[0040] The bearing part includes an equipment base 8, a hand push rod 12 and a plurality of wheels 10; Equipment base 8 bottom surface is equipped with pay-off caliper 11, and pay-off caliper 11 inner side is flush with rubber pad 25 inner side on the support A7, and pay-off caliper 11 bottom edge is slightly higher than wheel 10 bottom edge.

[0041] The clamping parts include an equipment upper cover 5, a bracket C30, a bracket B6, a bracket A7 and a hydraulic rod B20. The equipment upper cover 5 is fixed on the equipment base 8, and the bracket C30 is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com