Transfer type tipping paper and preparation method thereof

A transfer-type, tipping paper technology, applied in papermaking, paper coating, physical treatment of paper, etc., can solve the problems of poor ink absorption, safety and hygiene indicators that cannot meet the use requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

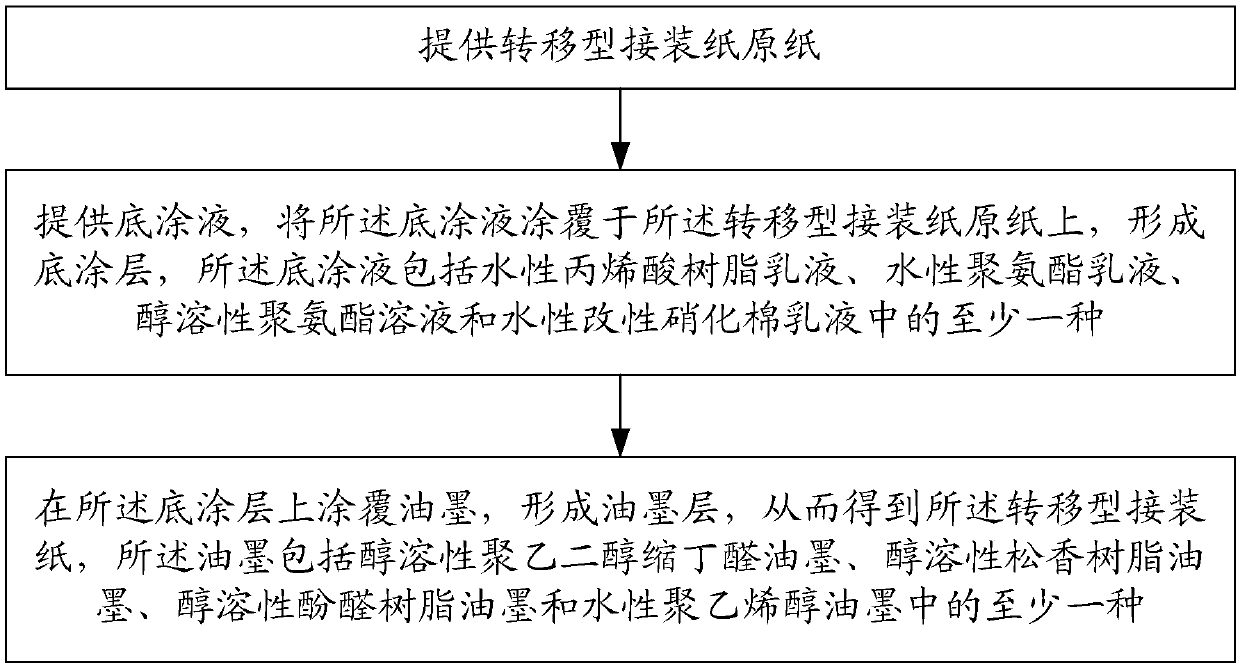

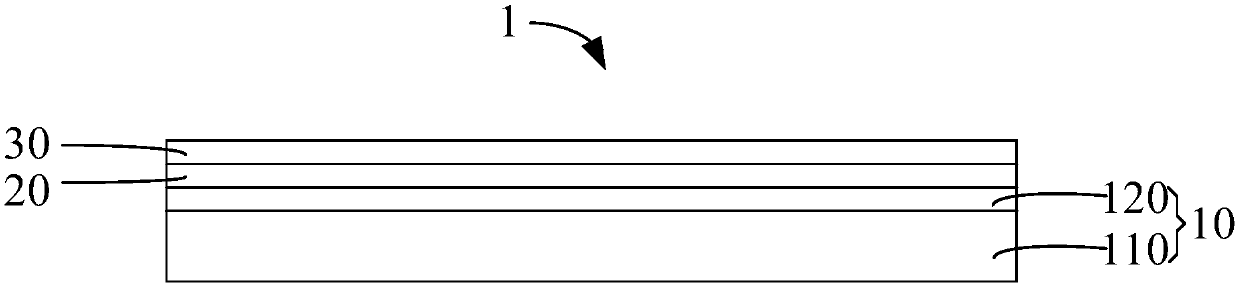

[0022] see Figure 1 to Figure 2 , the first embodiment of the present invention provides a method for preparing transfer-type tipping paper 1, comprising:

[0023] S1, providing base paper 10 for transfer-type tipping paper;

[0024] S2, providing a primer solution, coating the primer solution on the base paper 10 of the transfer tipping paper to form a primer layer 20, the primer solution includes water-based acrylic resin emulsion, water-based polyurethane emulsion, alcohol-soluble At least one of polyurethane solution and aqueous modified nitrocellulose emulsion; and

[0025] S3, coating ink on the primer layer 20 to form an ink layer 30, thereby obtaining the transfer tipping paper 1, the ink includes alcohol-soluble polyethylene glycol butyral ink, alcohol-soluble rosin resin ink , at least one of alcohol-soluble phenolic resin ink and water-based polyvinyl alcohol ink.

[0026] In step S1, the transfer tipping paper base paper 10 may be silver transfer tipping paper ...

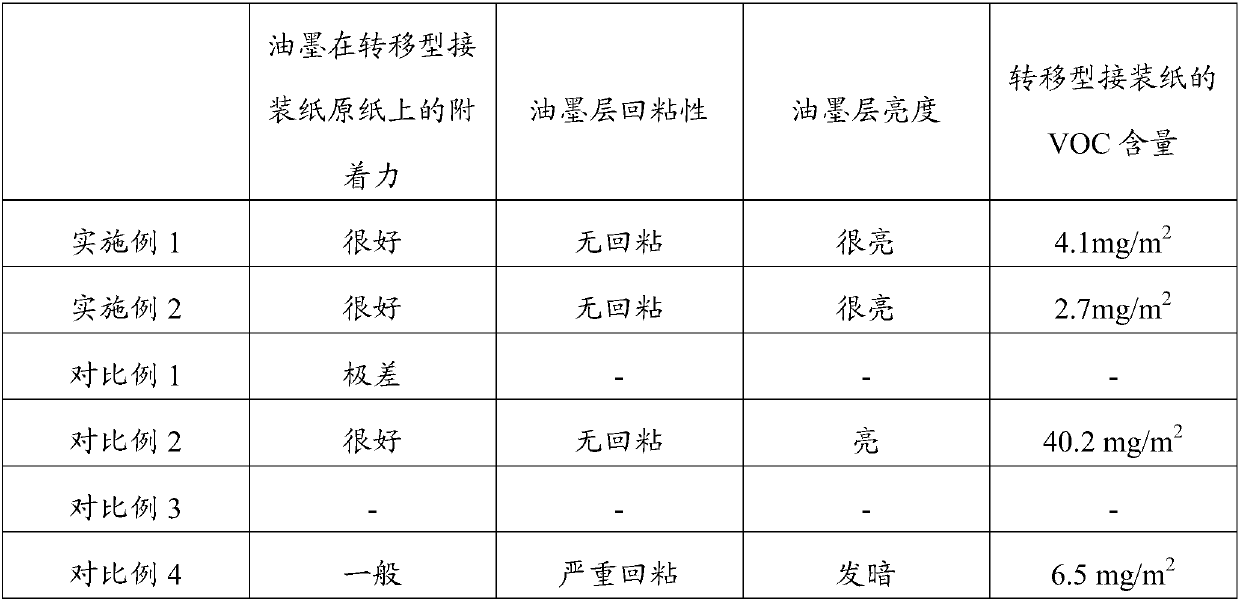

Embodiment 1

[0039] Select the gram weight as 32.5g / m 2 Silver transfer type tipping paper base paper, using water-based acrylic resin emulsion as the primer solution to carry out gravure printing on the silver transfer type tipping paper base paper, and form a primer layer after drying, the solid content of the primer solution is 20 %, the drying temperature is 115°C, and the dry film weight of the base coat is 0.8g / m 2 ; Use alcohol-soluble polyethylene glycol butyral ink system to carry out gravure printing on the primer layer, form an ink layer after drying, and obtain transfer-type tipping paper.

Embodiment 2

[0041] Select the gram weight as 34.5g / m 2 Golden transfer type tipping paper base paper, using water-based polyurethane emulsion as the primer liquid to carry out gravure printing on the golden transfer type tipping paper base paper, forming a primer layer after drying, and the solid content of the primer solution is 24% , the drying temperature is 125°C, and the dry film weight of the primer layer is 1.0g / m 2 ; Use alcohol-soluble rosin resin ink system to carry out gravure printing on the primer layer, form an ink layer after drying, and obtain transfer-type tipping paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com