Intelligent laying and recovery device for unmanned ship

An unmanned boat, intelligent technology, applied in the direction of ships, davits, transportation and packaging, can solve the problems of occupying too much deck space, long operation time, large size of the hanging cage, etc., to improve the efficiency of deployment and recovery, Reduce labor intensity and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

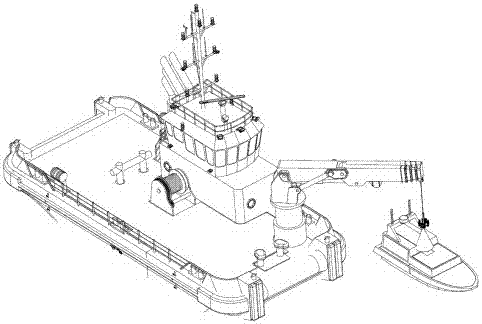

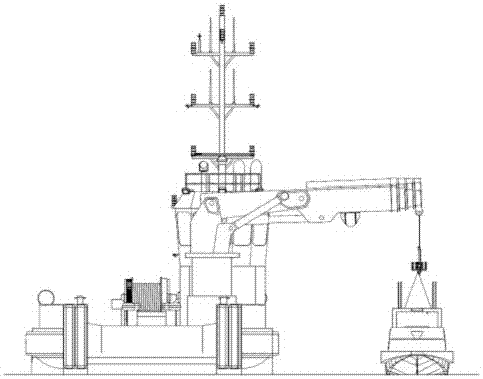

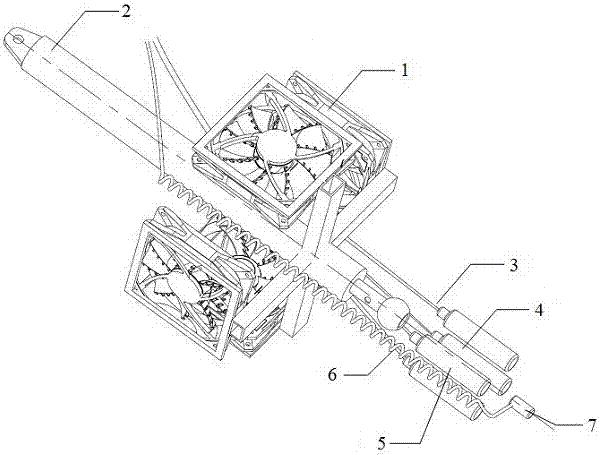

[0022] Such as Figure 1 to Figure 4 As shown, an unmanned boat intelligent deployment and recovery device includes a hoisting tracking mechanism and a clamping mechanism for the central lifting point of the unmanned boat. The hoisting tracking mechanism includes: a vector frequency conversion fan 1, and a rapid ejection telescopic rod assembly 2 , laser indicator light 3, camera 4, laser rangefinder 5, spotlight indicator light 6, docking locking and unlocking induction head 7, the upper part of the fast ejection telescopic rod assembly 2 is provided with a hook connected to the mother ship, and the lower part is provided with Cross bracket, four vector frequency conversion fans 1 are fixed on the cross bracket at the bottom of the rapid ejection telescopic rod assembly 2, and two vector frequency conversion fans 1 are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com