Pre-buried circular ring draining well closing manner

A technology of dredging wells and pre-embedded rings, which is applied in construction, infrastructure engineering, etc., can solve the problems of groundwater prefabricated steel casings leaking into the basement and corrosion, etc., and achieves the effect of simple structure and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

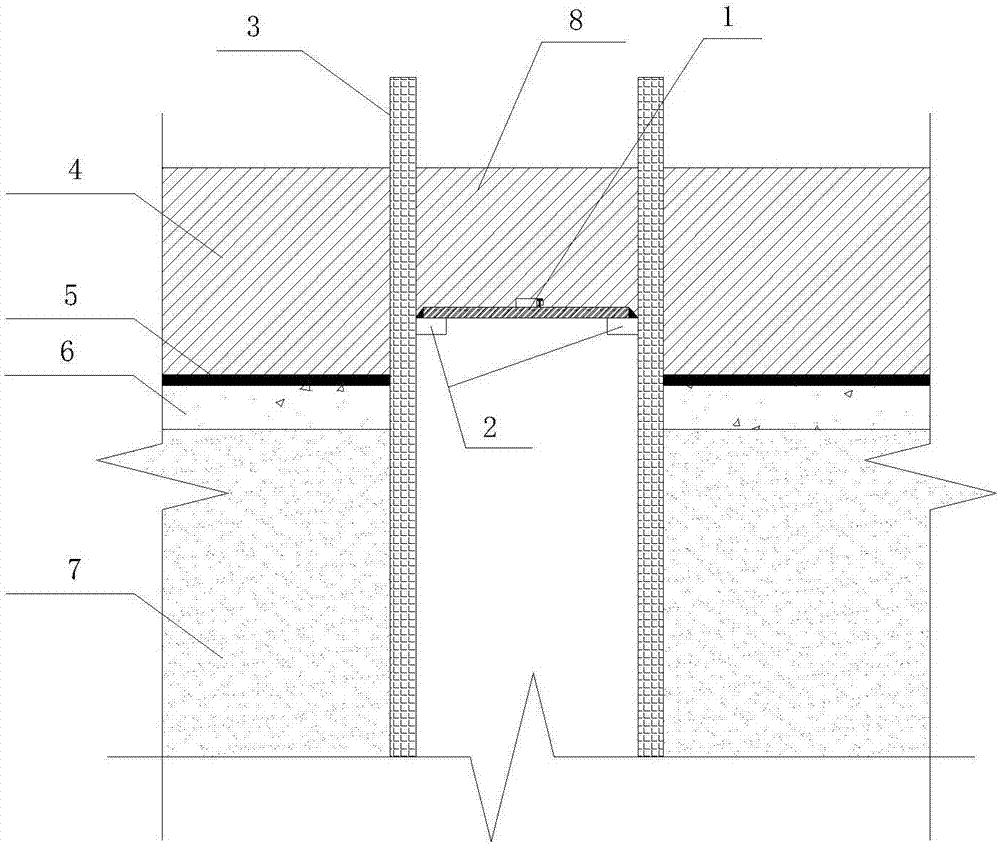

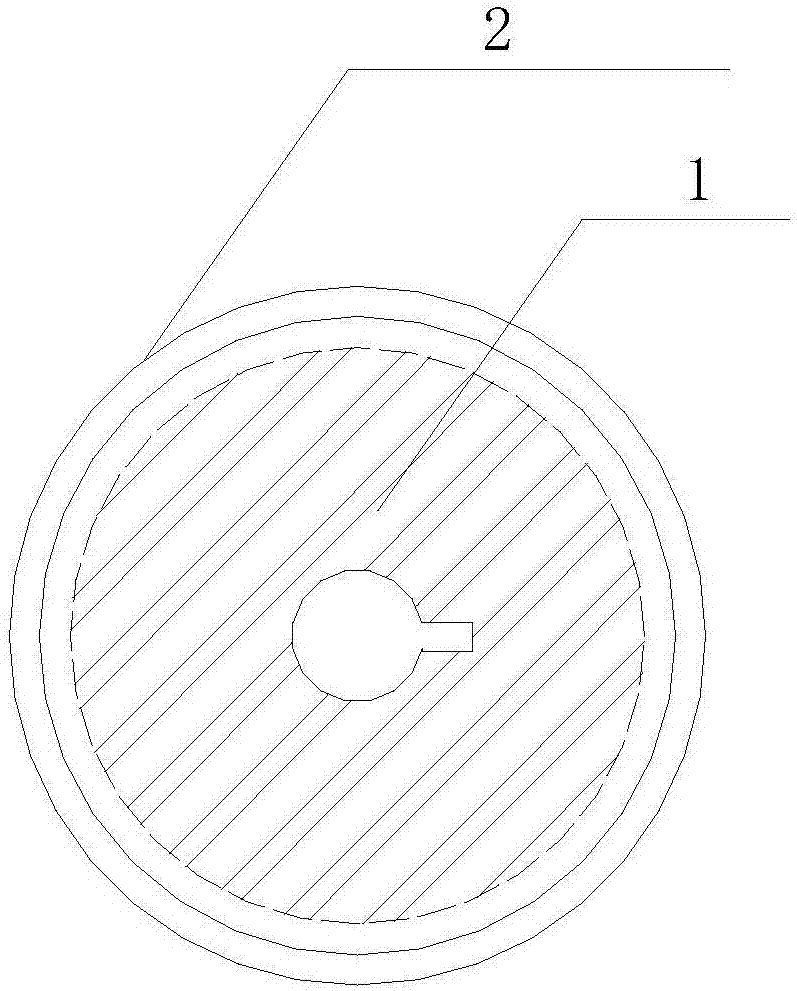

[0027] see Figure 1-3 As shown, a pre-embedded ring drainage well sealing method, including a blind plate 1, a pre-embedded ring 2, a pre-embedded ring 2 is provided on the inner wall of the dehydration well, and the blind plate 1 is arranged on the pre-embedded ring 2 , The embedded ring 2 is fixed on the sandless concrete pipe 3 .

[0028] The outer wall of the dewatering well consists of the base plate 4, the waterproof coiled material 5, the base plate cushion 6, and the base soil 7 from top to bottom.

[0029] Blind plate 1 and pre-embedded ring 2 are fully welded.

[0030] The embedded ring 2 is welded and fixed on the sandless concrete pipe 3 .

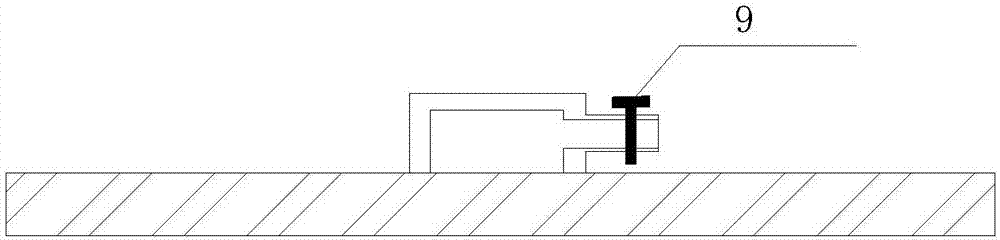

[0031] The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com