Precast concrete ecological step-type slope protection mold device

A technology of prefabricated concrete and slope protection moulds, which is applied in the direction of moulds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of long time required, high technical level requirements of workers, and low work efficiency, and achieve easy operation, simple structure, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

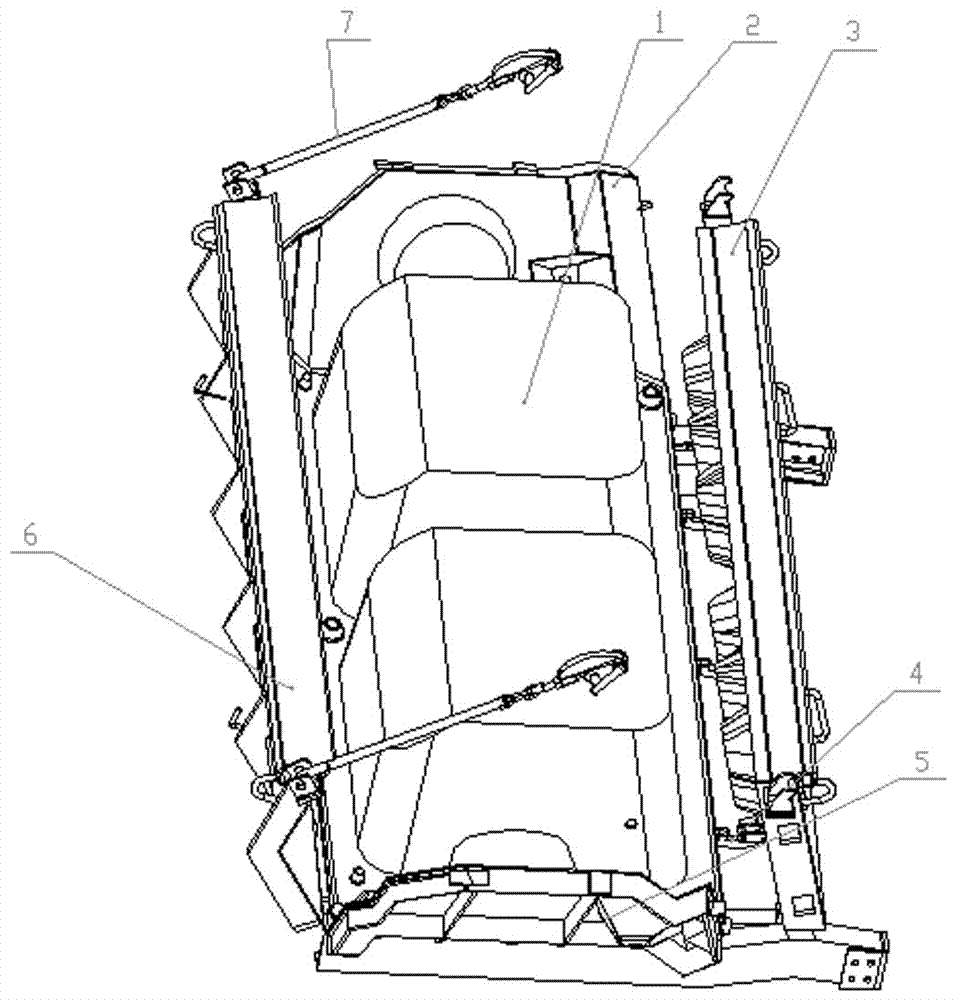

[0027] With reference to the accompanying drawings, a precast concrete ecological stepped slope protection mold device includes an inner mold body 1, a right mold body 2, a front mold body 3, a lower end locking device 4, a left mold body 5, a rear mold body 6 and an upper The mold locking device 7, the left mold body 5 and the right mold body 2 are respectively arranged on the left and right sides of the inner mold body 1, the front mold body 3 and the rear mold body 6 are respectively arranged at the front and rear ends of the inner mold body 1, and the upper mold locking device 7 is movably connected with the rear mold body 6, and the lower end locking device 4 is movably connected with the inner mold body 1.

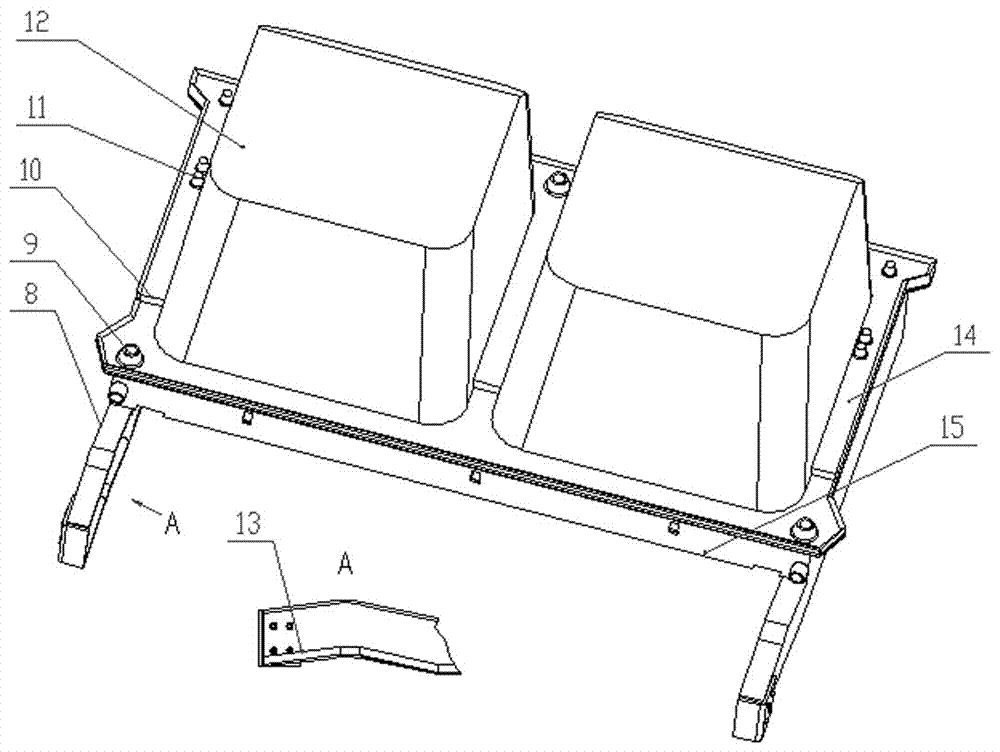

[0028] The inner mold body 1 includes an inner mold core 12 and a base plate 14, the inner mold core 12 is fixed on the base plate 14, a base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com