A low-smoke density halogen-containing flame-retardant reinforced PBT/PET compound and its preparation method and application

A smoke density and compound technology, which is applied in the field of engineering plastics, can solve the problems of not paying attention to the amount of smoke or smoke density index, and the smoke density cannot be satisfied, and achieve the effect of high appearance gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

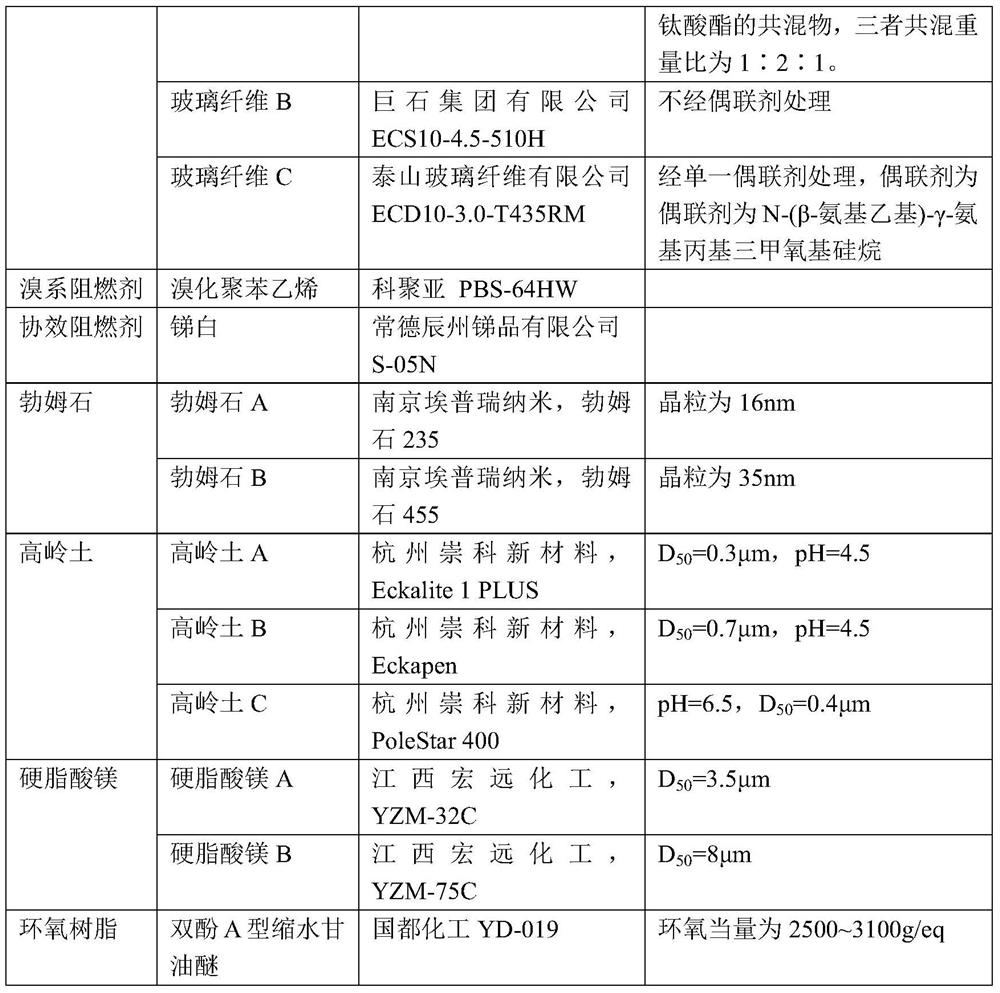

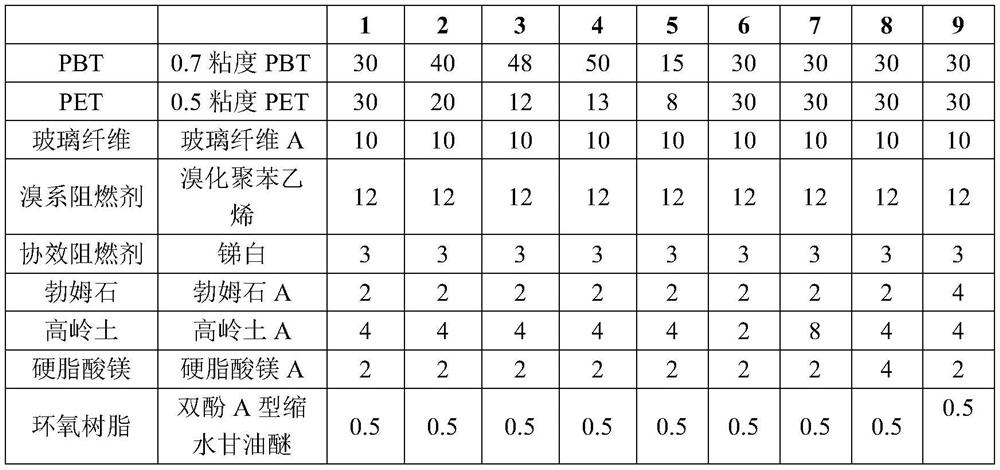

[0058] The content of each component in the PBT / PET composites of Examples 1-18 is shown in Table 1.

[0059] The preparation method is as follows: according to Table 1, the brominated flame retardant and the synergistic flame retardant are mixed to make the first premix; the epoxy resin is mixed with boehmite, kaolin, and magnesium stearate to make the second premix. Mixture; PBT, PET, glass fiber, the first premix, and the second premix are added to the twin-screw extruder, mixed and dispersed, melt-extruded and granulated to obtain low-smoke density halogen-containing flame-retardant reinforced PBT / PET compound.

[0060] Among them, the temperature of the first zone of the twin-screw extruder from the feeding port to the machine head is 200-230°C, the temperature of the second zone is 240-260°C, the temperature of the third zone is 235-255°C, and the temperature of the fourth zone is 235-255°C , the temperature in zone five is 235-255°C, the temperature in zone six is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com